Driving Infrastructure Development: The Role of Advanced Pipe Extrusion Lines

In the rapidly evolving landscape of global infrastructure, the demand for high-quality, durable, and efficient piping systems is at an all-time high. From urban water supply networks to complex industrial fluid management, plastic pipes have become indispensable. At the heart of this industry lies the technology of pipe extrusion, particularly the sophisticated capabilities of a **ppr pipe production line**. This comprehensive guide delves into the nuances of modern pipe manufacturing, focusing on cutting-edge solutions like the Hdpe High Speed Solid Wall Pipe Extrusion Production Line, and also explores the wider context of related technologies such as a **pvc pipe extrusion machine for sale** and the versatility of a **pvc extruder machine for sale**.

Our aim is to provide an authoritative resource, demonstrating deep expertise and practical experience in pipe extrusion technology, supported by industry standards and a commitment to trust. We'll navigate through industry trends, technical specifications, application versatility, and the critical factors for selecting the right manufacturing partner.

Global Industry Trends in Plastic Pipe Manufacturing

The plastic pipe market is projected to reach approximately USD 120 billion by 2027, driven by urbanization, industrial growth, and increasing investments in water and wastewater infrastructure globally. Key trends shaping this industry include:

- Sustainability and Recycling: Growing emphasis on eco-friendly production, use of recycled materials, and energy-efficient manufacturing processes. Innovations in co-extrusion and multi-layer pipes also contribute to material efficiency.

- High-Performance Materials: Demand for pipes made from advanced polymers like HDPE, PPR, and PVC, offering enhanced pressure resistance, temperature tolerance, and chemical inertness. This directly impacts the requirements for a robust **ppr pipe production line** or a versatile **pvc extruder machine for sale**.

- Automation and Industry 4.0 Integration: Increased adoption of smart factories, IoT, AI, and machine learning for optimized production, predictive maintenance, and quality control, leading to higher efficiency and reduced operational costs. Gravimetric dosing systems and advanced PLC controls are now standard.

- Specialized Applications: Growth in niche markets like trenchless technology, pre-insulated pipes, and pipes for renewable energy systems, requiring highly specialized extrusion lines.

- Quality and Standardization: Strict adherence to international standards such as ISO, ASTM, and DIN ensures product reliability and safety across diverse applications.

Technical Parameters and Capabilities: The Core of Extrusion Excellence

A high-performance extrusion line is defined by its ability to deliver consistent quality, high output, and operational efficiency. Let's delve into the key technical parameters that characterize a state-of-the-art **ppr pipe production line** and how it compares with other common systems like a **pvc pipe extrusion machine for sale**.

Typical Parameters for a Modern PPR Pipe Production Line

Our Hdpe High Speed Solid Wall Pipe Extrusion Production Line exemplifies the precision and efficiency required for modern pipe manufacturing. While specifically designed for HDPE, its underlying principles and advanced features are highly analogous to a premium **ppr pipe production line**.

| Parameter | Description | Typical Range (PPR/HDPE) |

|---|---|---|

| Extruder Type | High-efficiency single screw extruder (L/D ratio 36:1 to 40:1) with specialized screw design for polyolefins (PPR, HDPE). | SJ series, conical/parallel twin screw for PVC |

| Output Capacity | Maximum production output per hour, depending on pipe diameter and wall thickness. | 100 kg/h to 1200 kg/h+ |

| Pipe Diameter Range | Range of pipe diameters the line can produce. | 16mm to 630mm+ |

| Wall Thickness Range | Range of pipe wall thicknesses. | 1.5mm to 60mm |

| Line Speed | Maximum linear speed of pipe production. | 5 m/min to 20 m/min (small dia.) |

| Control System | Advanced PLC control system with touch screen HMI for precise process management. | Siemens, Schneider, Delta |

| Gravimetric Dosing | System for precise material feeding and additive blending. | Accuracy up to ±0.5% |

| Vacuum Calibration Tank | Length and number of chambers for effective pipe sizing and cooling. | 6m to 12m (multi-chamber) |

| Cooling Tank | Length and design (spray/immersion) for efficient pipe cooling. | Up to 15m+ |

| Haul-off Unit | Number of claws and traction force for stable pulling. | 2-claw to 10-claw, up to 20,000N |

| Cutter Type | Dust-free planetary cutter or chip-less cutter for precise lengths. | Planetary, saw blade, chipless |

| Power Consumption | Overall power consumption of the entire line. | 150 kW to 600 kW+ |

Comparison: PPR Pipe Extrusion Line vs. PVC Extrusion Line

While both PPR and PVC pipes are widely used, their material properties necessitate different machine configurations. Understanding these differences is crucial when evaluating a **ppr pipe production line** versus a **pvc pipe extrusion machine for sale**.

| Feature | PPR/HDPE Pipe Production Line | PVC Pipe Extrusion Machine for Sale |

|---|---|---|

| Extruder Type | Typically single screw (optimized for polyolefins). | Mainly conical twin-screw or parallel twin-screw (due to PVC's thermal sensitivity). |

| Screw Design | High L/D ratio, specific geometry for melting and homogenizing polypropylenes/polyethylenes. | Specialized screw profiles for PVC, often with cooling channels, to prevent degradation. |

| Die Head | Spiral or basket-type die, designed for smooth flow and concentricity of polyolefin melts. | Often spider or co-extrusion dies, optimized for PVC flow characteristics and complex profiles. |

| Cooling System | Efficient vacuum sizing and water spray/immersion cooling for rapid solidification. | More extensive and often multi-stage cooling to manage PVC's higher specific heat capacity and avoid distortion. |

| Haul-off Unit | Multi-claw (2-10) for stable pulling of slippery polyolefin pipes. | Often multi-belt for better grip on less flexible PVC pipes. |

| Cutter | Planetary cutter (dust-free) or chipless cutter for clean cuts. | Saw cutter or planetary cutter, sometimes with dust collection for PVC dust. |

| Applications | Hot/cold water supply, heating systems, gas distribution (HDPE). | Drainage, sewage, electrical conduits, industrial piping, pressure pipes. |

| Material Handling | Less prone to degradation during processing. | Requires precise temperature control to avoid thermal degradation and HCl release. |

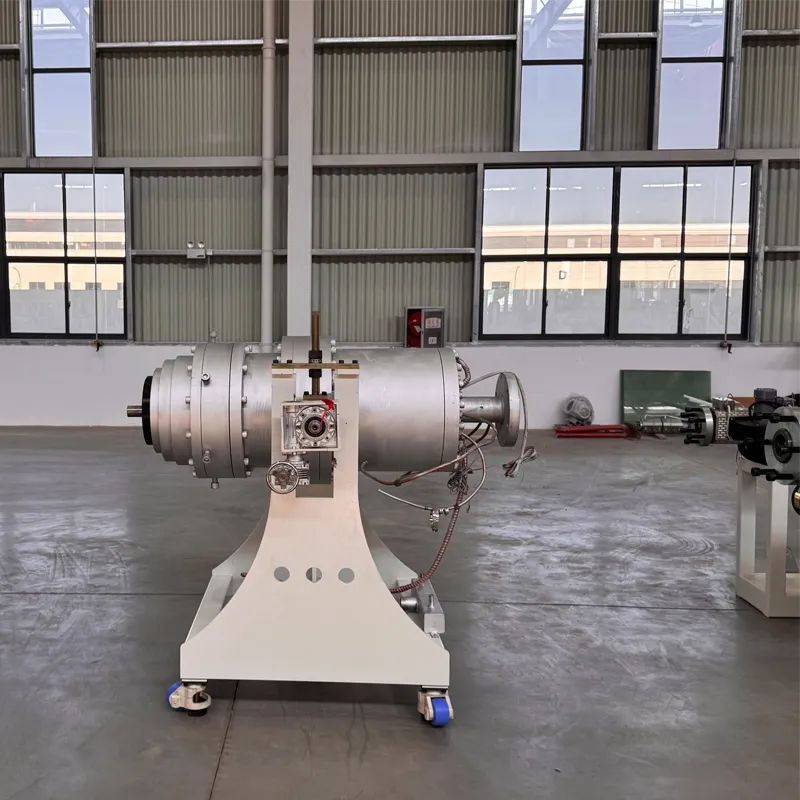

Advanced single-screw extruder, the heart of a high-speed pipe production line.

