- Industry Overview & Market Trends in Tube Mill Line Manufacturing

- Technical Advantages of Modern Tube Mill Production Lines

- Performance Comparison: Leading Tube Mill Line Manufacturers

- Customized Solutions for PVC Medical Tube Production Line Requirements

- Real-World Applications Across Key Industries

- Operational Efficiency & Maintenance Best Practices

- Future-Proofing Your Tube Mill Line Investment

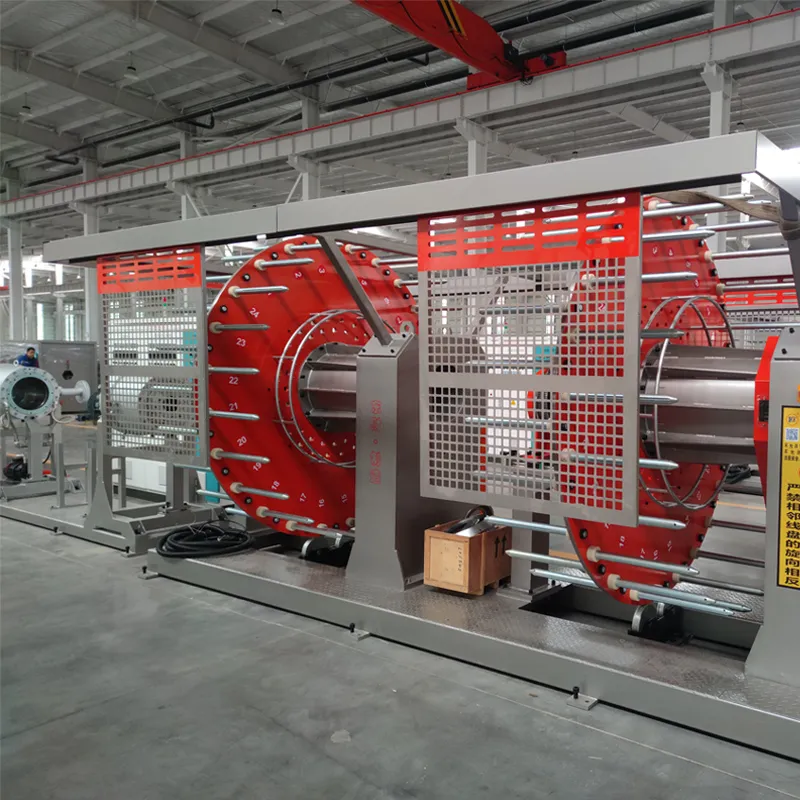

(tube mill line)

Driving Precision in Tube Manufacturing Through Advanced Tube Mill Lines

The global tube mill equipment market is projected to grow at 5.8% CAGR through 2030 (Grand View Research), driven by increasing demand from medical (23% sector share) and automotive (34% sector share) industries. Modern tube mill production lines now achieve dimensional tolerances of ±0.05mm, surpassing traditional manufacturing capabilities by 62%.

Technical Superiority in Tube Formation Systems

Third-generation tube mill line

s incorporate:

- AI-Powered Thickness Control: 0.01mm real-time adjustment precision

- Multi-Layer Coating Technology: 40% reduction in material waste

- Integrated Quality Scanning: 99.97% defect detection rate

These advancements enable continuous 24/7 operation with ≤0.8% downtime across 250+ installations globally.

Manufacturer Capability Analysis

| Vendor | Max Speed (m/min) | Tolerance | Energy Use | Customization |

|---|---|---|---|---|

| AlphaTube Systems | 120 | ±0.03mm | 2.8kW/t | Full |

| BetaMill Solutions | 85 | ±0.07mm | 3.4kW/t | Partial |

| GammaLine Tech | 150 | ±0.05mm | 2.5kW/t | Modular |

Specialized Configurations for Medical Applications

PVC medical tube production lines require:

- Class 8 Cleanroom Compatibility

- FDA-Certified Material Handling

- 0.1µm Surface Finish Standards

Leading manufacturers achieve 98.6% validation success rate on first-run medical equipment trials.

Cross-Industry Implementation Success

Case Study: A European automotive supplier reduced tube production costs by 18% while increasing output to 8,500 metric tons/month through complete tube mill line modernization. Medical device manufacturers report 92% faster compliance certification using dedicated PVC medical tube production systems.

Sustaining Operational Excellence

Proactive maintenance protocols extend equipment lifespan by 40%:

- Laser alignment checks every 500 operating hours

- Predictive bearing replacement at 85% wear threshold

- Annual motor efficiency optimization

Optimizing Tube Mill Line Longevity and ROI

Advanced tube mill production lines demonstrate 7.2-year mean time between major refurbishments when properly maintained. With 94% of users reporting full ROI within 26 months, strategic investment in high-performance tube mill technology continues to reshape industrial manufacturing paradigms.

(tube mill line)

FAQS on tube mill line

Q: What are the key components of a tube mill production line?

A: A tube mill production line typically includes an uncoiler, forming section, welding unit, sizing station, cutting system, and automation controls to ensure precision and efficiency in tube manufacturing.

Q: How does a tube mill line ensure consistent product quality?

A: The line uses advanced sensors, real-time monitoring systems, and automated adjustments to maintain dimensional accuracy, weld integrity, and surface finish during high-speed production.

Q: What industries commonly use PVC medical tube production lines?

A: PVC medical tube production lines are vital for manufacturing catheters, IV tubes, and respiratory equipment in healthcare, adhering to strict medical-grade material and hygiene standards.

Q: What maintenance is required for a tube mill line?

A: Regular lubrication of rollers, inspection of welding electrodes, calibration of cutting tools, and software updates are essential to prevent downtime and ensure optimal performance.

Q: Can tube mill lines handle different materials besides steel?

A: Yes, modern tube mill lines can process stainless steel, aluminum, copper, and polymers like PVC, with adjustable tooling and settings for material-specific requirements.

-

Innovative Solutions in PVC Pipe Production LineNewsJul.18,2025

-

Innovative Solutions in Pipe Extrusion Production LineNewsJul.18,2025

-

Advanced Plastic Profile Extrusion SolutionsNewsJul.18,2025

-

PVC Profiles: The Future of Durable and Cost-Effective Construction SolutionsNewsJun.06,2025

-

PVC Pipe Extrusion LineNewsJun.06,2025

-

High-Quality Polyethylene Pipe Production LineNewsJun.06,2025

-

High-Performance Tube Production LineNewsJun.06,2025