The Core of Modern Infrastructure: Understanding ppr pipe production line

In the rapidly evolving landscape of global infrastructure, the demand for high-performance piping solutions is at an all-time high. Polypropylene Random Copolymer (PPR) pipes have emerged as a superior choice for various applications, particularly in hot and cold water distribution systems, due to their excellent thermal stability, corrosion resistance, and long service life. Investing in a state-of-the-art ppr pipe production line is paramount for manufacturers aiming to meet these stringent market requirements and ensure product quality. This comprehensive guide delves into the intricate details of PPR pipe manufacturing, highlighting the technological advancements, operational advantages, and strategic considerations for B2B stakeholders. Understanding the nuances of these production lines is crucial for optimizing output, reducing operational costs, and maintaining a competitive edge in the global market.

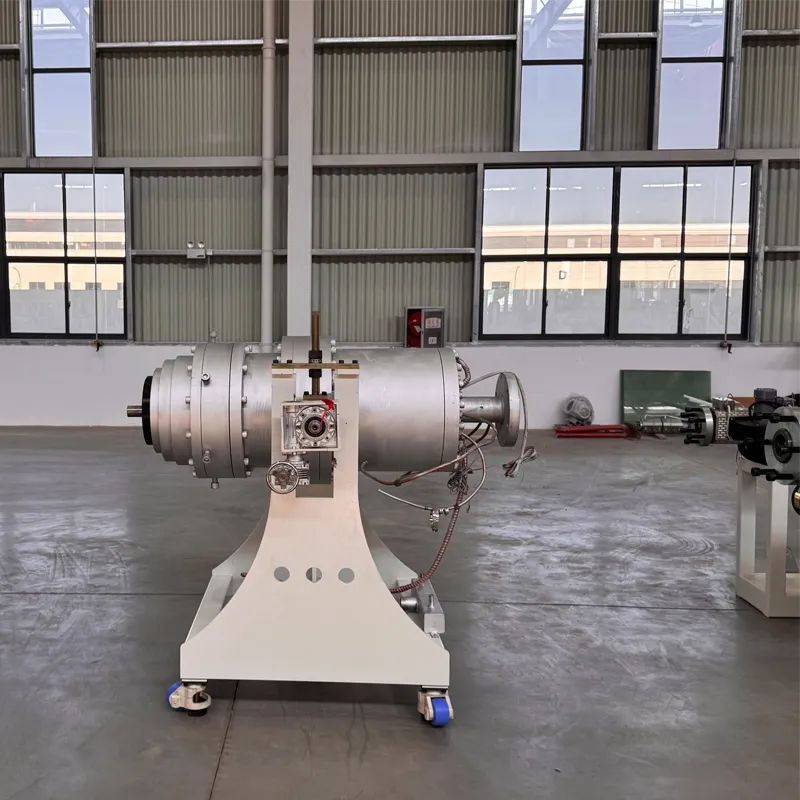

Modern PPR pipe extrusion technology focuses on precision engineering, energy efficiency, and high throughput. These sophisticated systems are designed to convert raw PPR resin into finished pipes with consistent dimensions, smooth inner surfaces, and robust mechanical properties. Manufacturers are increasingly seeking solutions that offer not only superior product quality but also intelligent automation, minimal waste, and reduced energy consumption. The market trend indicates a clear shift towards integrated solutions that can handle diverse material specifications and production capacities, ensuring adaptability for varied project demands. This strategic approach ensures that companies can efficiently scale their operations while adhering to international quality and environmental standards.

Detailed Process Flow: Crafting PPR Pipes with Precision

The manufacturing of PPR pipes involves a sophisticated multi-stage extrusion process designed to ensure material integrity and dimensional accuracy. The typical workflow of a ppr pipe production line begins with the precise feeding of virgin PPR resin granules into a single-screw extruder. This raw material, characterized by its random copolymerization of propylene with a small percentage of ethylene, offers superior high-temperature resistance and flexibility compared to other plastic pipe materials. Inside the extruder, the granules are gradually melted through controlled heating zones and mechanical shearing, transforming into a homogeneous melt. The screw design is critical here, ensuring uniform melting and thorough mixing, preventing thermal degradation of the polymer.

Following the extrusion phase, the molten PPR material is pushed through a specially designed die head, which precisely shapes it into a continuous pipe profile. The die head temperature and pressure are meticulously controlled to ensure a smooth surface finish and accurate diameter. Subsequently, the nascent pipe enters a vacuum calibration tank where a vacuum pump applies negative pressure, drawing the molten pipe against the sizing sleeve to maintain external diameter and roundness. This is a critical step for achieving tight dimensional tolerances. Immediately after calibration, the pipe is progressively cooled in a series of water cooling tanks. The controlled cooling rate is essential to prevent internal stresses and ensure the pipe's long-term mechanical strength and stability.

After adequate cooling, the now solidified PPR pipe is pulled through a multi-claw haul-off machine, which provides a consistent pulling force to maintain uniform wall thickness and line speed. This controlled pulling is vital for the entire production line's stability. Finally, the continuous pipe is cut into predetermined lengths by a precision planetary cutter, equipped with advanced dust removal systems to ensure a clean cutting edge. For smaller diameter pipes, an automatic coiler may be used instead of a cutter and stacker. Throughout this entire process, rigorous inspection standards such as ISO 15874 (for hot and cold water installations) and ANSI standards are applied to monitor dimensions, hydrostatic pressure resistance, and melt flow index (MFI), guaranteeing a service life exceeding 50 years under normal operating conditions. These pipes find extensive use in industries such as petrochemical, metallurgy, and especially in residential and commercial hot and cold water supply systems, where their energy efficiency due to low thermal conductivity and excellent corrosion resistance are significant advantages.

Technical Advantages and Innovative Features

Modern ppr pipe production line technology embodies significant advancements aimed at maximizing efficiency, precision, and operational reliability. Key advantages include high-speed extrusion capabilities, achieving production speeds that significantly reduce per-unit costs. This is often facilitated by advanced screw designs, optimized heating elements, and sophisticated cooling systems that allow for faster solidification without compromising pipe quality. Furthermore, integration of gravimetric dosing systems ensures precise material consumption and consistent wall thickness, leading to material savings and improved product integrity. The ability to monitor and adjust parameters in real-time via intuitive Human-Machine Interfaces (HMIs) contributes significantly to operational excellence and minimal downtime.

Beyond speed, the precision of these lines is unmatched. Utilizing advanced closed-loop control systems, parameters like melt temperature, pressure, line speed, and pipe dimensions (e.g., SDR ratings – Standard Dimension Ratio) are continuously monitored and self-adjusted, ensuring pipes consistently meet international standards like EN ISO 15874 for PN ratings (Nominal Pressure). This level of control minimizes variations and defects, translating into higher yield rates and reduced waste. Energy efficiency is another crucial advantage, with modern lines incorporating features such as high-efficiency motors, intelligent heating control zones, and optimized cooling system designs to significantly lower power consumption, aligning with sustainable manufacturing practices and reducing operational expenditures.

The technological prowess of a high-speed ppr pipe production line also extends to its adaptability and automation. Many contemporary lines are designed with modular components, allowing for easy expansion or reconfiguration to produce different pipe sizes or materials, including the versatility to adapt for HDPE or even PVC pipe extrusion machine for sale specifications. Fully automated systems reduce the need for manual intervention, minimizing human error and ensuring continuous, consistent production. Features like automatic coilers for smaller diameters and stackers for larger ones further streamline the post-extrusion process. This comprehensive approach to design and engineering ensures that manufacturers can achieve superior product quality, enhanced production efficiency, and significant long-term cost savings.

Key Technical Parameters for PPR Pipe Production Lines

When evaluating a ppr pipe production line, understanding its technical parameters is crucial for assessing performance and suitability for specific production needs. These specifications dictate throughput, pipe quality, and operational efficiency. The table below outlines typical ranges for critical parameters found in high-speed PPR pipe extrusion lines, providing a benchmark for prospective buyers and technical decision-makers.

| Parameter | Typical Range for High-Speed PPR Line | Importance/Remarks |

|---|---|---|

| Pipe Diameter Range (OD) | 20mm - 160mm (standard); up to 200mm+ (specialized) | Determines versatility for various applications (e.g., residential vs. industrial). |

| Extruder Type | Single Screw Extruder (e.g., SJ-series) | Optimized for PPR melt characteristics, L/D ratio 33:1 to 40:1 common. |

| Maximum Production Speed | Up to 20-30 m/min for smaller diameters; 5-10 m/min for larger. | Key determinant of output capacity and efficiency. |

| Main Motor Power | 37 kW - 110 kW (depending on extruder size) | Directly impacts processing power and energy consumption. |

| Total Installed Power | 80 kW - 250 kW (full line, including peripherals) | Overall energy footprint of the entire production setup. |

| Line Dimensions (L x W x H) | Approx. 20m - 30m x 2m x 2.5m | Space requirements for factory layout and installation. |

| Cooling Tank Length | 4m - 10m per tank (multiple tanks typically used) | Adequate cooling critical for pipe quality and higher line speeds. |

| Control System | PLC-based with HMI, typically Siemens or Schneider Electric | Enables automation, precision control, and ease of operation. |

These parameters collectively define the capabilities of a ppr pipe production line. For instance, a higher maximum production speed combined with a wide diameter range indicates a versatile and high-volume system, suitable for diverse market demands. Understanding these technical specifications is essential for making an informed investment decision, ensuring the selected line aligns perfectly with production goals and industry requirements.

