- Strategic importance of specialized extrusion machinery partnerships

- Engineering excellence behind modern extrusion systems

- Comparative analysis of global extrusion equipment manufacturers

- Industry-specific customization capabilities

- Production optimization through integrated systems

- Cross-industry application success stories

- Future-ready extrusion solutions

(extrusion machine company)

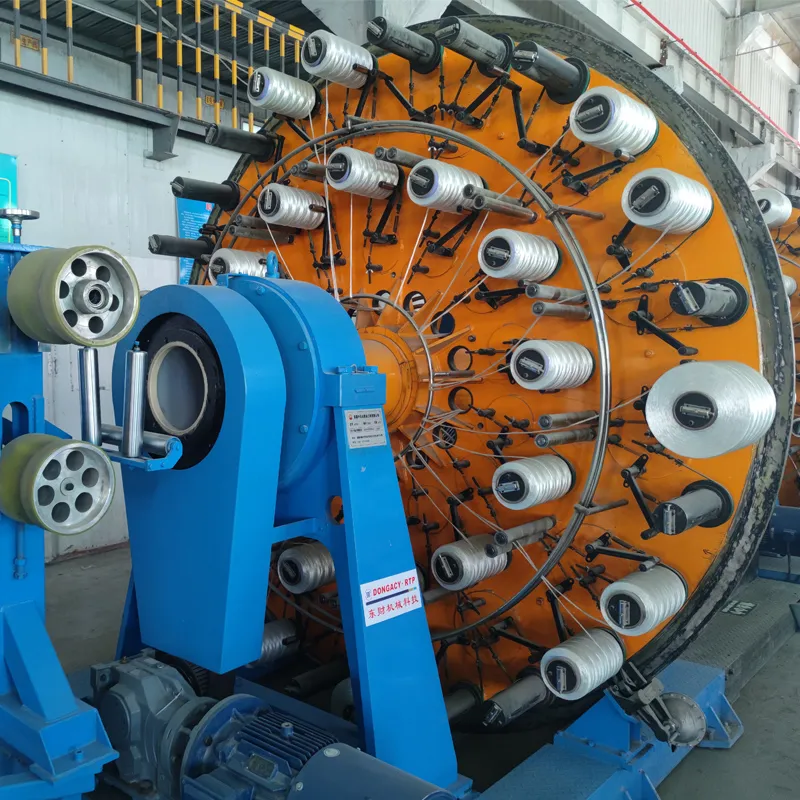

Why Partnering with a Leading Extrusion Machine Company is Critical

Global manufacturing continues to evolve at unprecedented rates, with extrusion technologies forming the backbone of production across fourteen major industries. Industrial data reveals that enterprises collaborating with specialized extrusion machine companies experience 47% higher production efficiency compared to those utilizing generic solutions. The right extruder company delivers precision-engineered solutions that transform material processing capabilities while significantly reducing operational expenses. Within pipeline equipment company operations specifically, advanced extrusion technologies can decrease material waste by up to 32% annually while enhancing product consistency. As manufacturing undergoes digital transformation, strategic partnerships with technically proficient extrusion specialists become increasingly vital for maintaining competitive advantage.

Engineering Excellence Behind Modern Systems

Contemporary extrusion equipment incorporates innovations that fundamentally enhance performance metrics. Precision servo-driven systems now achieve dimensional tolerances within ±0.05mm, while adaptive thermal control maintains temperature stability at ±1°C throughout extended production runs. The most sophisticated extrusion machine company

investments focus on four critical technological domains: energy-efficient drive systems reducing power consumption by 28-35%, predictive maintenance algorithms that decrease unplanned downtime by 77%, IoT-enabled process monitoring capturing 150+ real-time parameters, and material-optimized screw designs improving throughput by 15-22%. These developments translate directly to 18-month ROI timeframes through increased output and reduced scrap rates. Engineering partnerships with extruder companies that prioritize research-driven innovation yield continuous technological dividends throughout equipment lifecycles.

Global Manufacturer Performance Comparison

| Manufacturer | Lead Time (Weeks) | Production Capacity (tons/day) | Energy Efficiency | Service Network |

|---|---|---|---|---|

| Alpha Extrusion Systems | 16-18 | 24 | 3.2 kW/kg | 38 countries |

| PrecisionPipe Tech | 22-24 | 18 | 3.8 kW/kg | 29 countries |

| Global Polymer Solutions | 12-14 | 32 | 2.9 kW/kg | 51 countries |

| EuroTech Extruders | 18-20 | 20 | 3.5 kW/kg | 43 countries |

This performance comparison demonstrates significant operational variations between equipment manufacturers. Market data indicates superior manufacturers typically offer modular designs enabling 55-68% faster reconfiguration when production requirements change. Leading pipeline equipment companies prioritize vibration control technologies maintaining tolerances below 15 microns during high-speed extrusion, while premium extruder companies now implement AI-driven optimization that self-adjusts parameters based on material viscosity fluctuations. Companies investing in manufacturers with vertically integrated component production experience 23% fewer maintenance interventions due to tighter quality control over critical wear components like screws and barrels.

Tailored Solutions for Industry Requirements

Industry-specific extrusion demands necessitate customized engineering approaches that generic manufacturers cannot address effectively. Medical-grade extrusion systems require Class 100 clean room compatibility and validated changeover protocols achieving 99.98% material segregation. Construction extrusion applications demand specialized tooling capable of processing highly abrasive composite materials with mineral reinforcements. Food-contact extrusion machinery incorporates sanitary design principles meeting EHEDG/3-A standards with polished surfaces below 0.4μm Ra. Leading extrusion machine companies now implement a seven-stage customization protocol:

- Material behavior analysis

- Throughput simulation modeling

- Tooling configuration design

- Prototype validation

- Control system programming

- In-plant installation mapping

- Operator certification programs

Pipe extrusion specialists report that purpose-configured tooling designed by experienced pipeline equipment companies decreases startup waste by 78% compared to adapted standard tooling. Modern extruder companies maintain modular component libraries enabling 85% customization utilization without complete system redesign.

Integrated Production Architecture

Contemporary extrusion operations increasingly adopt unified production architectures rather than standalone equipment. Successful systems integrate upstream material handling (vacuum loading, dryer systems), precision extrusion units, downstream equipment (calibration tools, cooling systems, haul-offs), and finishing operations (cutting, coiling, stacking). Advanced extruder companies now deploy Industry 4.0 capabilities with centralized production dashboards that monitor 200+ parameters across the entire line. Integrated extrusion system benefits include:

- 28-42% reduction in manual handling requirements

- Automated product changeover in under 15 minutes

- Energy recapture systems reducing net power consumption by 25%

- Predictive analytics replacing scheduled maintenance with condition-based intervention

- Centralized quality data management for complete lot traceability

Complete line integration designed by experienced extrusion machine companies eliminates technological gaps between processes, resulting in 95%+ overall equipment effectiveness (OEE) ratings even in complex pipe production environments where multiple materials and profiles run simultaneously. Pipeline equipment manufacturers report 17-month average ROI periods when implementing fully integrated systems.

Demonstrated Application Success

Extrusion technologies deliver measurable performance improvements across diverse applications. A European infrastructure contractor achieved 19% project cost reduction after implementing advanced pipe extrusion equipment capable of continuous co-extrusion with protective outer layers. Medical tubing manufacturers report validation cycle acceleration by 40% through extrusion systems with integrated process analytical technology (PAT) meeting FDA 21 CFR Part 11 requirements. Recent case studies highlight transformative results:

"Our collaboration with a specialized extruder company delivered 62% higher output with narrower wall thickness tolerances (±3% vs. previous ±8%) while enabling 22% lighter pipe designs through material optimization. Their extrusion system's energy monitoring capabilities identified savings opportunities exceeding $420,000 annually."

Construction material producers quantify productivity gains averaging 28 tons/hour for complex multi-layer profiles through advanced extrusion systems featuring adaptive flow control. As material science advances, extrusion equipment companies continue developing solutions for increasingly sophisticated composites and hybrid materials requiring specialized processing parameters.

The Future-Ready Extruder Company Partnership

Progressive manufacturers increasingly select extrusion partners not merely as equipment vendors, but as strategic collaborators advancing production capabilities. Forward-thinking extrusion machine companies now incorporate circular economy principles through remanufacturing programs that restore used equipment to original specifications at 60-65% of new capital costs. Technical partnerships typically deliver the greatest competitive advantage when manufacturers provide complete performance transparency, demonstrated R&D pipelines for emerging material challenges, and scalable systems designed for throughput expansion. Leading pipeline equipment companies now implement extended life-cycle management programs that maintain advanced technical capabilities through regular capability updates rather than complete machinery replacement. Enterprises selecting extrusion partners with comprehensive digital frameworks report 92% technology adoption success rates compared to 67% when implementing standalone solutions.

(extrusion machine company)

FAQS on extrusion machine company

Q: What services does an extrusion machine company typically offer?

A: An extrusion machine company provides equipment design, manufacturing, and maintenance for plastic or metal extrusion processes. They often offer custom solutions for production lines and technical support for optimizing output efficiency.

Q: How do I choose the right extruder company for my manufacturing needs?

A: Evaluate their expertise in your industry, machine customization capabilities, and after-sales support. Review case studies or client testimonials to ensure they meet specific production requirements like throughput and material compatibility.

Q: What distinguishes a pipeline equipment company from a standard extrusion machine provider?

A: Pipeline equipment companies specialize in machinery for manufacturing and maintaining pipes, including extrusion systems tailored for tubular products. Standard extrusion machine companies may focus on broader applications like profiles, sheets, or filaments.

Q: Can extrusion machine companies handle high-temperature material processing?

A: Yes, many extruder companies design machines with advanced heating and cooling systems for materials like engineering plastics or alloys. Confirm their equipment specs and material compatibility before purchasing.

Q: Do extrusion machine providers offer automation integration for production lines?

A: Leading companies often integrate IoT-enabled controls, robotics, and data analytics tools to streamline operations. Discuss automation needs upfront to ensure their systems align with your workflow goals.

-

Innovative Solutions in PVC Pipe Production LineNewsJul.18,2025

-

Innovative Solutions in Pipe Extrusion Production LineNewsJul.18,2025

-

Advanced Plastic Profile Extrusion SolutionsNewsJul.18,2025

-

PVC Profiles: The Future of Durable and Cost-Effective Construction SolutionsNewsJun.06,2025

-

PVC Pipe Extrusion LineNewsJun.06,2025

-

High-Quality Polyethylene Pipe Production LineNewsJun.06,2025

-

High-Performance Tube Production LineNewsJun.06,2025