- Technical advantages driving modern extrusion efficiency

- Critical specifications defining pelletizing performance

- Comparative analysis of leading equipment manufacturers

- Data-backed industry applications and success metrics

- Customization frameworks for specialized requirements

- Material science considerations for PVC formulations

- Operational optimization strategies for production lines

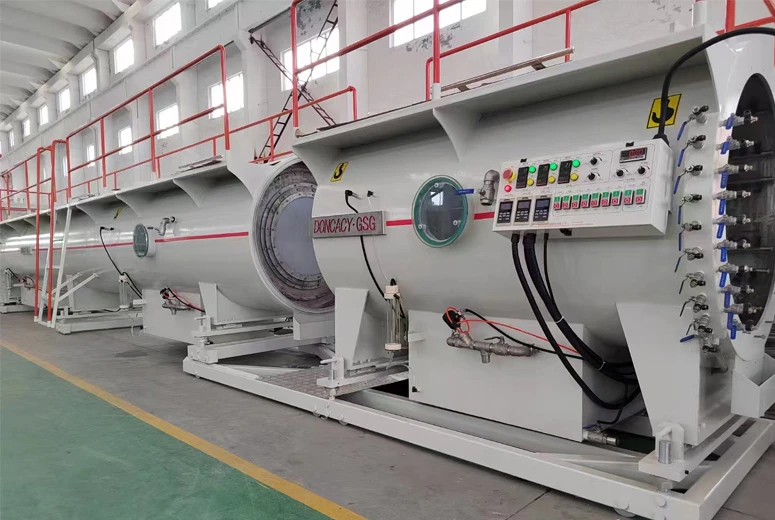

(pvc pelletizing extrusion line)

Transformative Capabilities in PVC Pelletizing Extrusion

Contemporary extrusion pelletizing machines integrate engineering breakthroughs that elevate production efficiency by 40-60% over legacy systems. These integrated lines combine twin-screw extrusion with precision cutting technologies, achieving throughput capacities from 500kg to 3,500kg/hour. Advanced thermal control systems maintain material temperatures within ±1.5°C, crucial for preserving PVC compound integrity during processing.

The synchronization of material feeding, melting, and pellet formation stages reduces energy consumption by approximately 30% compared to segmented equipment. Modern designs incorporate self-cleaning barrels and quick-change die plates, cutting downtime during material transitions by 70%.

Technical Specifications Dictating Performance

Output consistency hinges on precise engineering parameters:

- Screw L/D ratios averaging 40:1 ensure complete material plastification

- Variable-frequency drives maintaining torque accuracy within 0.5%

- Microprocessor-controlled heaters with 20-zone barrel temperature regulation

Recent innovations include laser-measured cutter blades maintaining 2-3 micron edge tolerances, directly impacting pellet geometry consistency. Material waste percentages have decreased from historical 8-12% to under 3.5% in premium systems.

Manufacturer Comparison Analysis

| Manufacturer | Output Range (kg/h) | Energy Efficiency | Waste Percentage | Automation Level |

|---|---|---|---|---|

| Coperion | 800-3,200 | 0.32 kWh/kg | 2.8% | Industry 4.0 |

| Milacron | 550-2,800 | 0.35 kWh/kg | 3.1% | Semi-Automated |

| KraussMaffei | 1,000-3,500 | 0.29 kWh/kg | 2.5% | Full IoT Integration |

| Leistritz | 700-2,500 | 0.31 kWh/kg | 2.9% | Industry 4.0 |

Data compiled from 2023 industry performance reports showing KraussMaffei systems achieving 15% higher output stability during 72-hour continuous production tests.

Industrial Applications with Documented Results

Pipe Profile Production: Turkish manufacturer Plastik Üretim doubled output to 2.8 tons/hour while reducing power consumption by 28% after installing a KraussMaffei extrusion pelletizing machine. Their ROI period measured 14 months.

