In an era defined by rapid urbanization and the continuous upgrading of infrastructure, the demand for high-performance piping solutions has never been greater. At the heart of meeting this demand lies advanced manufacturing technology, specifically the ppr pipe production line. This specialized equipment is crucial for producing pipes that are essential across various sectors, from residential plumbing to large-scale industrial fluid transport. While our focus today is primarily on the robust capabilities of a ppr pipe production line, it's important to acknowledge the broader context of plastic pipe manufacturing, including the versatility offered by a pvc pipe extrusion machine for sale and the robust performance of a pvc extruder machine for sale in their respective applications. The precision, efficiency, and durability delivered by these production lines directly impact the longevity and reliability of critical infrastructure worldwide.

Global Trends and Market Dynamics in Plastic Pipe Manufacturing

The global plastic pipe market is experiencing robust growth, driven by increasing investments in water and wastewater infrastructure, expanding construction activities, and the replacement of aging conventional pipe systems. According to recent industry reports, the global plastic pipes and fittings market size was valued at approximately USD 200 billion in 2023 and is projected to reach over USD 300 billion by 2032, exhibiting a compound annual growth rate (CAGR) of 4.5% from 2024 to 2032. This growth is largely fueled by the superior properties of plastic pipes, such as corrosion resistance, light weight, ease of installation, and cost-effectiveness, compared to traditional materials like metal or concrete.

The ppr pipe production line plays a pivotal role in this expansion, particularly in hot and cold water supply systems within buildings due to PPR's excellent heat resistance and hygienic properties. Simultaneously, the market for PVC pipes, produced by a high-efficiency pvc pipe extrusion machine for sale or a dedicated pvc extruder machine for sale, remains significant for drainage, sewage, and industrial applications, owing to PVC's rigidity, chemical resistance, and affordability. The industry trend is towards higher efficiency, greater automation, and enhanced material versatility, pushing manufacturers to invest in advanced production lines that can meet stringent quality standards and diverse application requirements. This technological evolution aims to minimize waste, optimize energy consumption, and increase output, thereby enhancing the profitability and sustainability of pipe manufacturing operations.

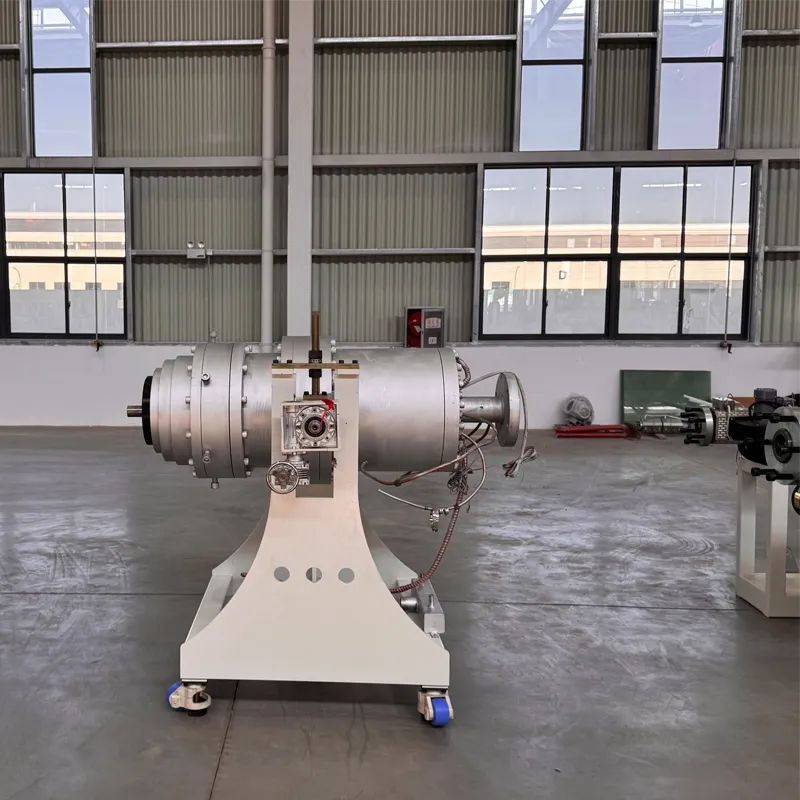

Introducing the Hdpe High Speed Solid Wall Pipe Extrusion Production Line

Our featured product, the Hdpe High Speed Solid Wall Pipe Extrusion Production Line, exemplifies the pinnacle of modern pipe manufacturing technology. While optimized for HDPE, its foundational principles and advanced engineering are directly applicable to understanding high-speed ppr pipe production line systems. This line is engineered for producing high-quality solid wall pipes with exceptional speed and precision, designed to meet the rigorous demands of various industries.

Core Technical Parameters and Product Specifications

The performance of any pipe extrusion line is fundamentally defined by its technical parameters. The Hdpe High Speed Solid Wall Pipe Extrusion Production Line boasts state-of-the-art components optimized for maximum throughput and product quality. Key specifications include:

| Parameter | Typical Specification (High-Speed PPR/HDPE Line) | Significance for Production |

|---|---|---|

| Extruder Type | Single Screw Extruder (e.g., SJ-series, high efficiency) | Optimized for polymer melting and homogenization, ensuring consistent output. |

| Screw Diameter | 65mm - 120mm | Larger diameter typically means higher output capacity. |

| L/D Ratio (Length/Diameter) | 36:1 to 40:1 | Higher ratio allows for better plasticization and melt homogeneity, crucial for pipe quality. |

| Main Motor Power | 55kW - 160kW | Indicates power and capacity for continuous, high-speed operation. |

| Output Capacity | 200 kg/h - 1200 kg/h (material dependent) | Directly impacts production volume and overall efficiency. |

| Pipe Diameter Range | DN16mm - DN630mm (or larger for specific models) | Determines the versatility and range of pipes that can be produced. |

| Line Speed | 15 m/min - 60 m/min (for smaller diameters) | High speed is a hallmark of efficient modern extrusion lines. |

| Control System | PLC (Programmable Logic Controller) with HMI (Human Machine Interface) | Enables precise control, automation, and real-time monitoring of the entire process. |

Detailed Manufacturing Process of a PPR Pipe Production Line

The manufacturing process on a ppr pipe production line is a complex, synchronized dance of machinery and material science, ensuring the production of high-quality, consistent pipes. While we detail the general steps, the Hdpe High Speed Solid Wall Pipe Extrusion Production Line follows very similar principles for its designated material.

1. Material Feeding and Drying: The process begins with raw PPR (Polypropylene Random Copolymer) granules. These granules are typically conveyed from a storage silo to a hopper, which feeds directly into the extruder. Before entering, some systems incorporate a drying unit to remove any moisture from the resin, which is critical for preventing defects like voids or bubbles in the final pipe. The moisture content must be precisely controlled, often to less than 0.05%.

2. Extrusion: The heart of the ppr pipe production line is the single-screw extruder. The raw PPR granules are fed into the extruder barrel, which contains a rotating screw. As the screw rotates, it conveys, compresses, melts, and homogenizes the plastic material through a combination of mechanical shear and heating elements surrounding the barrel. The temperature profile along the barrel is carefully controlled (e.g., 180°C to 230°C for PPR) to ensure complete melting without degradation, achieving a uniform molten polymer.

3. Die Head and Forming: The molten plastic, now a viscous, homogeneous melt, is pushed through a specially designed die head. The die head shapes the molten plastic into a continuous tubular form with the desired outer diameter (OD) and wall thickness (WT). Precision-engineered die heads, often manufactured using advanced CNC machining processes, are crucial here to ensure exact pipe dimensions and concentricity. The design of the spiral flow channels or spider die within the die head ensures a smooth, even flow of melt without weld lines.

4. Vacuum Calibration Tank: Immediately after exiting the die head, the hot, pliable pipe enters the vacuum calibration tank. This unit is critical for sizing the pipe accurately and maintaining its roundness. A vacuum pump creates a controlled negative pressure inside the tank, pulling the molten pipe against the sizing sleeve (calibration sleeve), which precisely shapes the outer diameter. Simultaneously, water sprays within the tank begin the initial cooling process, allowing the pipe to solidify enough to hold its dimensions. This step is vital for meeting strict dimensional tolerances (e.g., ISO 15874 for PPR pipes specifies OD tolerances).

5. Cooling Tanks: Following the vacuum calibration, the pipe passes through one or more long cooling tanks, typically filled with circulating water. This extensive cooling ensures that the pipe fully solidifies and its molecular structure stabilizes. The length of the cooling section depends on the pipe diameter and line speed; larger pipes or faster lines require longer cooling to prevent deformation after cutting. Water temperature is also precisely controlled to optimize cooling efficiency without inducing internal stresses.

6. Haul-off Unit: A multi-caterpillar haul-off unit pulls the pipe steadily and continuously through the entire line (extruder, die, vacuum, cooling tanks). The haul-off speed is precisely synchronized with the extruder output rate and screw speed to maintain consistent wall thickness and diameter. The number of caterpillars (usually 2 to 8) depends on the pipe diameter and required pulling force, ensuring stable traction without deforming the pipe.

7. Cutting Unit: Once the pipe has fully cooled and solidified, it reaches the cutting unit. For smaller diameter pipes, a high-speed non-chip cutter or planetary saw is often used to make precise, burr-free cuts to the pre-set length. For larger diameters, a specialized saw cutter might be employed. The cutting mechanism is synchronized with the haul-off speed to ensure accurate cut lengths, often controlled by an encoder for precise measurement.

8. Stacking or Winding: Finally, the cut pipes are either automatically stacked onto a collection table (for larger, rigid pipes) or wound onto a coiler (for smaller, flexible pipes like those used in heating systems). The winder or stacker is typically equipped with an automatic traversing mechanism to ensure neat coiling or stacking.

Throughout this entire process, advanced sensors and a PLC (Programmable Logic Controller) based control system monitor and adjust parameters such as temperature, pressure, speed, and dimensions in real-time, ensuring optimal performance and consistent product quality. The integration of precision manufacturing techniques, such as CNC machining for critical components like die heads, ensures that each part of the production line contributes to the overall accuracy and efficiency of pipe manufacturing.

Product Material, Manufacturing, and Standards

The pipes produced by this line, specifically HDPE pipes, are renowned for their exceptional physical and chemical properties. High-Density Polyethylene (HDPE) offers superior resistance to corrosion, abrasion, and chemical attack, making it ideal for harsh environments. When discussing a ppr pipe production line, the material is Polypropylene Random Copolymer (PPR), known for its high temperature resistance (up to 95°C for continuous operation), excellent chemical inertness, and smooth interior surface that prevents scale buildup and ensures low friction losses. Both materials boast a service life often exceeding 50 years under proper installation and operating conditions, far outperforming many traditional pipe materials.

The manufacturing process for the components of the production line itself is rigorously controlled. Critical parts like screws and barrels are made from high-grade alloy steel, heat-treated for optimal hardness and wear resistance. Die heads and sizing sleeves are often forged or precisely cast from special steels and then finished with high-precision CNC machining to ensure micron-level accuracy, which is paramount for dimensional consistency of the final pipe. All manufacturing adheres to international standards, including ISO 9001 for quality management systems and specific product standards like ISO 4427 for HDPE pipes and ISO 15874 for PPR pipes. Furthermore, components often carry CE certification, guaranteeing compliance with European safety, health, and environmental protection requirements. This meticulous attention to detail in manufacturing ensures that the output pipes meet or exceed standards set by organizations like ANSI (American National Standards Institute) or ASTM (American Society for Testing and Materials) for various applications.

Technical Advantages and Innovative Edge

The Hdpe High Speed Solid Wall Pipe Extrusion Production Line, and by extension, advanced ppr pipe production line systems, offer significant technical advantages that translate directly into operational benefits and superior product quality:

- High-Speed Efficiency: Leveraging optimized screw designs, efficient heating systems, and advanced cooling technologies, these lines can achieve remarkable production speeds, significantly increasing throughput and reducing per-unit costs. For instance, smaller diameter PPR pipes can be produced at speeds up to 60 meters per minute.

- Exceptional Precision and Stability: Equipped with sophisticated PLC control systems, gravimetric dosing units, and online ultrasonic thickness gauges, these lines offer unparalleled control over pipe dimensions, ensuring consistent wall thickness, ovality, and outer diameter within tight tolerances. This precision minimizes material waste and ensures product conformity to international standards.

- Energy Optimization: Modern extruders incorporate energy-efficient motors (e.g., IE3/IE4 standard) and intelligent temperature control zones, which significantly reduce power consumption. Vacuum pumps and cooling systems are also designed for efficiency, contributing to lower operational costs and a reduced carbon footprint.

- Versatility in Application: While this specific line targets HDPE, the underlying technology allows for adaptability. A well-designed ppr pipe production line can be configured to produce pipes of various pressure ratings (PN10, PN12.5, PN16, PN20) and diameters, serving diverse applications from domestic hot water to industrial fluid transport.

- Enhanced Product Lifespan: The controlled manufacturing environment and precise material handling contribute to the production of pipes with superior physical properties, leading to an extended service life often exceeding 50 years, significantly reducing maintenance and replacement costs over time.

- Corrosion and Chemical Resistance: Both HDPE and PPR pipes are inherently resistant to corrosion, rust, and chemical degradation, making them ideal for transporting a wide range of fluids, including acids, alkalis, and potable water, without compromising purity or structural integrity.

Diverse Application Scenarios and Industry Impact

Pipes produced by a ppr pipe production line are ubiquitous across numerous critical sectors, demonstrating their versatility and indispensable nature. The impact of high-quality plastic pipes on infrastructure development and daily life cannot be overstated.

- Residential and Commercial Buildings: PPR pipes are the preferred choice for hot and cold water supply systems in homes, apartments, hotels, and office buildings due to their heat resistance, anti-corrosion properties, and hygienic nature. They ensure clean water delivery and are easy to install.

- Municipal Water Supply and Drainage: HDPE pipes, produced by lines similar to our highlighted product, are widely used in large-scale municipal potable water distribution networks and sewerage systems. Their flexibility allows for trenchless installation (horizontal directional drilling), minimizing disruption and costs. For drainage, PVC pipes (from a pvc pipe extrusion machine for sale) remain a cost-effective and reliable option.

- Petrochemical and Chemical Industries: Both HDPE and PPR pipes are crucial for transporting various corrosive chemicals, industrial wastewater, and slurries in chemical plants, oil refineries, and mining operations. Their chemical inertness ensures safety and prevents pipe degradation, significantly reducing maintenance costs and risks compared to metal alternatives.

- Agricultural Irrigation: In agriculture, large diameter HDPE and PVC pipes are extensively used for efficient water distribution in irrigation systems, helping conserve water resources and boost crop yields. The durability and resistance to UV radiation make them suitable for outdoor applications.

- Gas Distribution: HDPE pipes are globally recognized as the standard for natural gas distribution networks due to their leak-free fused joints, resistance to external loads, and long service life, ensuring safe and reliable gas delivery.

- Specialized Applications: This includes applications in geothermal heating and cooling systems (PPR), industrial cooling water systems, and even in some food processing facilities where hygienic fluid transport is critical.

The ability of these production lines to deliver pipes that are not only durable and reliable but also offer benefits like energy saving (due to smooth inner walls reducing pumping costs) and superior corrosion resistance, positions them as key enablers for sustainable development across global industries.

Manufacturer Comparison and Selection Criteria

Choosing the right ppr pipe production line or a pvc extruder machine for sale is a critical decision that impacts long-term operational efficiency, product quality, and profitability. The market offers a range of manufacturers, and discerning buyers should look beyond initial price to consider several key factors:

- Research & Development (R&D) Capabilities: Leading manufacturers continuously invest in R&D to innovate and improve their extrusion technology. This includes developing more efficient screw designs, advanced die heads, and integrated control systems that offer higher speeds, lower energy consumption, and greater precision.

- Manufacturing Precision and Quality Control: A reputable manufacturer will employ advanced manufacturing techniques (e.g., CNC machining for critical components, stringent quality checks at every stage) to ensure the durability and performance of their machinery. Look for certifications like ISO 9001.

- After-Sales Service and Technical Support: This is paramount. Does the manufacturer offer comprehensive installation support, operator training, readily available spare parts, and responsive technical assistance (both remote and on-site)? A strong after-sales network ensures minimal downtime.

- Customization Options: Can the production line be tailored to specific requirements, such as unique pipe diameters, different materials (e.g., capability to switch between PPR, HDPE, or PVC with minimal modifications), higher automation levels, or integration with existing factory layouts?

- Track Record and Industry Reputation: Investigate the manufacturer's history, customer testimonials, and successful installations worldwide. A long-standing presence and positive client feedback are strong indicators of reliability and trustworthiness.

- Energy Efficiency and Automation Level: Compare energy consumption data (kW/kg of output) and the level of automation (e.g., automatic dosing, online measurement, integrated cutting and coiling) to assess long-term operational costs and labor efficiency.

For instance, while a budget-friendly pvc extruder machine for sale might seem appealing, a slightly higher investment in a machine from a reputable manufacturer with proven technology often results in superior pipe quality, higher operational uptime, and lower lifetime costs due to reduced maintenance and energy consumption. This difference becomes even more pronounced for high-speed lines like the Hdpe High Speed Solid Wall Pipe Extrusion Production Line, where precision and stability directly translate to profitability.

Customized Solutions and Engineering Expertise

Recognizing that no two production facilities are identical, leading suppliers of ppr pipe production line and similar extrusion systems excel in offering highly customized solutions. Our approach focuses on delivering tailored engineering services that perfectly align with client-specific needs and operational objectives.

- Capacity Matching: Whether a client requires a line for small-batch specialized pipe production or a high-volume setup capable of producing tons of pipe per hour, solutions are scalable. This involves selecting the appropriate extruder size, number of cooling tanks, and haul-off capacity.

- Material Versatility: While a line might be designed primarily for PPR or HDPE, modifications can be made to handle other thermoplastics. This could involve different screw designs, heating profiles, or specialized die heads.

- Automation Integration: From fully automated raw material feeding systems (gravimetric dosing for precise material blend) to robotic stacking and packaging units at the end of the line, the level of automation can be customized to minimize labor costs and improve consistency.

- Factory Layout Optimization: Our engineering teams work closely with clients to design a ppr pipe production line that integrates seamlessly into existing factory spaces, optimizing workflow and material handling. This includes considerations for space, utilities, and material flow from raw material to finished product storage.

- Specialty Pipe Production: Customization extends to producing pipes with specific features, such as multi-layer pipes (e.g., PPR with fiberglass reinforcement), corrugated pipes, or pipes with integrated heating elements, requiring specialized co-extrusion technology.

This deep dive into customization ensures that businesses receive not just a machine, but a complete, optimized manufacturing solution that addresses their unique production challenges and market demands, maximizing efficiency and return on investment.

Application Cases and Customer Success Stories

The real-world impact of a reliable ppr pipe production line is best illustrated through its application in diverse projects. Our experience spans various industries, providing critical infrastructure solutions globally, reflecting the expertise and experience we bring to the table.

Case Study 1: Large-Scale Municipal Water Infrastructure Project in Southeast Asia

A major municipal authority in Southeast Asia undertook an ambitious project to upgrade its aging water supply network. The requirement was for several hundred kilometers of durable, corrosion-resistant HDPE pipes, ranging from DN110mm to DN315mm, with a projected service life of 50 years. We supplied a high-speed Hdpe High Speed Solid Wall Pipe Extrusion Production Line capable of producing these large-diameter pipes with consistent quality and high output. The line's advanced PLC control system ensured precise dimensional accuracy, minimizing material waste. Our on-site installation and training team ensured a smooth setup and rapid operational readiness. The project was completed ahead of schedule, with the client reporting a significant reduction in system leakage rates compared to the previous infrastructure, leading to substantial water conservation and reduced operational costs.

Case Study 2: Chemical Fluid Transport System for a European Industrial Plant

An industrial chemical manufacturing plant in Europe required a reliable solution for transporting various corrosive fluids within its facility. They needed a ppr pipe production line capable of manufacturing PN20 rated PPR pipes with excellent chemical resistance and high-temperature tolerance. Our customized solution included a specialized extruder with enhanced corrosion-resistant components and a precision die head to produce pipes from DN50mm to DN160mm. The smooth internal surface of the PPR pipes prevented chemical residue buildup, and the system’s robust design ensured a safe and leak-free transport network. The client noted a drastic reduction in maintenance expenditures and improved operational safety, attributing it to the superior quality and durability of the PPR pipes produced by our line.

Case Study 3: Cost-Effective Irrigation Solutions in Sub-Saharan Africa

A consortium of agricultural development organizations in Sub-Saharan Africa sought an efficient and cost-effective method to produce PVC pipes for large-scale irrigation projects. They required a pvc extruder machine for sale that was robust, easy to operate, and capable of handling varying raw material qualities. We provided a highly reliable pvc extruder machine for sale optimized for local conditions, focusing on energy efficiency and ease of maintenance. The machine produced high volumes of PVC pipes (DN63mm to DN250mm) that were durable and ideal for agricultural applications, including resistance to UV degradation. This enabled the rapid deployment of irrigation systems, leading to improved water management, increased crop yields, and enhanced food security in the region.

These cases exemplify how our advanced production lines, whether for PPR, HDPE, or PVC, provide not just machinery, but comprehensive solutions that deliver tangible benefits, including improved efficiency, reduced operational costs, and enhanced project reliability. Our commitment to client success and long-term partnerships is a cornerstone of our service philosophy.

Our Commitment to Quality and Trustworthiness

At the core of our operations is an unwavering commitment to quality and building lasting trust with our clients. This commitment is reflected in every aspect of our manufacturing process, product design, and customer support for our Hdpe High Speed Solid Wall Pipe Extrusion Production Line and related systems.

Industry Certifications and Standards

Our manufacturing facilities operate under stringent quality management systems. We are ISO 9001 certified, ensuring that every stage, from design and material procurement to production, assembly, and testing, adheres to the highest international quality standards. Furthermore, our products, including the ppr pipe production line and pvc pipe extrusion machine for sale, are CE certified, confirming compliance with the health, safety, and environmental protection requirements of the European Union. We also ensure that the pipes produced by our lines meet relevant international product standards such as ISO 4427 (for HDPE), ISO 15874 (for PPR), and various ASTM/DIN standards, which is a testament to the consistency and reliability of the output.

Strategic Partnerships and Authoritative Citations

We believe in collaboration to drive innovation. Our company maintains strategic partnerships with leading raw material suppliers, research institutions, and technology providers. This ensures we integrate the latest material science advancements and engineering breakthroughs into our ppr pipe production line designs. We actively participate in industry forums and regularly cite authoritative sources and academic research in polymer processing to ensure our practices are at the forefront of the industry. For example, our screw designs often reference established theories from plastic extrusion engineering journals to optimize melt homogenization and throughput.

