As global infrastructure projects drive the evolution of pipeline solutions, the composite pipe production line—notably the Fiber Filament Reinforced RTP Polyethylene Composite Pipe Production Line (product details)—is setting new industry benchmarks. Applications across oil & gas, petrochemical, metallurgy, municipal water, and mining are evolving, demanding advanced, cost-effective, and highly reliable piping systems. In this in-depth article, we analyze the latest market trends, manufacturing processes, technology parameters, application advantages, and offer valuable comparison insights to guide your next infrastructure investment.

Market Trends Driving the Adoption of Composite Pipe Production Lines

- Global demand for advanced composites in pipelines is expected to reach USD 11.2 billion by 2028, with an estimated CAGR of 5.9% (Source: MarketsandMarkets 2023).

- HDPE machine price optimization has enabled cost-effective upgrades without compromising quality or compliance.

- Pipe manufacturers are expanding product lines to accommodate high-pressure, anti-corrosive, and energy-efficient solutions—increasingly specified for oil & gas, chemicals, marine, and waterworks projects.

- ISO, ANSI, and API conformance remains critical for large government and industrial tenders.

- Growing partnership networks, particularly in Asia and the Middle East, boost technology transfer and bespoke solutions.

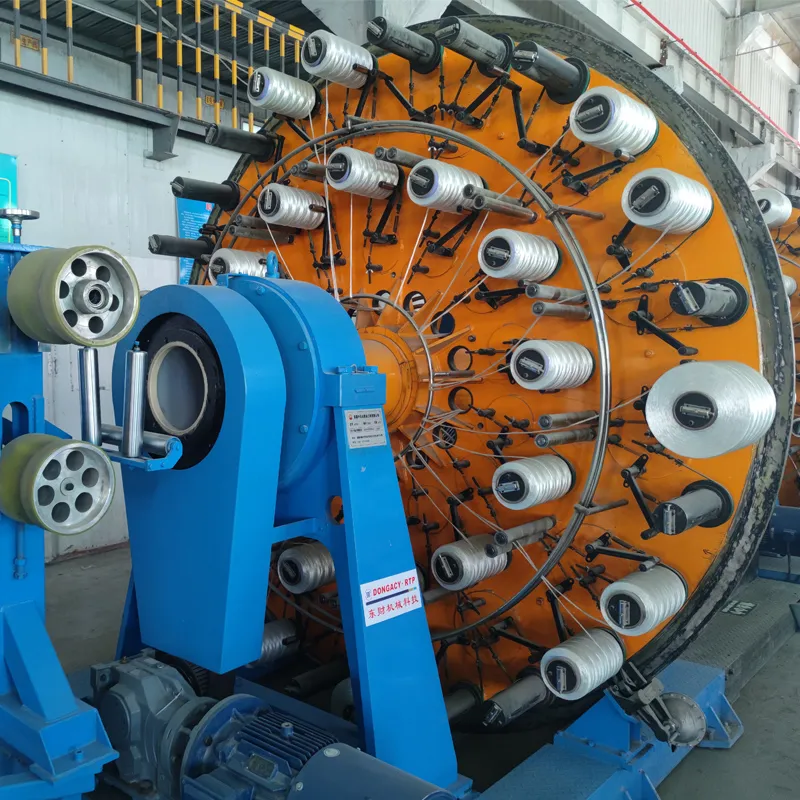

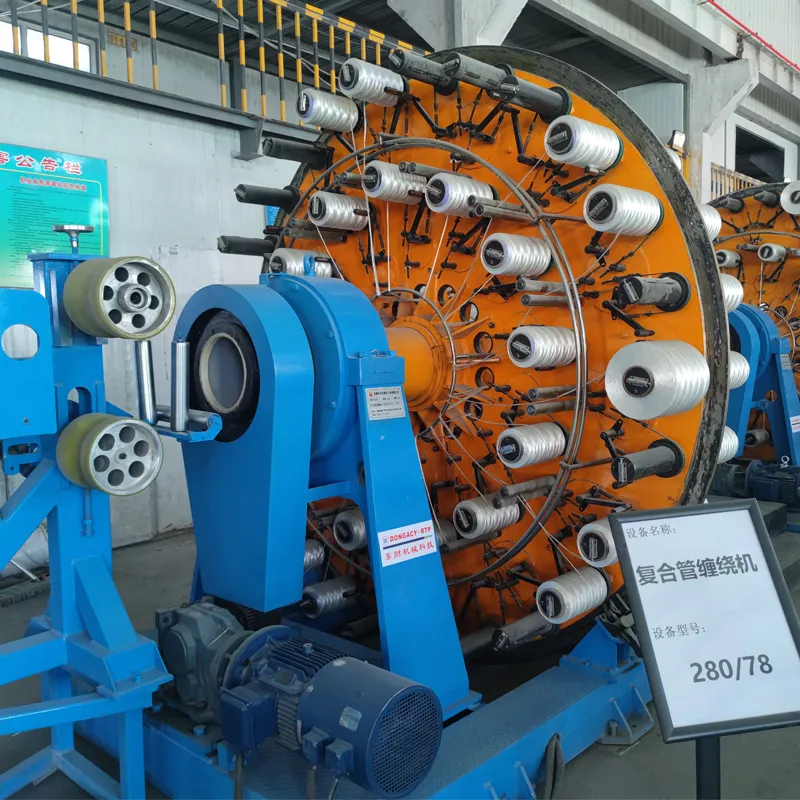

Detailed Manufacturing Process of Composite Pipe Production Line

- Raw Material Standard: High-density polyethylene (HDPE, grade PE100 or above), fiber glass, aramid or carbon fibers.

- Processing Equipment: Precision extruders, advanced filament winding machines, and CNC cutting stations.

- Key Detection Points: ISO 9001 and ANSI/API standards, ultrasonic wall thickness checks, hydrostatic pressure testing.

- Production Speed: Up to 12 meters/minute for pipes up to DN630.

Technical Parameters: Composite Pipe Production Line vs. Competitors

| Parameter | Fiber Filament Reinforced RTP Composite | Conventional HDPE Pipe Line | Steel-reinforced PE Pipe Line |

|---|---|---|---|

| Pipe Diameter Range (mm) | 50–630 | 20–1200 | 50–1200 |

| Working Pressure (MPa) | Up to 4.0 | Up to 1.6 | Up to 2.5 |

| Line Speed (m/min) | 2 – 12 | 0.3 – 6 | 1 – 8 |

| Reinforcement | Glass/Aramid/Carbon Fibers | None | Steel Wires/Mesh |

| Expected Lifespan (Years) | 50+ | 25–50 | 30–50 |

| Corrosion Resistance | Excellent (API/ISO Certified) | Good | Moderate |

| Thermal Stability | Up to 90°C | Up to 60°C | Up to 80°C |

| Relative Cost | Medium (10–30% above HDPE, lower than metal) | Low | Medium–High |

— Pipeline Industry Journal 2023

Data Visualizations

Working Pressure Capabilities

Composite Pipe Production Line Market Share (2023 est.)

Service Life Projection (Expected Lifespan)

Technical Advantages of Fiber Filament Reinforced RTP Polyethylene Composite Pipe Production Line

- Multi-Layer Structure: Utilizes high-performance fibers between polyethylene layers for ultra-high burst pressure resistance, while achieving extraordinary flexibility and lightweight characteristics.

- Superior Anti-Corrosion: Completely corrosion-resistant (certified by ISO 4427, API 15S), ideal for saline, acidic, or contaminated soil conditions.

- Longevity & Minimal Maintenance: Designed for 50+ years of service under demanding conditions with little to no degradation, as validated by long-term hydrostatic pressure tests.

- Thermal Stability: Maintains mechanical performance at temperatures up to 90°C, exceeding typical HDPE piping system limitations.

- Cost Efficiency: While upfront investment is typically 10–30% above standard HDPE (see hdpe machine price analysis), the total cost of ownership is significantly lower due to reduced labor, corrosion losses, and life-cycle maintenance.

Use Case Scenarios for Composite Pipe Production Lines

- Oil & Gas Transmission: Long-distance, high-pressure transport with minimal downtime and outstanding chemical resistance.

- Municipal Water Supply: Large-diameter mainlines, both potable and waste water, leveraging non-corrosive, lightweight attributes for rapid trenchless installations.

- Chemical Processing Plants: Aggressive media (acidic or alkaline), where composite pipe production line materials outperform traditional metal solutions.

- Mining and Slurry: High-abrasion, high-impact fluid delivery; pipe durability validated by repeated ISO 4427 and UK WRAS testing.

- District Heating/Cooling: Pre-insulated options with stable inner and outer layers for reliable hot/cold fluid transport, up to 90°C operation.

Real-World Application Case Study: Fiber RTP Composite Pipe in Persian Gulf Waterworks

Length: 120 km

Requirements: Corrosion-free, flexible pipe for harsh saline environments and rapid deployment.

Solution: Fiber Filament Reinforced RTP Polyethylene Composite Pipe deployed via modular composite pipe production line

Impact: Achieved 42% installation time reduction, zero leakage after 3 years, $3.8M cost savings over steel-pipe alternatives.

End User: Gulf Petrochemical Corp.

Certifications: ISO 9001, API 15S, National Water Authority Approval

Manufacturer Comparison: Composite Pipe Production Lines

| Manufacturer | Country | Key Technology | Production Speed | After-Sales Service | Major Clients |

|---|---|---|---|---|---|

| AHDC Machinery (Fiber Filament RTP) | China | Advanced multi-fiber winding, CNC cutting, ISO/API Certification | Up to 12 m/min | 24/7, Global Installation | Sinopec, Pemex, Municipal Waterworks |

| Pultruline GmbH | Germany | Epoxy-fiber pultrusion, automated control | 6–9 m/min | EMEA, Remote Support | BASF, European Utilities |

| TechCorr Industries | India | Steel-Reinforced HDPE, continuous extrusion | 7 m/min | Regional, Onsite Training | L&T, Indian Railways, Metros |

Tailored Solutions & Customization

- Pipe customization: diameter (30–1200mm), working pressure, reinforced material (glass, aramid, carbon).

- Integration of real-time monitoring—inline wall-thickness gauges, eddy current sensors.

- Custom certification pathways: ISO, ANSI, WRAS, API, NSF for international projects.

- Modular line extension/automation for future capacity upgrades.

- Bespoke surface color coding, jointing systems, and on-site installation teams available.

Contact our engineers to get a project-specific quote, full technical proposal, and ROI estimation, including hdpe machine price breakdowns for accurate budget planning.

FAQ: Advanced Composite Pipe Technology

Guarantee, Support, and Delivery Terms

- All lines exported come with ISO 9001 and API 15S certification, factory acceptance test certificates, and full technical documentation in English.

- Warranty: 2 years standard, with up to 5 years extended warranty available.

- Startup support: On-site or remote commissioning, operator training, and maintenance guidance.

- Spare & wear parts: In-stock shipment and global warranty fulfillment.

- Post-sale engineering consultation: Included for 12 months; optional extension contract for major/complex projects.

Need help with compliance, financing, or hdpe machine price analysis? Contact our technical and commercial teams for case-specific consultation.

Industry References and Authority Citations

- Pipeline Industry Journal (2023): [website]

- MarketsandMarkets, "Composite Pipes Market", 2023: [report]

- ISO 4427 Certification: [ISO Official]

- ScienceDirect – Advances in Reinforced Thermoplastic Pipe (RTP) Technologies: [link]

- WaterOnline Forum: RTP Pipe Effectiveness [discussion]

-

Innovative Solutions in PVC Pipe Production LineNewsJul.18,2025

-

Innovative Solutions in Pipe Extrusion Production LineNewsJul.18,2025

-

Advanced Plastic Profile Extrusion SolutionsNewsJul.18,2025

-

PVC Profiles: The Future of Durable and Cost-Effective Construction SolutionsNewsJun.06,2025

-

PVC Pipe Extrusion LineNewsJun.06,2025

-

High-Quality Polyethylene Pipe Production LineNewsJun.06,2025

-

High-Performance Tube Production LineNewsJun.06,2025