Versatile Application Scenarios for Plastic Pipe Extrusion

The output of a **ppr pipe production line**, or any pipe extrusion machinery, finds its application across an incredibly broad spectrum of industries, underpinning critical infrastructure worldwide. Each material brings unique advantages to specific scenarios:

- Residential and Commercial Plumbing (PPR): PPR pipes are synonymous with hot and cold water supply systems in buildings due to their excellent heat resistance, low thermal conductivity, and corrosion resistance. A high-speed **ppr pipe production line** ensures the consistent quality and volume needed for modern construction.

- Water Supply and Distribution (HDPE, PVC): HDPE pipes, often produced by lines like our Hdpe High Speed Solid Wall Pipe Extrusion Production Line, are ideal for municipal water supply, agricultural irrigation, and industrial water transport due to their flexibility, resistance to chemicals, and long service life (often 50+ years). PVC pipes from a **pvc pipe extrusion machine for sale** are also widely used for their cost-effectiveness and good pressure rating in water distribution networks.

- Gas Distribution (HDPE): The superior leak-free joints (via fusion welding) and resistance to stress cracking make HDPE pipes the material of choice for natural gas distribution. The precision of the extrusion process is paramount here.

- Wastewater and Drainage (PVC, HDPE): PVC pipes are extensively used for sewer and drainage systems due to their smooth bore, resistance to abrasion, and chemical resistance. Large-diameter PVC pipes from a robust **pvc extruder machine for sale** are common in these applications. HDPE also offers excellent solutions for corrosive wastewater environments.

- Industrial Applications (HDPE, PVC, PPR): In chemical plants, mining operations, and power generation, plastic pipes handle aggressive chemicals, slurries, and high-pressure fluids. The ability of an extrusion line to produce pipes compliant with stringent industrial standards like ISO 4427 (for PE) and ASTM F891 (for PVC) is critical.

- Conduit and Electrical Protection (PVC): The insulating properties and ease of installation make PVC pipes ideal for protecting electrical cables and communication lines. A reliable **pvc extruder machine for sale** is fundamental to this sector.

Technical Advantages: Why Modern Extrusion Lines Excel

The latest generation of pipe extrusion lines offers significant technical advantages that translate directly into operational benefits and superior end-products. Our Hdpe High Speed Solid Wall Pipe Extrusion Production Line embodies these advancements, applicable to the broader domain of **ppr pipe production line** technology:

- High Speed & High Output: Optimized screw designs, powerful motors, and efficient cooling systems allow for significantly higher production speeds and volumes. For instance, our HDPE line can produce small diameter pipes at speeds up to 20 m/min.

- Precision & Consistency: Advanced gravimetric dosing systems ensure exact material feeding, leading to consistent wall thickness, diameter, and melt homogeneity. PLC (Programmable Logic Controller) control provides real-time monitoring and adjustment of every parameter, minimizing variations.

- Energy Efficiency: Modern extruders feature optimized heating zones, highly efficient motors (e.g., IE3/IE4 standard), and improved barrel cooling systems, reducing overall power consumption significantly compared to older models. This aligns with global energy-saving initiatives.

- Automation & Reduced Labor: From automatic material loading to integrated cutting and stacking/coiling units, automation reduces manual intervention, minimizes errors, and lowers labor costs.

- Versatility: A well-designed line can often be adapted to produce different pipe sizes and even different materials (with appropriate die and screw changes) within a specific polymer family, offering flexibility to manufacturers.

- Long Lifespan & Low Maintenance: Constructed with high-quality, wear-resistant components (e.g., bimetallic screws and barrels), these lines are designed for continuous operation with minimal downtime, ensuring a robust return on investment.

