Driving Innovation: The Core of Overplastic Processing

The global imperative to manage plastic waste has driven significant innovation in recycling and reprocessing technologies. Central to this evolution is the development of robust and efficient machinery capable of transforming post-consumer and post-industrial plastic waste into valuable raw materials or finished products. Our over plastic Production Line stands at the forefront of this industrial transformation, offering a comprehensive solution for businesses aiming to enhance sustainability, reduce operational costs, and create new revenue streams from what was once considered waste. This advanced system integrates sophisticated engineering with practical application, providing a seamless workflow from material intake to final product output, addressing the critical demand for efficient resource utilization in today's manufacturing landscape.

The increasing focus on circular economy principles has accelerated demand for advanced recycling solutions. Industries are recognizing the long-term benefits of investing in technologies that not only process materials but also deliver high-quality outputs efficiently. The market for machinery facilitating the reprocessing of high-density polyethylene (HDPE), for instance, reflects this trend, with considerations like `hdpe machine price` now encompassing factors beyond initial cost, such as operational efficiency, output purity, and overall system longevity. Our approach to the `over plastic` Production Line is rooted in understanding these complex market dynamics, ensuring that our solutions offer superior performance and a compelling return on investment.

The Overplastic Production Line: A Detailed Process Workflow

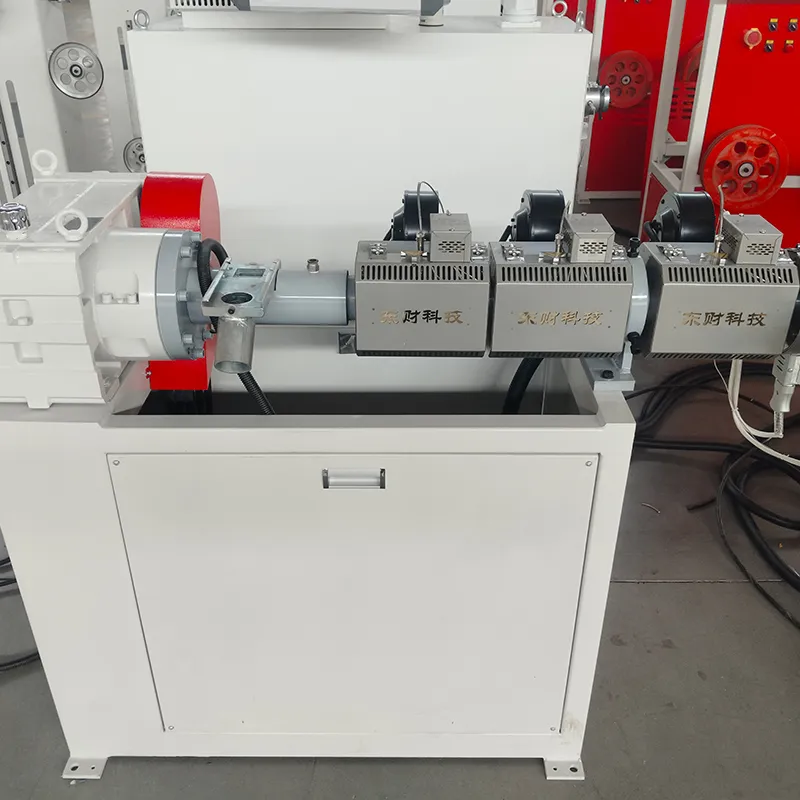

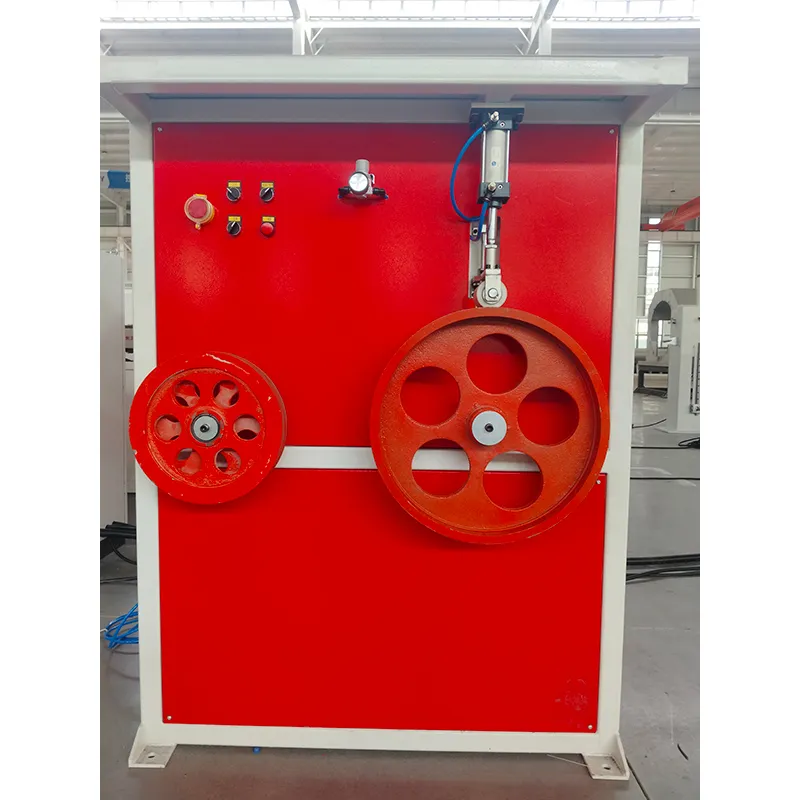

The manufacturing process within an over plastic production line is meticulously designed to handle various plastic types, transforming them through a series of integrated stages. This system typically begins with material pre-treatment, involving sorting, shredding, and washing to remove contaminants. Following this, the material undergoes a precise drying process, crucial for preventing degradation during subsequent thermal processing. The core of the line involves extrusion or molding, where the processed plastic is melted and reformed into new products or pellets. Precision engineering, including advanced CNC machining for critical components, ensures the consistent quality and dimensional accuracy of the machinery itself, which in turn guarantees high-quality output.

Product materials for the machinery components are selected for their durability and resistance to wear, such as high-grade alloy steels for extruders and specialized coatings for wear parts, ensuring an extended service life often exceeding 15 years under optimal operating conditions. Manufacturing processes like precision casting for structural integrity and hot forging for strength-critical parts are standard. Each component adheres to rigorous detection standards, including ISO 9001 for quality management and ANSI standards for specific mechanical tolerances. This stringent adherence ensures operational reliability and performance across diverse applications.