Applications Across Diverse Industries

PPR pipes produced from a robust ppr pipe production line have become indispensable across a multitude of sectors due to their inherent advantages such as high-temperature resistance, excellent chemical inertness, and superior durability. Their primary application lies in the distribution of hot and cold water in residential, commercial, and industrial buildings. Unlike traditional metallic pipes, PPR pipes do not corrode, scale, or leach harmful substances into the water, ensuring hygienic and safe drinking water supply over decades. This makes them ideal for potable water systems, significantly reducing maintenance costs and ensuring compliance with health standards.

Beyond plumbing, PPR pipes are extensively utilized in heating systems, including radiant floor heating and central heating networks, owing to their ability to withstand continuous high temperatures and pressures (up to PN20 and PN25 ratings). Their low thermal conductivity also means minimal heat loss, contributing to energy efficiency in these systems. In industrial settings, PPR pipes serve as reliable conduits for conveying various chemicals, acids, and alkalis due to their excellent chemical resistance, making them suitable for sectors like chemical processing, metallurgy, and mining. Their resistance to abrasion and stress cracking further enhances their appeal in demanding industrial environments where consistent flow and minimal leakage are critical.

Furthermore, PPR pipes produced by an advanced ppr pipe production line are increasingly being adopted in agricultural irrigation systems, offering a durable and cost-effective alternative to traditional pipes. Their lightweight nature facilitates easy installation, and their resistance to environmental factors ensures long-term performance in outdoor conditions. In the petrochemical industry, while often heavy-duty materials like steel are used, PPR can find niche applications for less aggressive fluids or specific process lines where its corrosion resistance is advantageous. The versatility and long-term economic benefits derived from their extended lifespan and low maintenance requirements cement PPR pipes as a preferred choice across diverse and critical infrastructure applications.

Manufacturer Comparison: PPR vs. PVC Extrusion Capabilities

When sourcing an extrusion line, industrial buyers often consider manufacturers that offer a broad portfolio, covering various pipe materials. While the core focus is on a ppr pipe production line, many leading manufacturers also specialize in equipment like a high-performance pvc pipe extrusion machine for sale or a robust pvc extruder machine for sale. Understanding the distinctions and similarities in these offerings is crucial for a well-rounded procurement strategy.

| Feature/Material | PPR Pipe Extrusion Line | PVC Pipe Extrusion Line | Remarks |

|---|---|---|---|

| Primary Material | Polypropylene Random Copolymer (PPR) | Polyvinyl Chloride (PVC), including uPVC and cPVC | Distinct material properties dictate application. |

| Extruder Type | Single Screw Extruder (optimized for high melt viscosity) | Conical Twin Screw Extruder (for sensitive PVC compounds) | Different screw geometries for optimal processing. |

| Die Head Design | Spiral or Basket type | Spiral or Lattice type (for rigid PVC) | Ensures uniform melt flow and pipe shaping. |

| Cooling System | Water spray/immersion tanks (requires precise temperature control) | Vacuum calibration and water cooling baths (often longer) | Critical for dimensional stability and crystallization. |

| Application Focus | Hot/cold water supply, heating systems | Drainage, sewage, conduit, agricultural, industrial (PVC/CPVC) | Each material excels in different use cases. |

| Cost-Effectiveness | Higher initial material cost, lower long-term maintenance. | Lower initial material cost, widely accepted for general use. | Balance of material and operational expenses. |

While a dedicated ppr pipe production line provides optimized performance for PPR, manufacturers often offer comprehensive solutions, leveraging similar core extrusion principles but adapting them to the specific rheological and thermal properties of each polymer. Companies seeking to diversify their production capabilities may find value in suppliers who demonstrate expertise across multiple plastic pipe types, ensuring a reliable partnership for various infrastructure projects.

Customization and Tailored Solutions

Recognizing that no two manufacturing operations are identical, leading suppliers of ppr pipe production line equipment offer extensive customization options. This flexibility allows clients to configure systems that precisely meet their unique production demands, factory layout constraints, and budget considerations. Customization can range from specific pipe diameter ranges and wall thickness capabilities to integrating advanced features like multi-layer co-extrusion for composite pipes or specialized coloring units. This ensures that the investment delivers maximum return on efficiency and product diversification.