Precision vacuum calibration tank ensuring accurate pipe dimensions and cooling.

The Manufacturing Process: From Granules to Finished Pipe

The journey from raw polymer granules to a finished, high-quality plastic pipe is a complex yet highly automated process, crucial for any **ppr pipe production line** or equivalent. Here’s a detailed breakdown, using the Hdpe High Speed Solid Wall Pipe Extrusion Production Line as our specific example:

Detailed Process Flow for Pipe Extrusion

-

Material Feeding & Drying:

- Process: Raw polymer granules (e.g., HDPE, PPR, PVC compound) are fed from a hopper into the extruder's barrel. For some materials like PVC, proper drying is crucial to prevent moisture-related defects.

- Materials: High-grade virgin HDPE/PPR/PVC resin, often combined with masterbatches (for color) and stabilizers. Adherence to material standards like ISO 4427 (for PE), EN ISO 15874 (for PPR), and ASTM D1784 (for PVC) is critical.

- Technology: Gravimetric dosing units ensure precise feeding and consistent material blend, directly impacting the final pipe's physical properties.

-

Extrusion (Melting & Homogenizing):

- Process: Inside the heated barrel, a rotating screw (or twin screws for PVC) melts the polymer through a combination of heat from heaters and shear friction. The material is compressed, degassed, and homogenized.

- Manufacturing Process: This is the core "extrusion" step. The screw's design (e.g., barrier screw, mixing sections) is critical for achieving a uniform, bubble-free melt. For HDPE/PPR, single-screw extruders are typical; for PVC, conical or parallel twin-screw extruders are used to manage its thermal sensitivity and high viscosity.

- Key Parameters: Barrel temperature profiles (zones), screw speed, melt pressure.

-

Die Forming (Shaping):

- Process: The homogenized melt is forced through a precisely machined die head, which shapes it into a continuous pipe profile. Co-extrusion dies allow for multi-layer pipes (e.g., with a color strip or protective layer).

- Manufacturing Process: High-precision CNC machining is essential for die and mold manufacturing to ensure exact pipe dimensions and smooth surface finish.

- Detection Standards: Regular calibration and dimensional checks of the die using precision measuring tools.

-

Vacuum Calibration:

- Process: Immediately after exiting the die, the still-molten pipe enters a vacuum calibration tank. Vacuum pressure pulls the pipe against the inner wall of a sizing sleeve, ensuring precise outer diameter and roundness. Cooling water simultaneously begins to solidify the outer layer.

- Technology: High-efficiency vacuum pumps and precise water temperature control.

-

Cooling:

- Process: The pipe then passes through multiple cooling tanks, typically using water spray or immersion. This step progressively cools the pipe, solidifying its entire wall thickness and setting its final dimensions.

- Lifespan Impact: Proper, gradual cooling minimizes internal stresses in the pipe, which is vital for its long-term performance and service life (often 50 years or more for HDPE/PPR).

-

Hauling Off:

- Process: A haul-off unit (multi-claw or multi-belt) steadily pulls the pipe through the entire line at a consistent speed, ensuring uniform wall thickness and preventing stretching or sagging.

- Technology: High-precision servo motors and synchronized speed control with the extruder.

-

Cutting:

- Process: A planetary cutter (for dust-free operation common with PPR/HDPE) or a saw cutter precisely cuts the continuous pipe into predetermined lengths.

- Application Scenarios: This ensures pipes are ready for various construction or industrial applications requiring specific lengths.

-

Stacking/Coiling:

- Process: For larger diameter pipes, automatic stacking units prepare them for transport. For smaller, flexible pipes, coiling machines wind them into compact rolls.

- Efficiency: This final automation step streamlines post-production handling.

Synchronized haul-off unit and precision cutting system for consistent pipe lengths.

Inspection Standards & Quality Control: Throughout this process, strict quality control measures are applied. This includes continuous online measurement of pipe diameter and wall thickness, ensuring compliance with international standards such as ISO 4427 (PE), ISO 15874 (PPR), ASTM F891 (PVC), and DIN 8077/8078. Products undergo rigorous testing for pressure resistance, impact strength, and material purity before leaving the factory. Our commitment to ISO 9001 certified manufacturing processes ensures that every pipe produced on our lines meets the highest benchmarks for reliability and performance.

