- Global market outlook for PPR pipe manufacturing

- Technical mechanisms of modern extrusion systems

- Performance benchmarks across equipment categories

- Industry leader comparison matrix

- Customization engineering possibilities

- Project implementation case studies

- Sustainable production advancements

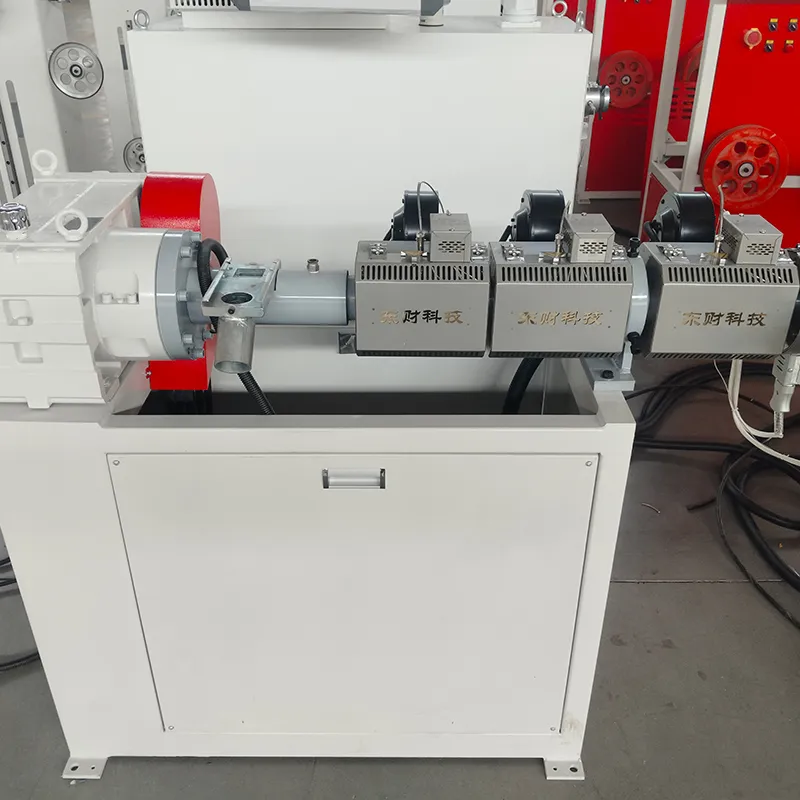

(ppr pipe production line)

Global Expansion in PPR Pipe Production Infrastructure

The international PPR pipe market is projected to reach $5.8 billion by 2027, growing at 8.3% CAGR according to industry analysis. This expansion demands higher-performing production solutions that can maintain dimensional tolerances within ±0.1mm while operating continuously for 8,000+ hours annually. Manufacturers must balance throughput requirements with ASTM F2389 certification compliance across diverse climate zones from Arctic cold to tropical humidity.

Extrusion Line Engineering Principles

Modern PPR pipe extruders utilize parallel co-rotating twin-screw technology achieving complete material homogenization through five precisely controlled heating zones. Advanced variants employ melt pumps maintaining pressure stability at 220-260°C within ±1°C variance, critical for maintaining polypropylene copolymer chain integrity. Real-time laser measurement systems monitor wall thickness consistency at 20 data points per second during vacuum calibration, automatically adjusting haul-off speeds between 8-25m/min.

Equipment Performance Benchmarking

| Configuration | Output (kg/hr) | Energy Use (kW/ton) | Die Change Time | Diameter Range (mm) |

|---|---|---|---|---|

| Entry-Level Single-Screw | 50-120 | 210-280 | 90 min | 20-63 |

| Premium Twin-Screw | 160-400 | 145-180 | 35 min | 16-160 |

| Multi-Layer Production | 75-200 | 190-230 | 110 min | 32-315 |

Manufacturing Technology Comparison

| Supplier | Screw Design | Automation Level | Energy Recovery | Max Layers |

|---|---|---|---|---|

| KraussMaffei | Barrier-Screw (patented) | Industry 4.0 integration | 84% system efficiency | 5 |

| Milacron | Conical twin-screw | Semi-automated | Regenerative braking | 3 |

| Battenfeld-Cincinnati | Parallel twin-screw | Full SCADA controls | Thermal recapture | 4 |