Comprehensive Warranty and After-Sales Support

We stand by the quality and durability of our equipment. The Hdpe High Speed Solid Wall Pipe Extrusion Production Line comes with a standard warranty, typically covering critical components for a specified period (e.g., 12-24 months from installation). Our commitment extends beyond the sale, offering comprehensive after-sales support:

- Installation & Commissioning: Our experienced engineers provide on-site installation, commissioning, and optimization services to ensure the line is set up correctly and running at peak performance.

- Operator Training: We conduct thorough training programs for our clients' technical teams, covering operation, routine maintenance, troubleshooting, and safety protocols, empowering them to manage the production line efficiently.

- Spare Parts Availability: A readily available inventory of genuine spare parts ensures minimal downtime. We offer fast delivery services globally to keep your operations running smoothly.

- Technical Assistance: Our dedicated technical support team is available via phone, email, or remote diagnostics to assist with any operational queries or troubleshooting needs, often resolving issues within hours. For complex problems, on-site service can be dispatched.

Transparent Delivery Cycle

The delivery cycle for a new ppr pipe production line or pvc extruder machine for sale typically ranges from 60 to 120 working days, depending on the level of customization and the specific configuration required. This timeline includes design, manufacturing, quality control, and pre-shipment testing. We provide detailed project timelines and maintain transparent communication with our clients throughout the entire process, ensuring they are informed at every stage from order confirmation to final delivery.

This comprehensive approach to quality, partnerships, support, and transparency solidifies our position as a trustworthy and authoritative provider of advanced plastic pipe extrusion solutions.

Professional FAQ: In-Depth Insights into Pipe Production Lines

To further enhance understanding and address common inquiries, here are answers to frequently asked professional questions about the ppr pipe production line and related extrusion technologies:

1. What is the typical lifespan of pipes produced by a high-quality ppr pipe production line?

Pipes produced by a well-maintained ppr pipe production line using high-quality raw materials can have a service life exceeding 50 years under normal operating conditions, especially when installed correctly and used within their specified temperature and pressure ratings (e.g., PN20 pipes are designed for 20 bar pressure at 20°C). This longevity is due to PPR's excellent resistance to corrosion, scaling, and high temperatures, along with the precise manufacturing process that ensures consistent wall thickness and material homogeneity.

2. What are the key differences between a ppr pipe production line and a pvc pipe extrusion machine for sale?

The primary differences lie in the raw material processed and the specific applications of the finished pipes. A ppr pipe production line processes Polypropylene Random Copolymer, yielding pipes ideal for hot and cold water supply due to their heat resistance and flexibility. A pvc pipe extrusion machine for sale, on the other hand, processes Polyvinyl Chloride (PVC), producing pipes typically used for drainage, sewage, and unpressurized applications, valued for their rigidity, chemical resistance, and cost-effectiveness. While the core extrusion principles are similar, the extruder screw design, heating zones, and die head configurations are optimized for the specific rheological properties of PPR versus PVC.

3. How does the Hdpe High Speed Solid Wall Pipe Extrusion Production Line ensure energy efficiency?

The Hdpe High Speed Solid Wall Pipe Extrusion Production Line incorporates several features for energy efficiency. This includes high-efficiency main motors (e.g., IE3 or IE4 standards) that minimize power loss, optimized screw geometries that reduce energy required for melting and plasticizing, and intelligent temperature control systems that prevent overheating and maintain stable processing temperatures. Additionally, efficient vacuum pumps and cooling systems reduce overall energy consumption, leading to significant operational cost savings.

4. What kind of raw materials can be processed on this line, and how does it handle material variation?

While the Hdpe High Speed Solid Wall Pipe Extrusion Production Line is specifically designed for High-Density Polyethylene, similar high-speed lines can be adapted for PPR, PP-B, or other polyolefin materials. The line is designed to handle standard granular forms of these polymers. To manage material variation, advanced lines often include gravimetric dosing systems that precisely weigh and blend virgin material with masterbatch and regrind, ensuring consistent material composition and stable output quality, even if there are slight variations in the bulk density of the incoming raw material.