Choosing Your Partner: Manufacturer Comparison

Selecting the right supplier for a **ppr pipe production line**, a **pvc pipe extrusion machine for sale**, or any industrial extrusion equipment is a critical business decision. It's not just about the machinery; it's about the comprehensive support and expertise offered.

Key Considerations for Manufacturer Comparison:

- Research & Development Capabilities: A leading manufacturer invests heavily in R&D to innovate and improve their machines. Look for evidence of patented technologies, advanced software integration, and a proactive approach to industry trends. Our engineers constantly work to optimize energy consumption and output efficiency.

- Quality Control & Certifications: Verify if the manufacturer adheres to international quality management systems like ISO 9001. Check for product certifications such as CE marking, which indicates compliance with EU health, safety, and environmental protection standards. Our production facilities are ISO 9001 certified, ensuring meticulous attention to detail at every stage.

- Experience & Track Record: A long history in the industry with a strong portfolio of successful installations globally speaks volumes about a company's reliability and expertise. We boast over two decades of experience in the plastic machinery sector, with numerous successful projects worldwide.

- Customization & Flexibility: Can the manufacturer tailor the line to your specific requirements – pipe diameter, output capacity, material versatility, or level of automation? A flexible approach to customization is a strong indicator of client-centric service.

- After-Sales Support & Service: This is paramount. Look for a manufacturer offering comprehensive installation, commissioning, training, spare parts availability, and responsive technical support. Our dedicated service team offers 24/7 online support, field installation, and maintenance services, ensuring minimal downtime for your operations.

- Technological Prowess: Assess the integration of advanced technologies like Industry 4.0 principles, smart diagnostics, and remote monitoring capabilities.

Customization Solutions: Tailoring for Your Success

Recognizing that every client's needs are unique, we specialize in providing highly customized solutions for a **ppr pipe production line** and other extrusion systems. Our approach ensures that your investment perfectly aligns with your production goals and market demands:

- Output Capacity Customization: Whether you require a high-volume line for mass production or a more modest setup for specialized products, we can configure the extruder size, cooling system, and downstream equipment to match your desired output.

- Pipe Diameter & Wall Thickness Range: We offer lines capable of producing a vast range of pipe diameters (e.g., from 16mm to 630mm+ for HDPE/PPR) and wall thicknesses, ensuring you can meet diverse market demands.

- Material Versatility: While our Hdpe High Speed Solid Wall Pipe Extrusion Production Line excels in HDPE, we can adapt lines for PPR, PP, PE, and with different configurations, even a high-performing **pvc extruder machine for sale** to handle rigid or flexible PVC. This often involves specific screw and die designs.

- Automation Level: From semi-automatic setups to fully integrated, smart production lines with gravimetric dosing, automatic cutting, stacking/coiling, and remote monitoring, we scale automation to your operational needs and budget.

- Specific Application Requirements: If you need special features like co-extrusion for multi-layer pipes, advanced pipe marking systems, or integrated pipe winding solutions for flexible pipes, our engineering team can design and integrate these functionalities.

Our project managers work closely with clients from initial consultation to final commissioning, providing detailed layout plans, equipment specifications, and performance guarantees. This consultative approach ensures that the delivered **ppr pipe production line** or related system is an optimal fit for your business.

Application Cases and Customer Success

Our commitment to excellence is reflected in the success of our clients globally. While specific client names remain confidential, we can illustrate the impact of our extrusion lines through typical application scenarios:

- Case Study 1: Large-Scale Infrastructure Project (HDPE/PPR)

A leading infrastructure company in Southeast Asia required a high-capacity **ppr pipe production line** equivalent (specifically, our Hdpe High Speed Solid Wall Pipe Extrusion Production Line) to supply pipes for a new city-wide water distribution network. Our solution involved a complete line capable of producing HDPE pipes up to 450mm diameter at high speeds. The integration of gravimetric dosing and a precision cooling system ensured compliance with ISO 4427 standards for potable water. The client reported a 20% increase in production efficiency and a significant reduction in material waste within the first six months of operation, directly attributing it to the line's stability and advanced control features.

