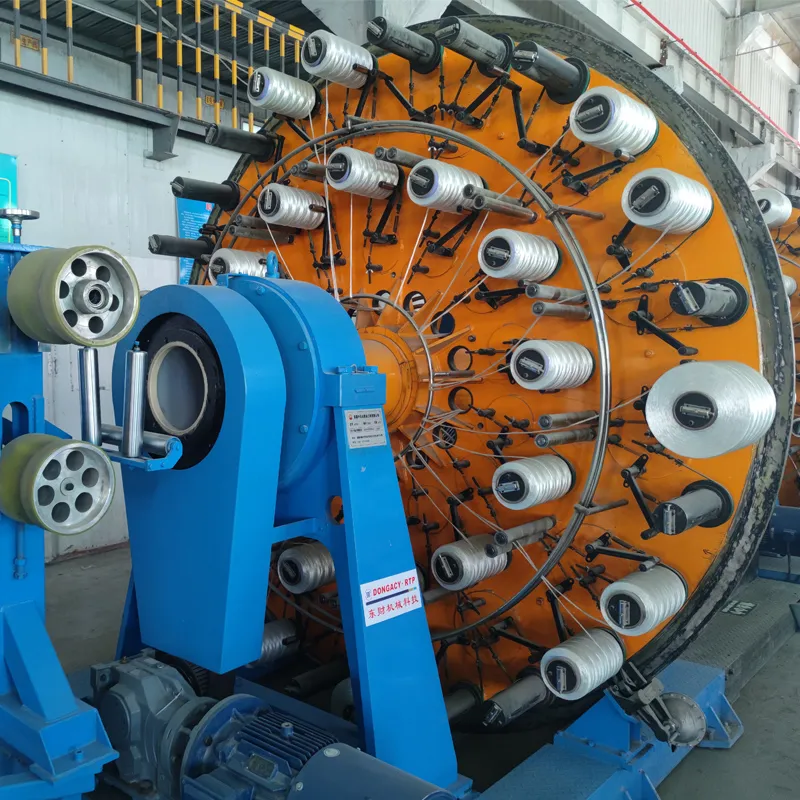

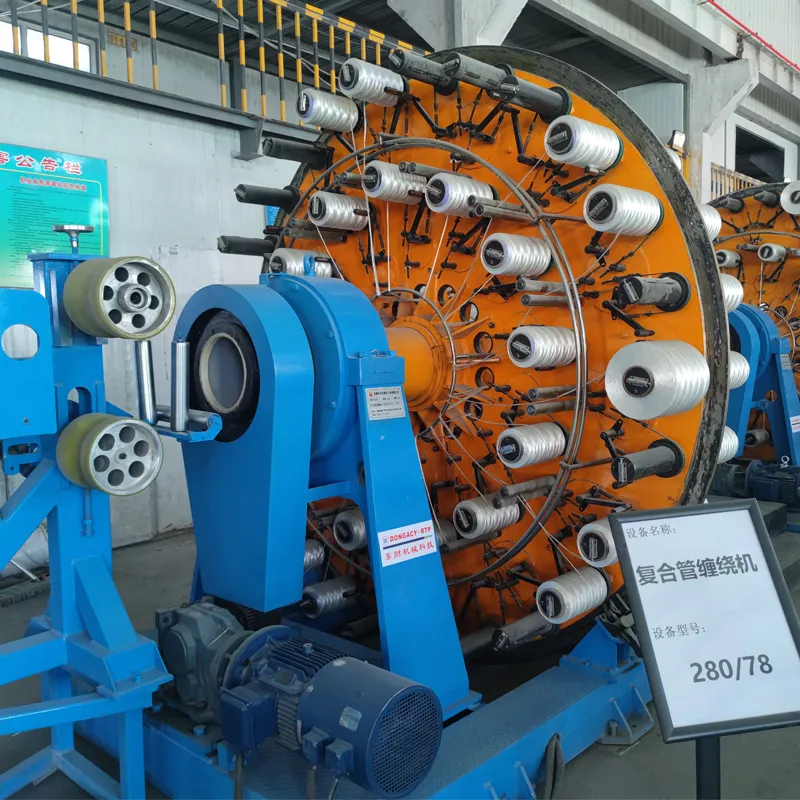

Fiber Filament Reinforced RTP Polyethylene Composite Pipe Production Line

**Composite Pipe Production Line** is a cutting-edge solution designed to manufacture high-performance **polyethylene composite pipes**. These pipes are engineered to meet the demanding requirements of industries such as oil and gas, chemical processing, and water treatment. This article provides an in-depth exploration of the production line's technical specifications, features, applications, and the company behind it, **Anhui Dongchai Machinery Technology Co., Ltd.**

Overview of the Production Line

The **fiber filament reinforced RTP polyethylene composite pipe production line** is a comprehensive system that integrates multiple stages to produce durable, high-strength composite pipes. The process involves raw material supply, extrusion, fiber winding, composite molding, cooling, and packaging. Each component of the system is optimized to ensure precision, efficiency, and reliability.