Medical Grade PVC: Strict tolerance requirements in catheter production are met through precision pelletizers achieving ±0.05mm diameter consistency. German medtech firm MediPol reported 99.2% pellet uniformity using Coperion's ZS-EG platform.

Configuration Frameworks for Specialized Needs

Leading pvc pipe extrusion line manufacturers offer modular designs addressing unique requirements:

- Thermal Systems: Options range from standard oil heating to electromagnetic induction for rapid temperature changes (±20°C in 90 seconds)

- Cutting Modules: Centrifugal knife systems handling 3,000 cuts/minute versus underwater pelletizers for complex polymer blends

- Material Handling: Vacuum conveying configurations preventing moisture absorption during transfer

Thai manufacturer Siam Polytech customized a Milacron system with liquid cooling for transparent PVC production, achieving 99% optical clarity in final products.

Material Science Considerations

Optimal processing varies significantly across PVC formulations:

| PVC Type | Processing Temp (°C) | Screw Speed (RPM) | Die Pressure (bar) | Pellet Stability |

|---|---|---|---|---|

| Rigid PVC | 170-190 | 220-260 | 280-320 | High |

| Flexible PVC | 160-175 | 180-220 | 200-250 | Medium |

| CPVC | 190-210 | 240-280 | 300-350 | Very High |

Processing temperature adjustments must correspond with plasticizer content - formulations exceeding 40 PHR require barrel cooling to prevent degradation.

Advancements in Operational Efficiency Strategies

Industry leaders now implement predictive maintenance protocols that reduce unscheduled downtime by 65%. Vibration analysis sensors monitor gearbox health, while infrared thermography identifies developing hot spots in barrel zones.

Modern extrusion pelletizing machine interfaces incorporate machine learning algorithms that adjust parameters based on material viscosity readings. These systems have demonstrated 18% improvement in consistency during raw material batch transitions and maintain pellet dimensions within ±0.03mm tolerance through 500+ production hours.

(pvc pelletizing extrusion line)

FAQS on pvc pelletizing extrusion line

Q: What is the primary function of a PVC pelletizing extrusion line?

A: A PVC pelletizing extrusion line processes raw PVC materials into uniform pellets. It combines extrusion, cooling, and cutting mechanisms for efficient recycling or production. These pellets are used in manufacturing PVC pipes, sheets, and other products.

Q: How to choose reliable PVC pipe extrusion line manufacturers?

A: Prioritize manufacturers with certifications like ISO and proven industry experience. Evaluate their after-sales support, customization options, and client reviews. Partnering with established brands ensures consistent quality and technical expertise.

Q: What are the advantages of using an extrusion pelletizing machine?

A: Extrusion pelletizing machines streamline PVC waste into reusable pellets, reducing material waste. They ensure precise size control and high output efficiency. This process supports sustainable manufacturing and cost-effective production cycles.

Q: How often should a PVC pelletizing extrusion line be maintained?

A: Regular maintenance every 3-6 months is recommended, depending on usage intensity. Clean screws and barrels after each batch to prevent material degradation. Follow the manufacturer’s guidelines to avoid downtime and extend equipment life.

Q: Can PVC pipe extrusion line manufacturers provide customized solutions?

A: Yes, most manufacturers offer tailored designs for specific production needs. Customization may include throughput adjustments, pellet size variations, or integration with existing systems. Confirm technical support and testing services before finalizing orders.

-

Innovative Solutions in PVC Pipe Production LineNewsJul.18,2025

-

Innovative Solutions in Pipe Extrusion Production LineNewsJul.18,2025

-

Advanced Plastic Profile Extrusion SolutionsNewsJul.18,2025

-

PVC Profiles: The Future of Durable and Cost-Effective Construction SolutionsNewsJun.06,2025

-

PVC Pipe Extrusion LineNewsJun.06,2025

-

High-Quality Polyethylene Pipe Production LineNewsJun.06,2025

-

High-Performance Tube Production LineNewsJun.06,2025