Composition Of Production Line

The plastic production line is mainly composed of raw material preparation area, pretreatment area, coating area, heating and curing area, cooling area, winding/cutting area and quality inspection area.

- Raw material preparation area: responsible for preparing raw materials needed for production, including the base materials to be plasticized (such as steel wire and paper) and plastic materials (such as PE and PVC film).

- Pretreatment area: pretreat the substrate, such as cleaning, derusting and drying, to ensure the cleanliness and adhesion of the substrate surface.

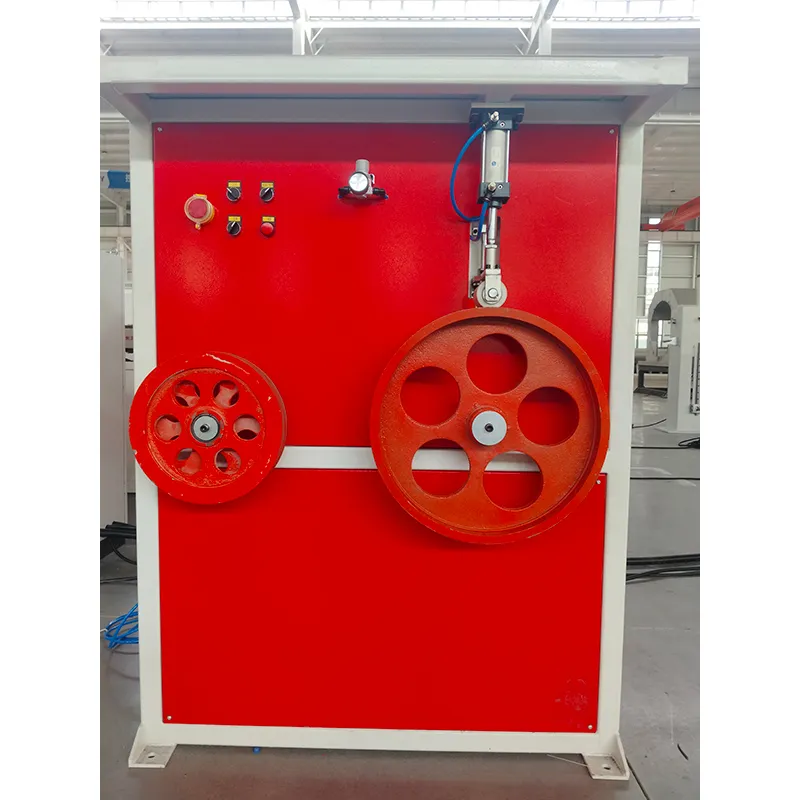

- Unwinding area: steel wire is placed.