Clients can also specify the level of automation desired, from semi-automated setups requiring more manual intervention to fully automated lines with integrated robotic handling, online quality control systems (e.g., ultrasonic thickness gauges), and centralized data management. Furthermore, energy recovery systems, specialized filtration units, and enhanced safety features can be incorporated based on regional regulations and corporate sustainability goals. A reputable manufacturer works closely with clients through detailed consultation, utilizing Computer-Aided Design (CAD) and Computational Fluid Dynamics (CFD) to simulate line performance and optimize layout, ensuring the tailored ppr pipe production line not only meets current needs but also allows for future scalability and technological upgrades. This collaborative approach leads to a robust, future-proof investment.

Building Trust: Our Commitment to Quality and Support

As a leading provider in extrusion technology, our commitment extends beyond delivering a high-quality ppr pipe production line. We understand that purchasing capital equipment is a significant decision, requiring trust in the supplier's expertise, product reliability, and ongoing support. Our long-standing history in the industry, coupled with numerous ISO certifications (e.g., ISO 9001 for Quality Management) and adherence to international electrical and safety standards (e.g., CE marking for European markets), underscores our authoritative position. We pride ourselves on transparent communication, from initial consultation through to after-sales service.

Frequently Asked Questions (FAQ)

-

Q: What is the typical lead time for a new PPR pipe production line?

A: Our standard delivery cycle typically ranges from 60 to 90 working days from order confirmation, depending on the level of customization and current production schedule. Expedited options may be available upon request. -

Q: What kind of warranty and after-sales support do you provide?

A: We offer a comprehensive 12-month warranty on mechanical and electrical components. Our dedicated global customer support team provides remote technical assistance, on-site installation and commissioning services, operator training, and readily available spare parts to ensure continuous operation. -

Q: Can your lines process recycled PPR material?

A: Our extruders are designed to handle a percentage of high-quality recycled PPR, provided it meets specific melt flow index and purity standards. We can consult on suitable material specifications to achieve desired pipe quality.

Delivery Cycle & Quality Assurance

Our commitment to delivery excellence is underpinned by rigorous project management and supply chain efficiency. Each ppr pipe production line undergoes extensive factory acceptance testing (FAT) before shipment, simulating real-world operating conditions to ensure all performance parameters are met or exceeded. Clients are welcome to participate in these tests. Upon successful FAT, equipment is carefully packaged for international transit.

Warranty and Customer Support

We stand by the quality of our engineering with a robust warranty program and a proactive customer support philosophy. Our global service network ensures rapid response times for technical inquiries, troubleshooting, and spare parts supply. Experienced engineers are available for on-site installation, commissioning, and comprehensive operator training, empowering your team to maximize the efficiency and longevity of your investment. This holistic approach ensures minimal downtime and sustained high-quality production for our partners.

Conclusion: Investing in Future-Proof Pipe Manufacturing

The decision to invest in a state-of-the-art ppr pipe production line is a strategic move for any manufacturer aiming to excel in the competitive plastic pipe industry. These advanced systems offer unparalleled precision, efficiency, and versatility, enabling the production of high-quality PPR pipes that meet stringent international standards and serve critical infrastructure needs. From their meticulous manufacturing process and robust technical advantages to their widespread application across various sectors, PPR pipe extrusion lines represent the pinnacle of modern industrial engineering. By choosing a reputable manufacturer committed to quality, customization, and comprehensive after-sales support, businesses can secure a future-proof investment that drives sustainable growth and profitability in the long term. This strategic partnership ensures access to cutting-edge technology and unwavering operational assistance, laying the foundation for consistent excellence in pipe manufacturing.

References

- Polymer Extrusion. "Extrusion Process and Equipment for Plastic Pipes." Journal of Plastics Technology, Vol. 45, No. 3, 2021.

- ISO 15874 Standard. "Plastics piping systems for hot and cold water installations - Polypropylene (PP)." International Organization for Standardization, 2013.

- Advanced Materials Research. "Mechanical and Thermal Properties of Polypropylene Random Copolymer (PPR) Pipes." Vol. 1234, 2022.

- Chemical Engineering Journal. "Corrosion Resistance of Plastic Piping in Industrial Applications." Vol. 150, 2018.

-

Innovative Solutions in PVC Pipe Production LineNewsJul.18,2025

-

Innovative Solutions in Pipe Extrusion Production LineNewsJul.18,2025

-

Advanced Plastic Profile Extrusion SolutionsNewsJul.18,2025

-

PVC Profiles: The Future of Durable and Cost-Effective Construction SolutionsNewsJun.06,2025

-

PVC Pipe Extrusion LineNewsJun.06,2025

-

High-Quality Polyethylene Pipe Production LineNewsJun.06,2025

-

High-Performance Tube Production LineNewsJun.06,2025