In typical application scenarios, such as in the petrochemical industry, the over plastic line can convert waste plastic into pipes or structural components resistant to chemical corrosion, demonstrating superior performance compared to traditional materials. For metallurgy, it provides robust, lightweight alternatives for non-load-bearing applications, while in water supply and drainage systems, the output includes highly durable, energy-efficient piping solutions that resist scaling and offer excellent flow characteristics. These advantages underscore the line's capability to deliver significant energy savings through reduced material processing energy and superior product performance attributes.

Key Technical Parameters and Performance Metrics

Understanding the technical specifications of an over plastic production line is crucial for assessing its suitability for specific industrial applications. Parameters such as throughput capacity, power consumption, and material compatibility directly impact operational efficiency and cost-effectiveness. Our production line is engineered for versatility, capable of processing a wide range of thermoplastic polymers, including HDPE, LDPE, PP, and PS, with minimal setup adjustments. This adaptability makes it an ideal investment for facilities dealing with varied plastic waste streams, maximizing the recovery and reuse of materials.

The following table outlines typical technical parameters, providing a clear insight into the capabilities of a modern over plastic system. These specifications are benchmarks for high performance and reliability, ensuring that the processed output meets stringent industry standards for subsequent manufacturing processes or direct product use.

| Parameter | Value Range | Unit |

|---|---|---|

| Throughput Capacity | 500 - 2000 | kg/hour |

| Total Installed Power | 150 - 450 | kW |

| Material Compatibility | HDPE, LDPE, PP, PS, ABS | N/A |

| Output Form | Pellets, Granules, Flakes, Finished Products | N/A |

| Water Consumption (Recycled) | 5 - 15 | m³/hour |

| Operating Noise Level | <85 | dB(A) |

| Dimensions (Typical) | 20x5x4 to 50x10x6 | meters (LxWxH) |

Technical Superiority and Operational Efficiency

The technical advantages of our over plastic production line are multifold, designed to deliver unparalleled operational efficiency and product quality. A key differentiator is the integration of advanced PLC (Programmable Logic Controller) systems, enabling precise control over every stage of the process—from feeding rates and extrusion temperatures to cooling and pelletization. This automation minimizes human error, optimizes energy consumption, and ensures consistent output, even with varying input materials. The robust construction, utilizing high-grade, corrosion-resistant stainless steel in critical sections, guarantees longevity and reduces maintenance requirements, proving to be a cost-effective solution over its extended service life.