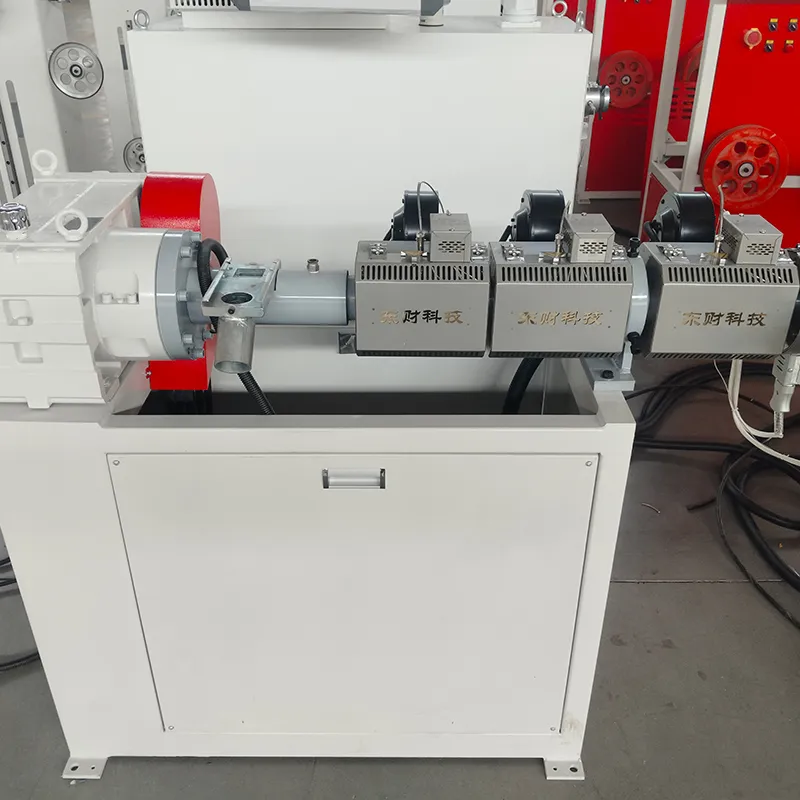

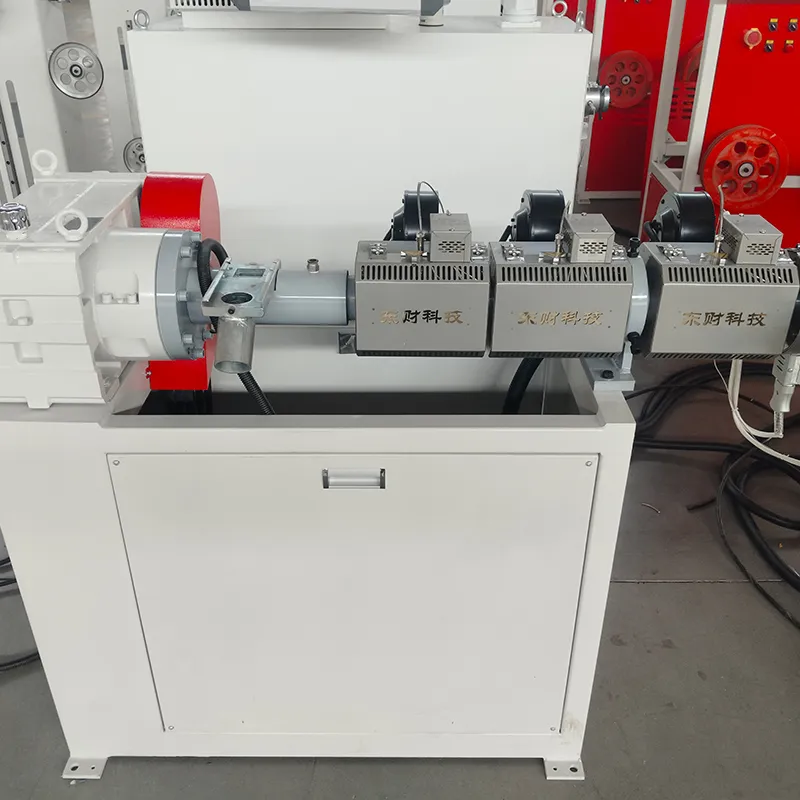

- Coating area: the plastic material is evenly coated on the surface of the substrate. This is usually achieved by extruder, spraying equipment or dipping equipment.

- Heating curing zone: heating the coated substrate to make the plastic material melt and closely adhere to the surface of the substrate. Heating methods may include hot air heating, infrared heating or electric heating.

- Cooling zone: cooling the substrate after heating and curing to ensure the curing effect and stability of plastic materials.

- Winding/cutting area: winding or cutting the cooled plastic products into required lengths and specifications.

- Quality inspection area: inspect the quality of plastic products, including appearance inspection, thickness measurement, adhesion test, etc., to ensure that the product quality meets the standards.

Second The Production Process

- Raw material preparation: prepare the required base materials and plastic materials, and ensure their quality meets the production requirements.

- Pretreatment: pretreat the substrate to improve its surface cleanliness and adhesion.

- Unwinding: Install the prepared steel wire to be plasticized to the unwinding equipment.

- Coating: the plastic material is evenly coated on the surface of the substrate to form a protective film.

- Heating curing: the coated substrate is heated to make the plastic material melt and closely adhere to the surface of the substrate.

- Cooling: cooling the substrate after heating and curing to ensure the curing effect and stability of plastic materials.

- Winding/cutting: According to the production requirements, the cooled plastic products are wound or cut into required lengths and specifications.

- Quality inspection: inspect the quality of plastic products to ensure that they meet the standards.

Write your message here and send it to us

Related News

Related products