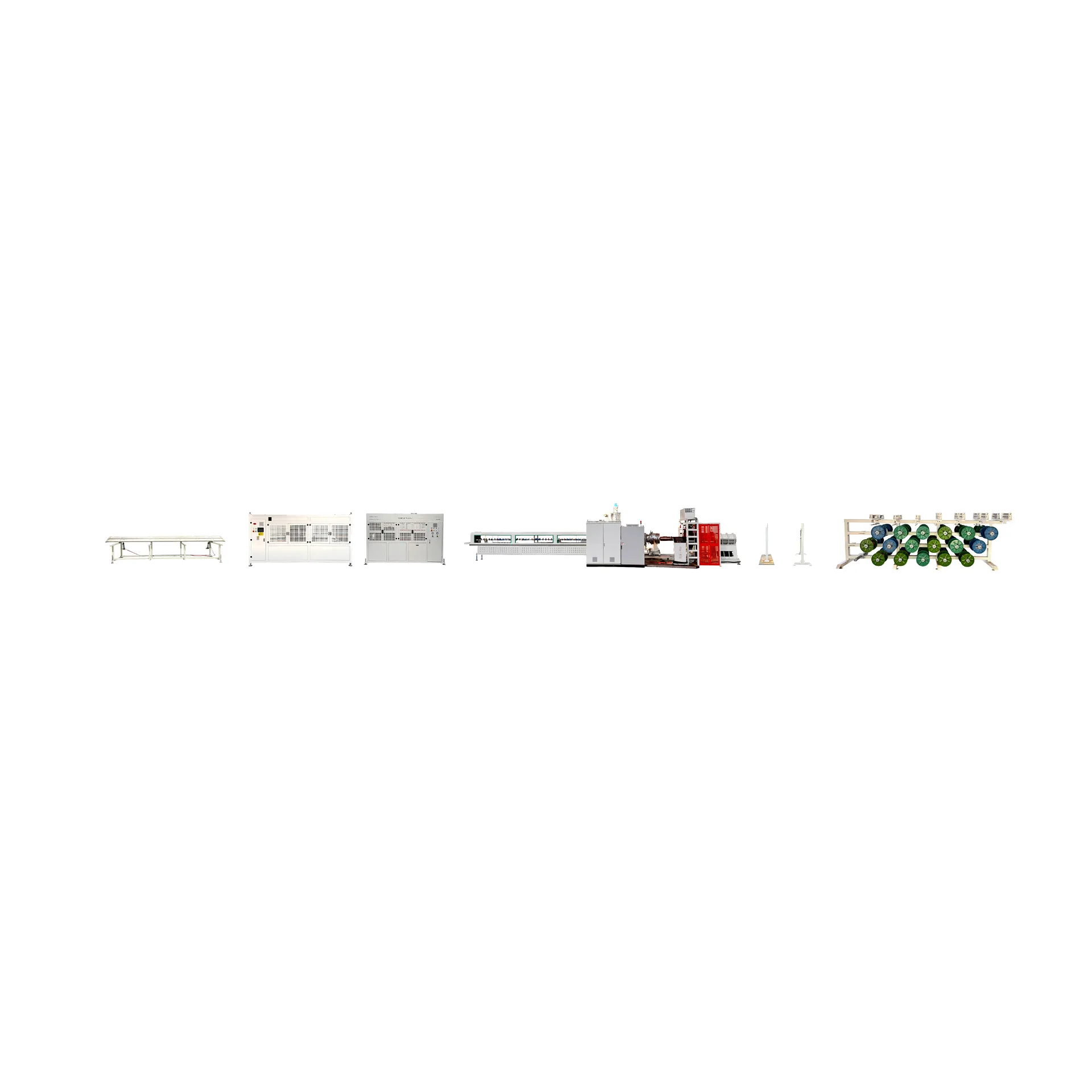

Short Description:

The whole production line is controlled by fully automatic PLC computer, with high degree of automation, high-efficiency and stable extruder, high-efficiency medium-frequency resistance welding device with servo motor for welding mesh forming machine, stable welding around 360 contacts on all sides, and all the precision parts of the mold are processed by its own processing base, which can ensure that the original materials of the mold are not fake and more accurate, and the 304 steel is used for bending and welding at one time, with an effective length box, frequency conversion 360 without dead angle cooling, and 2-12 frequency conversion tractors.

Highlight:

Highlight 1: The main engine adopts servo motor, international first-line brand electrical components and 40cr alloy structural steel screw, which is more durable.

Highlight 2: Liangdian second welding net forming machine is a new type of medium frequency resistance welding machine, which can control welding slag, surround 360 contacts on four sides and weld steel wire firmly, and can also ensure real-time detection in the welding process. The carbon brush is made of aviation graphite copper.

Highlight 3: The spray box is made of 304 stainless steel by one-time bending and welding, and the internal laser machine is integrated for cutting. The effective length is long, 360 has no dead angle cooling, and the cooling effect is very stable.