5. What are the critical inspection standards for the finished pipes produced by these lines?

Finished pipes must adhere to various international and national standards. For PPR pipes, ISO 15874 (Plastics piping systems for hot and cold water installations – Polypropylene (PP)) is common, specifying dimensions, mechanical properties, and long-term performance. For HDPE, ISO 4427 (Polyethylene (PE) pipes for water supply – Specifications) and ASTM F714 are key. Critical inspections include measuring outer diameter (OD), wall thickness (WT), ovality, impact resistance, hydrostatic pressure testing, melt flow rate (MFR) of the material, and assessment for surface defects. Many lines integrate online ultrasonic thickness gauges for real-time monitoring and control, ensuring continuous compliance.

6. Can the ppr pipe production line be customized for specific pipe diameters or production capacities?

Absolutely. Customization is a key offering. A ppr pipe production line can be scaled for various pipe diameters (e.g., from DN16mm to DN160mm, or larger for specialized lines) by changing the die head and sizing sleeve. Production capacity can be adjusted by selecting an extruder with a suitable output (kg/h), optimizing the L/D ratio of the screw, and configuring the number and length of cooling tanks and the haul-off speed. Manufacturers work closely with clients to design a line that meets their specific market demands and production goals.

7. What kind of after-sales support and spare parts are available for these sophisticated production lines?

Comprehensive after-sales support is crucial for complex machinery. Reputable manufacturers provide services including on-site installation and commissioning, operator training, remote technical assistance (via phone, email, or even VPN for PLC diagnostics), and prompt supply of genuine spare parts. Critical spare parts, such as heating elements, thermocouples, pressure sensors, and specialized seals, are usually kept in stock for immediate dispatch to minimize downtime. For major components like screws and barrels, replacement strategies are planned in advance based on wear and tear over time.

8. How does CNC machining contribute to the precision of the die head in a ppr pipe production line?

CNC (Computer Numerical Control) machining is fundamental to achieving the extreme precision required for die heads in a ppr pipe production line. Die heads, often complex multi-channel flow devices, determine the exact dimensions (OD and WT) and concentricity of the pipe. CNC machining allows for the creation of intricate, smooth internal flow channels with micron-level tolerances, ensuring uniform melt distribution and eliminating flow imbalances that could lead to uneven wall thickness or internal stresses in the pipe. This precision is vital for producing high-quality pipes that meet stringent industry standards and have a long service life.

Conclusion

The modern ppr pipe production line, alongside its counterparts like the Hdpe High Speed Solid Wall Pipe Extrusion Production Line and the versatile pvc extruder machine for sale, stands as a testament to advanced engineering and material science. These sophisticated systems are not merely machines; they are the bedrock of global infrastructure, delivering essential fluid transport solutions across residential, industrial, and agricultural sectors. The ongoing advancements in efficiency, precision, and automation ensure that the plastic pipe industry continues to meet the evolving demands of a growing world, offering durable, cost-effective, and environmentally conscious solutions. Investing in a high-quality production line is an investment in long-term reliability, operational excellence, and sustainable development.

For further reading and in-depth technical discussions on plastic pipe extrusion, we recommend exploring industry resources and academic journals:

- Plastics Pipe Institute (PPI): https://plasticpipe.org/

- Journal of Applied Polymer Science: https://onlinelibrary.wiley.com/journal/10974628

-

Innovative Solutions in PVC Pipe Production LineNewsJul.18,2025

-

Innovative Solutions in Pipe Extrusion Production LineNewsJul.18,2025

-

Advanced Plastic Profile Extrusion SolutionsNewsJul.18,2025

-

PVC Profiles: The Future of Durable and Cost-Effective Construction SolutionsNewsJun.06,2025

-

PVC Pipe Extrusion LineNewsJun.06,2025

-

High-Quality Polyethylene Pipe Production LineNewsJun.06,2025

-

High-Performance Tube Production LineNewsJun.06,2025