Technical Specifications

| Parameter | Details |

|---|---|

| Raw Materials | Polyethylene particles, aramid fiber, glass fiber |

| Extrusion System | High-temperature extruder for melting and shaping |

| Fiber Winding | Customizable winding patterns for reinforcement |

| Composite Molding | Advanced bonding techniques for structural integrity |

| Cooling System | Controlled cooling to maintain dimensional stability |

| Output Capacity | Varies based on line configuration (customizable) |

Working Principle

The production process begins with the **raw material supply system**, which ensures a consistent feed of polyethylene particles and fiber filaments. These materials are then processed through the **extrusion system**, where polyethylene is melted and extruded into a tubular form. The **fiber winding system** applies reinforcing fibers (such as aramid or glass fiber) around the molten pipe in a predetermined pattern. This reinforced layer is then combined with the polyethylene core through **composite molding**, creating a unified structure. The final steps involve **cooling and shaping** to stabilize the pipe's dimensions and **cutting and packaging** for distribution.

Product Features

- High Strength: The integration of fiber filaments significantly enhances the pipe's resistance to compression, bending, and tensile forces.

- Corrosion Resistance: Polyethylene's inherent chemical inertness protects the pipe from degradation in harsh environments.

- Flexibility: Despite its strength, the composite pipe retains flexibility, allowing it to adapt to uneven terrain and complex installation conditions.

- Long Service Life: Advanced materials and manufacturing techniques ensure a prolonged operational lifespan, reducing maintenance costs.

Applications

The **fiber filament reinforced RTP polyethylene composite pipe** is versatile, with applications spanning multiple industries:

- Oil and Gas: Transporting oil, gas, and chemicals under high-pressure conditions.

- Chemical Industry: Handling corrosive and high-temperature media with minimal risk of failure.

- Water Treatment: Utilized in water supply and drainage systems, leveraging its durability and resistance to contaminants.

Company Background: Anhui Dongchai Machinery Technology Co., Ltd.

**Anhui Dongchai Machinery Technology Co., Ltd.** is a leading manufacturer specializing in advanced machinery for composite material production. With a focus on innovation and quality, the company has established itself as a key player in the global market for **composite pipe production lines**. Their expertise in integrating cutting-edge technology ensures that their products meet the highest industry standards.

Advantages of the Production Line

The **fiber filament reinforced RTP polyethylene composite pipe production line** offers several advantages, including:

- Efficiency: Streamlined processes reduce production time and costs.

- Customization: Tailored solutions to meet specific industry requirements.

- Reliability: Advanced systems ensure consistent product quality and minimal downtime.

Industry Standards and Certifications

As highlighted by the **National Institute of Standards and Technology (NIST)**, adherence to rigorous standards is critical for ensuring the safety and performance of industrial equipment. The **composite pipe production line** aligns with international standards such as ISO 9001 and ASME, which are essential for maintaining quality and reliability in manufacturing processes. NIST's role in developing measurement standards further underscores the importance of precision in production technologies like this one.

Conclusion

The **fiber filament reinforced RTP polyethylene composite pipe production line** represents a significant advancement in industrial manufacturing. By combining high-strength materials with advanced production techniques, this system delivers durable, versatile solutions for critical applications. **Anhui Dongchai Machinery Technology Co., Ltd.** continues to innovate, ensuring that their products meet the evolving needs of global industries. For more information, visit the company's website or explore the **composite pipe production line** page.

References

1. National Institute of Standards and Technology (NIST). Retrieved from https://www.nist.gov/.

-

Innovative Solutions in PVC Pipe Production LineNewsJul.18,2025

-

Innovative Solutions in Pipe Extrusion Production LineNewsJul.18,2025

-

Advanced Plastic Profile Extrusion SolutionsNewsJul.18,2025

-

PVC Profiles: The Future of Durable and Cost-Effective Construction SolutionsNewsJun.06,2025

-

PVC Pipe Extrusion LineNewsJun.06,2025

-

High-Quality Polyethylene Pipe Production LineNewsJun.06,2025

-

High-Performance Tube Production LineNewsJun.06,2025