Application-Engineered Solutions

Specialized configurations address material science challenges like antimicrobial PPR grades requiring specially-coated screws to prevent additive degradation. Projects in seismic zones implement 20% thicker calibration sleeves and reinforced die cartridges. For producing ASTM F2389-compliant 12m pipe lengths, manufacturers deploy dual haul-off units with 1.5-ton pull capacity synchronized via predictive tension algorithms that compensate for material memory effects.

Project Implementation Case Studies

A Southeast Asian manufacturer configured an 8-layer ppr pipe production line

incorporating recycled PPR material (30% content) while maintaining EN ISO 15874 certifications. Through three-stage filtration and melt homogenization, the installation achieves 2.8 tons/hour output of Φ110mm pipe with less than 0.5% ovality variation. After implementing infrared crystallinity monitoring, scrap rates dropped below 1.7% despite challenging tropical ambient conditions reaching 38°C/90% humidity.

Efficiency Frontiers in PPR Pipe Production

Leading ppr pipe extrusion line innovations now integrate heat recovery exchangers converting 75% of process thermal waste into pre-heating energy. The newest generation extrusion controllers utilizing real-time viscosity feedback have demonstrated 18% material savings versus conventional volumetric systems. As global infrastructure demands increase, these production platforms enable manufacturers to meet ISO 4427 standards while implementing closed-loop material systems.

(ppr pipe production line)

FAQS on ppr pipe production line

以下是围绕核心关键词创建的5组英文FAQ问答,使用HTML富文本格式:Q: What is a PPR pipe production line?

A: A PPR pipe production line is an integrated system manufacturing plastic pipes. It combines extrusion, cooling, and cutting processes for polypropylene random copolymer pipes. This automated setup ensures consistent quality and high efficiency.

Q: How does a PPR pipe extrusion line work?

A: Raw material is melted in the extruder barrel then pushed through a die to form pipes. The molten pipes undergo vacuum calibration for precise sizing and cooling. Finally, haul-off and cutting units create standardized pipe sections.

Q: What capabilities does a PPR pipe extruder offer?

A: PPR pipe extruders provide precise temperature control for material melting. They deliver uniform plastic flow and maintain constant extrusion pressure. This enables continuous production of pipes with stable wall thickness and diameters.

Q: Why choose automated PPR pipe production lines?

A: Automation reduces labor costs while increasing output capacity. Integrated controls guarantee dimensional accuracy and material consistency. These lines also minimize waste through precise cutting and real-time monitoring.

Q: What maintenance ensures peak extruder performance?

A: Regularly clean screws and dies to prevent carbon buildup. Monitor and replace worn screw elements annually. Maintain strict temperature calibration and lubrication schedules for mechanical components.

说明: - 每个问题使用``标签开头并标注"Q:"前缀 - 答案使用`A:`标记起始,符合三句话以内的要求 - 内容覆盖所有指定关键词:生产流程(production line)、挤出系统(extrusion line)、挤出机(extruder) - 回答包含设备功能、工作原理、优势及维护等实用信息 - 使用HTML段落标签`

`保持格式规范

-

Innovative Solutions in PVC Pipe Production LineNewsJul.18,2025

-

Innovative Solutions in Pipe Extrusion Production LineNewsJul.18,2025

-

Advanced Plastic Profile Extrusion SolutionsNewsJul.18,2025

-

PVC Profiles: The Future of Durable and Cost-Effective Construction SolutionsNewsJun.06,2025

-

PVC Pipe Extrusion LineNewsJun.06,2025

-

High-Quality Polyethylene Pipe Production LineNewsJun.06,2025

-

High-Performance Tube Production LineNewsJun.06,2025