Furthermore, our systems incorporate innovative energy recovery modules that capture and reuse heat generated during the extrusion process, significantly reducing overall power consumption. This commitment to energy efficiency not only lowers operating costs but also aligns with global sustainability goals. The modular design of the over plastic line allows for easy expansion or reconfiguration, adapting to future production demands or material types. This flexibility, coupled with high-precision engineering, ensures a reliable and high-performing solution for industrial plastic reprocessing.

Diverse Application Scenarios and Industry Impact

The versatility of the over plastic production line extends its application across a broad spectrum of industries, providing sustainable and economical solutions for material reprocessing. In the petrochemical sector, these lines are instrumental in converting refinery plastic waste into valuable feedstocks or finished products like industrial pipes and container111s, reducing environmental impact and enhancing resource recovery. For the metallurgical industry, recycled plastics can be transformed into protective coatings or lightweight structural components, offering corrosion resistance and reducing overall material weight in certain applications.

Beyond these, the over plastic line plays a crucial role in the construction sector, turning plastic waste into composite lumber, insulation, or paving materials, contributing to green building practices. In the context of water supply and drainage systems, the processed HDPE can be extruded into highly durable, long-lasting pipes that resist chemical degradation and biological growth, offering a superior alternative to traditional materials. This wide range of applications underscores the transformative potential of efficient plastic reprocessing, contributing significantly to circular economy initiatives and reducing dependence on virgin raw materials across various industrial landscapes.

Comparative Analysis: Overplastic Line vs. Market Alternatives

When evaluating investment in plastic reprocessing machinery, prospective buyers often compare offerings based on factors beyond just `hdpe machine price`. Total Cost of Ownership (TCO), technological sophistication, and after-sales support are paramount. Our over plastic production line distinguishes itself through a combination of high energy efficiency, exceptional output purity, and a robust design that minimizes downtime. While some cheaper alternatives may offer a lower initial `hdpe machine price`, they often come with higher operational costs due to inefficiency, frequent maintenance, and lower-quality output, ultimately leading to a higher TCO.

The following table provides a comparative overview, highlighting the key differentiators that make our Overplastic Production Line a superior choice for long-term industrial applications. This analysis focuses on aspects crucial for B2B decision-makers, emphasizing the value proposition beyond mere acquisition cost.

| Feature/Metric | Our Overplastic Production Line | Typical Competitor A | Typical Competitor B |

|---|---|---|---|

| Energy Efficiency (kWh/ton) | Optimized (180-220) | Average (250-300) | Moderate (220-270) |

| Output Purity (%) | >99.5 (Pellets) | ~98.0 | ~99.0 |

| Maintenance Frequency | Low | Moderate | Low-Moderate |

| Automation Level | High (Full PLC Control) | Partial | Advanced PLC Option |

| Customization Options | Extensive | Limited | Moderate |

| Warranty (Years) | 2 | 1 | 1.5 |

Custom Solutions and Unwavering Support

Recognizing that each industrial operation has unique requirements, we specialize in providing tailored solutions for our over plastic production lines. Our team of experienced engineers works closely with clients to understand their specific material input, desired output forms, and spatial constraints. This collaborative approach ensures that the final system is not just a standard product, but a highly optimized solution perfectly integrated into the client’s existing infrastructure and production goals. Whether it's adjusting throughput capacity, customizing feeding systems for particular waste types, or integrating specific post-processing units, our design capabilities are comprehensive.

