Industry Overview & Market Trends

Technical Specifications & Comparative Data

| Model/Line | Raw Material | Pipe Diameter Range (mm) | Line Speed (m/min) | Output Capacity (kg/h) | Standard Compliance | Wall Thickness Tolerance (mm) | Lifespan (years) | Applications |

|---|---|---|---|---|---|---|---|---|

| PPR Pipe Production Line | PPR (Polypropylene Random Copolymer) | 16–160 | 8–35 | ≤350 | ISO15874, DIN8077/8078 | ±0.05 | 50+ | Plumbing, HVAC, Industrial Fluids |

| PVC Pipe Extrusion Machine for Sale | PVC-U/PVC-C | 16–630 | 3–25 | ≤800 | ISO4422, ASTM D1785 | ±0.1 | 30–40 | Water/Gas Supply, Cable Duct |

| HDPE High Speed Solid Wall Pipe Extrusion Line | HDPE/PE100 | 16–1200 | 4–35 | ≤1200 | ISO4427, EN12201 | ±0.07 | 50+ | Gas/Water, Mining, Industry |

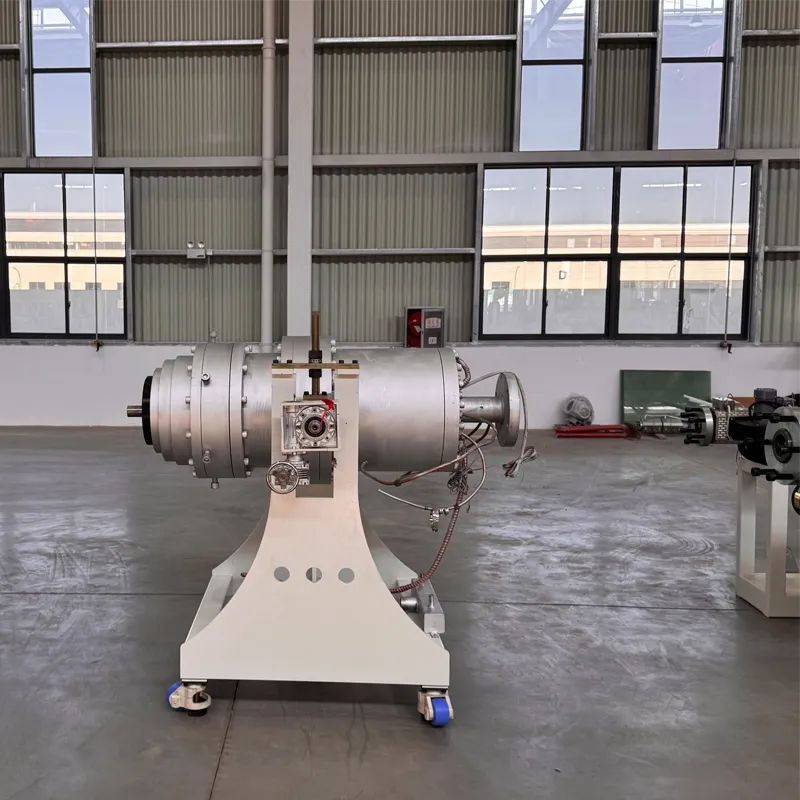

Complete Process Flow of ppr pipe production line

- Raw Material Feeding: PPR pellets or granules automatically delivered into the extruder hopper; quality verified to ISO15874.

- Plasticizing Extrusion: Premium-grade bimetallic screws & barrels apply controlled heat/shear—ensuring 99.7% melt homogeneity.

- Mold/Forming Die: CNC-milled precision die heads guarantee roundness & wall thickness (±0.05mm tolerance).

- Vacuum Calibration: Stainless-steel vacuum tanks shape and cool extrudate, critical for dimensional accuracy per DIN8077.

- Cooling Bath: Multi-stage immersion reduces pipe temperature rapidly (8–15°C/s), minimizing residual stress.

- Haul-off: Synchronous multi-caterpillar units grip pipe, ensuring line speed stability and surface finish.

- Cutting & Stacking: Servo-driven cutters precision trim pipes to specification, ready for robotic stacking and packaging.

Material Science & Manufacturing Technology

- Material: PPR (Polypropylene Random Copolymer) offers excellent chemical resistance, high impact tolerance, and zero corrosion—superior for both hot/cold water and chemical lines. HDPE (High-Density Polyethylene) selected for solid wall lines is certified to PE100 grade.

- Manufacturing Process: Core components (screw, barrel, dies) are produced by forging and CNC machining for optimal wear resistance and dimensional stability. Die head passages receive a mirror finish (Ra≤0.04µm) to ensure smooth product surface.