- Case Study 2: New Market Entry (PVC)

A manufacturing group in Eastern Europe sought to diversify its product portfolio by entering the PVC conduit market. They invested in our advanced **pvc pipe extrusion machine for sale**. This line was customized with a specific twin-screw extruder optimized for high-speed production of electrical conduits (16mm-63mm). Our comprehensive training program for their technical team enabled them to quickly master the complex operation. Within a year, the client became a major supplier in their region, praising the machine's reliability and the rapid ROI facilitated by its high output and low energy consumption.

- Case Study 3: Modernizing an Existing Facility (PPR)

An established pipe manufacturer in the Middle East decided to upgrade their aging PPR pipe production lines to meet stricter quality regulations and increase capacity. They chose our state-of-the-art **ppr pipe production line** replacement components, including a new high-efficiency extruder and an upgraded vacuum calibration system. The seamless integration and our dedicated commissioning support minimized downtime. The client noted an immediate improvement in pipe concentricity and a substantial reduction in energy costs, reinforcing their competitive edge in a demanding market.

Finished HDPE pipes, demonstrating the versatility and quality of modern extrusion lines.

Frequently Asked Questions (FAQ)

Q1: What is the typical lifespan of a pipe produced by a high-quality HDPE/PPR pipe production line?

A1: Pipes produced by high-quality extrusion lines, such as our Hdpe High Speed Solid Wall Pipe Extrusion Production Line, are designed for exceptional longevity. HDPE and PPR pipes, when manufactured to international standards (e.g., ISO 4427 for PE, ISO 15874 for PPR) and installed correctly, typically have a service life of 50 years or more, even under challenging operating conditions like varying temperatures and pressures.

Q2: Can a single extruder line produce pipes of different materials, such as PPR and PVC?

A2: While some flexibility exists, a single extruder line is generally optimized for a specific type of polymer. For instance, a **ppr pipe production line** designed for polyolefins (PPR, HDPE, PE) typically uses a single-screw extruder. A **pvc pipe extrusion machine for sale** usually requires a conical or parallel twin-screw extruder due to PVC's thermal sensitivity and different processing characteristics. While some downstream equipment might be interchangeable, the core extruder and die head are material-specific.

Q3: What are the key inspection standards a reliable pipe production line should adhere to?

A3: A reliable pipe production line should facilitate the production of pipes that meet various international standards. Key standards include ISO (e.g., ISO 4427 for PE, ISO 15874 for PPR, ISO 1452 for PVC), ASTM (American Society for Testing and Materials), and DIN (German Institute for Standardization). The line itself should comply with safety and quality certifications like CE marking and be manufactured under ISO 9001 quality management systems.

Q4: What is the role of gravimetric dosing in a modern **ppr pipe production line**?

A4: Gravimetric dosing systems are crucial for precise material feeding. They measure the material by weight, ensuring highly accurate and consistent flow rates of raw polymer and additives into the extruder. This leads to uniform pipe wall thickness, consistent pipe diameter, and improved material usage efficiency, significantly reducing material waste and enhancing product quality.

Q5: How does a planetary cutter differ from a saw cutter, and why is it preferred for PPR/HDPE pipes?

A5: A planetary cutter performs a clean, dust-free cut by rotating blades around the pipe as it moves, making it ideal for smooth, precise cuts on polyolefin pipes like PPR and HDPE. A saw cutter uses a rotating blade that cuts through the pipe, generating dust. While effective for PVC (often requiring dust collection), the planetary cutter is preferred for PPR/HDPE due to its superior cut quality, reduced noise, and absence of plastic dust, which is beneficial for both product finish and environmental cleanliness.

Q6: What is the significance of the L/D ratio in an extruder for a **ppr pipe production line**?

A6: The L/D ratio (Length to Diameter ratio) of an extruder screw is a critical design parameter. A higher L/D ratio (e.g., 36:1 or 40:1 for polyolefins) provides a longer working section for the screw, allowing for more efficient melting, better homogenization of the polymer melt, and improved devolatilization. This results in higher output rates, better melt quality, and ultimately, superior pipe performance and surface finish.

Q7: What kind of after-sales support can one expect when purchasing a high-speed pipe extrusion line?

A7: Comprehensive after-sales support is a hallmark of a reliable manufacturer. This typically includes professional installation and commissioning services, on-site training for your operators and maintenance staff, readily available spare parts, and responsive technical support (often 24/7 via remote diagnostics or hotlines). A good partner will also offer regular maintenance checks and performance optimization advice to ensure your **ppr pipe production line** or **pvc extruder machine for sale** operates at peak efficiency throughout its lifespan.

Commitment to Trust: Delivery, Warranty, and Support

Our dedication extends beyond delivering cutting-edge machinery. We prioritize transparency and reliability throughout the entire customer journey, building trust through concrete commitments:

- Delivery Cycle: We provide clear and realistic delivery schedules, typically ranging from 60 to 120 days depending on the complexity and customization of the **ppr pipe production line** or **pvc pipe extrusion machine for sale**. Our project management team ensures constant communication and adherence to agreed timelines.

- Quality Assurance & Warranty: Every Hdpe High Speed Solid Wall Pipe Extrusion Production Line, along with all our products, undergoes rigorous testing and quality checks before dispatch. We offer a standard warranty period, typically 12-24 months from commissioning, covering manufacturing defects. Detailed warranty terms are provided with every quotation.

- Customer Support: Our global support network is designed for rapid response. We provide multi-channel support including phone, email, and remote diagnostics. Our experienced engineers are available for on-site installation, commissioning, training, and troubleshooting, ensuring your production line is always operating optimally. We are committed to fostering long-term partnerships through proactive support and continuous service.

Conclusion: Shaping the Future of Pipe Manufacturing

The landscape of plastic pipe manufacturing is dynamic, driven by innovation, sustainability, and ever-increasing demands for quality and efficiency. Investing in an advanced **ppr pipe production line**, or a versatile **pvc extruder machine for sale**, is not just acquiring equipment; it's a strategic move towards future-proofing your operations, enhancing product quality, and achieving sustainable growth. Our Hdpe High Speed Solid Wall Pipe Extrusion Production Line stands as a testament to precision engineering, robust design, and intelligent automation, embodying the best practices in modern pipe extrusion technology.

By understanding the intricate technical parameters, appreciating the breadth of application scenarios, and selecting a partner committed to excellence in every aspect – from R&D to comprehensive after-sales support – businesses can unlock unparalleled potential in the global pipe market. We are dedicated to empowering our clients with the technology and expertise needed to meet and exceed the evolving challenges of infrastructure development.

"The future of plastic pipe manufacturing lies in intelligent automation, sustainable practices, and the relentless pursuit of material science advancements. Manufacturers who embrace these pillars will lead the industry."

— From a panel discussion on "Innovations in Polymer Extrusion Technology" at the Plastics News Extrusion World Congress.

"High-performance plastic pipes, especially HDPE and PPR, are pivotal in addressing global water infrastructure challenges due to their durability, corrosion resistance, and low leakage rates."

— A finding from research published in the Journal of Vinyl and Additive Technology.

-

Innovative Solutions in PVC Pipe Production LineNewsJul.18,2025

-

Innovative Solutions in Pipe Extrusion Production LineNewsJul.18,2025

-

Advanced Plastic Profile Extrusion SolutionsNewsJul.18,2025

-

PVC Profiles: The Future of Durable and Cost-Effective Construction SolutionsNewsJun.06,2025

-

PVC Pipe Extrusion LineNewsJun.06,2025

-

High-Quality Polyethylene Pipe Production LineNewsJun.06,2025

-

High-Performance Tube Production LineNewsJun.06,2025