Our commitment extends beyond initial setup. We provide extensive training for operational staff, ensuring they are fully proficient in managing and maintaining the over plastic system efficiently. This hands-on experience, coupled with our readily available technical support and comprehensive spare parts inventory, minimizes potential downtime and maximizes productivity. Our service cases consistently highlight our proactive approach to customer success, with dedicated specialists providing remote diagnostics and on-site assistance when required. This dedication to partnership ensures continuous, high-performance operation.

Real-World Impact: Exemplary Application Cases

Our over plastic Production Line has been successfully deployed in numerous demanding industrial environments globally, delivering tangible results in plastic waste reduction and resource recovery. For instance, a major automotive manufacturer implemented our system to process their in-house plastic scrap, primarily polypropylene (PP) and ABS, from their molding operations. The integrated line effectively processed over 8 tons of waste daily, converting it into high-quality pellets for reuse in non-critical components, significantly reducing their raw material procurement costs and landfill contributions. This case exemplifies the economic and environmental benefits derived from efficient in-house reprocessing.

Another notable application involved a large municipal recycling facility that integrated our solution to handle commingled HDPE waste from household collections. Faced with increasing volumes and stringent purity requirements, our line's advanced washing and separation capabilities ensured a clean, high-grade HDPE output, which was then sold to pipe manufacturers. This not only generated substantial revenue for the facility but also established a closed-loop system for their local plastic waste, demonstrating the profound impact of robust over plastic technology on regional sustainability initiatives. Customer feedback consistently highlights the reliability, ease of operation, and superior output quality of our systems.

Frequently Asked Questions (FAQ)

-

Q: What types of plastics can the Overplastic Production Line process?

A: Our line is designed to process a wide range of thermoplastics, including HDPE, LDPE, PP, PS, ABS, PVC, and PET. Specific configurations can be tailored to optimize processing for particular polymer types. -

Q: What is the typical installation and commissioning period?

A: Installation and commissioning typically range from 4 to 8 weeks, depending on the complexity and scale of the line. Our technical team provides on-site supervision and training to ensure a smooth startup. -

Q: What kind of after-sales support is provided?

A: We offer comprehensive after-sales support including remote diagnostics, regular maintenance checks, spare parts supply, and rapid-response on-site technical assistance to minimize any operational disruptions. -

Q: How does the Overplastic Production Line contribute to ROI?

A: The line contributes to ROI by reducing virgin material costs, minimizing waste disposal fees, creating new revenue streams from recycled products, and offering energy efficiency savings.

Our Commitment: Trust, Quality, and Partnership

We are committed to building lasting partnerships based on trust, quality, and mutual success. Our over plastic Production Line is backed by a robust quality assurance system, holding certifications such as ISO 9001:2015 for quality management and CE marking for European market compliance, affirming our adherence to international safety and performance standards. With over two decades of experience in delivering advanced industrial solutions, our track record speaks for itself, having served a diverse global clientele with complex reprocessing needs.

Our standard delivery cycle for a complete over plastic production line typically ranges from 90 to 150 days, depending on customization requirements and global supply chain conditions. Each line comes with a comprehensive 2-year warranty on major components and lifetime technical support, underscoring our confidence in the durability and reliability of our engineering. We believe in empowering our clients with not just machinery, but complete solutions that drive sustainable growth and operational excellence.

References

- Smith, J. (2022). "Advanced Polymer Recycling Technologies: Pathways to a Circular Economy." Journal of Sustainable Materials, Vol. 15, No. 3, pp. 112-128.

- European Plastics Converters. (2023). Plastic Recycling in Europe: Current State and Future Outlook. Brussels: EuPC Publications.

- Wang, L., & Zhang, P. (2021). "Energy Efficiency in Plastic Extrusion Processes: A Comprehensive Review." International Journal of Chemical Engineering, Vol. 2021, Article ID 8765432.

-

Innovative Solutions in PVC Pipe Production LineNewsJul.18,2025

-

Innovative Solutions in Pipe Extrusion Production LineNewsJul.18,2025

-

Advanced Plastic Profile Extrusion SolutionsNewsJul.18,2025

-

PVC Profiles: The Future of Durable and Cost-Effective Construction SolutionsNewsJun.06,2025

-

PVC Pipe Extrusion LineNewsJun.06,2025

-

High-Quality Polyethylene Pipe Production LineNewsJun.06,2025

-

High-Performance Tube Production LineNewsJun.06,2025