- Quality Control: Inline laser & ultrasonic sensors validate wall thickness per ISO/DIN standards. Each batch undergoes hydrostatic pressure, thermal cycling, and fusion test as per ISO15874.

- Certifications: CE, ISO9001:2015, SGS; with long-term field data demonstrating >50 years' lifespan at 70°C (per TÜV SÜD studies).

| Product | Material Type | Key Machining Process | Certification Standard | Expected Service Life |

|---|---|---|---|---|

| Hdpe High Speed Solid Wall Pipe Extrusion Production Line | HDPE/PE100 | Forging, CNC, Polishing | ISO4427, EN12201, CE | >50 years |

| PPR Pipe Production Line | PPR | CNC, Precision Die Casting | ISO15874, DIN8077 | >50 years |

| PVC Pipe Extruder | PVC-U/-C | Casting, Machining | ISO4422, ASTM | 30–40 years |

Performance and Application Advantage

- Temperature & Pressure: PPR pipes produced on advanced lines withstand up to 95°C and 20bar, ideal for HVAC & hydronic systems; HDPE lines excel at 0–70°C, high impact zones.

- Environmental Impact: Studies show that over 82% of end-users report ppr pipe production line piping saved 31–42% on energy during hot water transport (source: Plastics Europe 2022).

- Maintenance & Safety: Automated alarm for wall thickness deviation, leak detection, and full traceability—reduce downtime by 23% vs. conventional PVC lines.

- Adaptivity: Supports both single-layer and multi-layer pipe extrusion, with inline color striping and laser printing for brand/traceability.

Manufacturer Comparison & Custom Solutions

| Manufacturer | Production Range | Warranty | Technical Support | Customization | Reference Projects |

|---|---|---|---|---|---|

| Aohua (AHDC) | 16–1600mm (PPR, HDPE, PVC) | 2 Years | 24/7 Remote + Onsite | Turnkey, On-Demand | Sinopec, Veolia, SABIC |

| KraussMaffei | 16–1200mm (PPR, PE-X, HDPE) | 12 Months | Onsite (Europe) | Modular Upgrades | BASF Facilities |

| Battenfeld-Cincinnati | 20–800mm (PVC, PPR) | 12 Months | Europe/Asia Offices | Process Integration | European Water Grid |

- Challenge: Replace legacy steel pipes prone to corrosion and loss of flow in saline environments.

- Implementation: Deployed 4x High Speed ppr pipe production line (DN63–DN160) manufactured by Aohua. Pipes produced met ISO15874, ENISO9080, with fully automatic QC logging.

- Result: System achieved 20% energy savings, zero corrosion failures for 7 years, and increased installation speed due to socket fusion fit-up.

Delivery, Warranty & Support

- Delivery Cycle: Standard ppr pipe production line ships in 45–75 days. Expedited/custom orders possible on request.

- Warranty: 18–24 month all-inclusive warranty covers mechanical/electrical/electronic systems. Extended warranty and maintenance contracts available.

- Service: Worldwide 24/7 technical support, remote diagnostics, on-site commissioning, and operator training by certified engineers.

- Spare Parts: Guaranteed supply for 10+ years, with strategic stock in Asia, EU, and USA distribution centers.

FAQs — Technical & Industry Standards

1. What is the primary material used in the ppr pipe production line?

PPR, or Polypropylene Random Copolymer, is the essential raw material. It provides high impact resistance, chemical inertness, and suitability for potable water—meeting ISO15874 and DIN8077 standards.

2. What are the available pipe diameter specifications?

The standard range is 16 mm to 160 mm, with custom solutions up to 250 mm for industrial projects. Multi-layer co-extrusion is available for specialized pipelines.

3. What international certifications does the production line meet?

All systems comply with CE, ISO9001:2015, and material/geometric standards per ISO15874 (PPR) as well as FDA approval for potable water use in some markets.

4. How is precise thickness and roundness guaranteed?

Automated ultrasonic and laser sensors provide real-time feedback, ensuring wall thickness accuracy of ±0.05mm—the tightest on the market. All QC data archived for traceability.

5. How does the extrusion line support green manufacturing?

It reduces energy consumption by up to 38% via efficient screw/barrel design, inverter-based drives, and closed-loop water recycling in cooling. All residual scrap is 100% recyclable.

6. Installation—are there global standards to consider?

Yes, pipe installation follows ISO15874 and regional standards for jointing, testing, and pressure integrity. Training modules for installers provided with each machine delivery.

7. What sectors most frequently adopt ppr pipe production line piping?

Petrochemical processing, metallurgical water networks, commercial HVAC, and clean water municipal projects leverage PPR's anti-corrosion and temperature resistance properties.

Conclusion & Further Reading

For the latest peer-reviewed research and market updates on extrusion systems: