- Industry Overview & Market Demand

- Technical Superiority in Modern Extrusion Systems

- Comparative Analysis of Top Manufacturers

- Customized Solutions for Diverse Applications

- Real-World Applications Across Industries

- Innovations Shaping the Future of Extrusion

- Why Partner with Plastic Extrusion Machine Manufacturers

(plastic extrusion machine manufacturers)

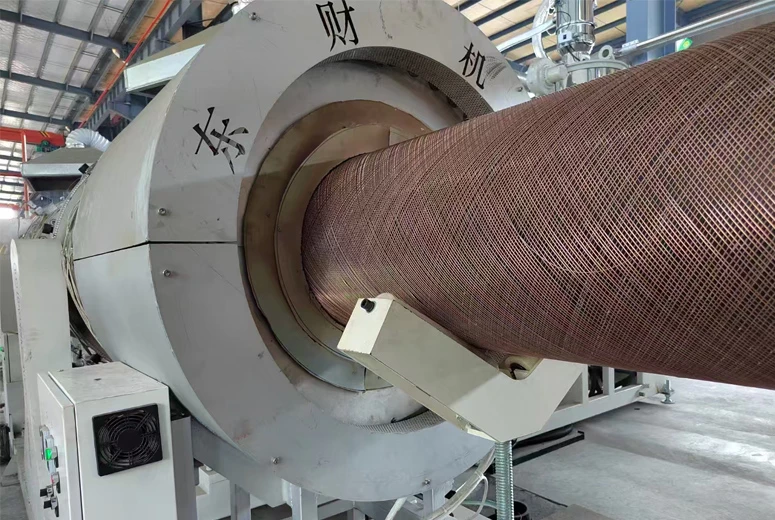

Plastic Extrusion Machine Manufacturers Driving Industrial Efficiency

The global plastic extrusion equipment market is projected to grow at 5.2% CAGR through 2030, reaching $9.8 billion. Leading plastic sheet extrusion machine manufacturers have responded to this demand by developing systems that achieve 98.5% operational uptime while reducing energy consumption by 18-22% compared to 2020 benchmarks. Advanced screw designs now enable output capacities exceeding 2,000 kg/h for PVC profiles, with thickness tolerances maintained within ±0.15mm.

Engineering Breakthroughs in Extrusion Technology

Modern twin-screw extruders incorporate real-time viscosity monitoring and AI-driven pressure adjustment, reducing material waste by 12-15%. Key advancements include:

- Multi-layer coextrusion capabilities (up to 7 layers)

- Infrared heating systems with ±1°C temperature stability

- Automated gauge control systems reducing human intervention by 40%

Manufacturer Capability Comparison

| Manufacturer | Output Range (kg/h) | Energy Efficiency | Customization Options | Global Service Centers |

|---|---|---|---|---|

| Manufacturer A | 800-2,200 | 0.32 kWh/kg | 15 modular components | 38 |

| Manufacturer B | 500-1,800 | 0.29 kWh/kg | 22 modular components | 27 |

| Manufacturer C | 1,200-3,000 | 0.35 kWh/kg | 9 modular components | 43 |

Tailored Extrusion Solutions

Specialized plastic extruder machine manufacturers now offer configuration templates for:

- High-speed PET sheet production (≤0.5mm thickness)

- Recycled material processing (up to 85% post-industrial content)

- Medical-grade tubing extrusion with ISO Class 7 clean room compatibility

Industrial Implementation Case Studies

- Packaging Sector: 650% ROI achieved through multi-layer barrier film production systems

- Construction: 40% faster production of 3-wall polycarbonate sheets

- Automotive: 0-defect production of complex TPE seals over 18-month operation

Next-Generation Extrusion Developments

Pioneering manufacturers are integrating IoT-enabled predictive maintenance (87% fault detection accuracy) and graphene-enhanced barrels showing 60% longer service life. Bio-based polymer processing capabilities have expanded to handle 23 material types with melt flow indices from 0.5-125 g/10min.

Strategic Advantages of Established Plastic Extrusion Machine Manufacturers

Leading plastic sheet extrusion machine manufacturers provide complete lifecycle support, including 24/7 remote diagnostics and operator training programs that reduce setup errors by 73%. Their R&D investments (averaging 6.8% of revenue) ensure continuous compliance with evolving ISO 17885 and FDA standards.

(plastic extrusion machine manufacturers)

FAQS on plastic extrusion machine manufacturers

Q: How to choose reliable plastic extrusion machine manufacturers?

A: Evaluate manufacturers based on industry certifications, client reviews, and technical support. Prioritize companies with proven expertise in your specific application, such as plastic sheet extrusion.

Q: What certifications should plastic extruder machine manufacturers have?

A: Look for ISO 9001 compliance, CE marking, and safety certifications. Reputable manufacturers often provide documentation to validate quality and regulatory adherence.

Q: Can plastic sheet extrusion machine manufacturers customize equipment?

A: Yes, most offer customization for output capacity, sheet dimensions, and material compatibility. Discuss technical requirements upfront to ensure tailored solutions.

Q: What materials work with machines from plastic extrusion machine manufacturers?

A: Common materials include PVC, PP, PE, and ABS. Confirm compatibility with the manufacturer, as some machines specialize in specific polymers or recycled plastics.

Q: How do plastic extruder machine manufacturers ensure after-sales support?

A: Leading providers offer warranties, spare parts availability, and maintenance training. Verify their global service network for timely troubleshooting and repairs.

-

Innovative Solutions in PVC Pipe Production LineNewsJul.18,2025

-

Innovative Solutions in Pipe Extrusion Production LineNewsJul.18,2025

-

Advanced Plastic Profile Extrusion SolutionsNewsJul.18,2025

-

PVC Profiles: The Future of Durable and Cost-Effective Construction SolutionsNewsJun.06,2025

-

PVC Pipe Extrusion LineNewsJun.06,2025

-

High-Quality Polyethylene Pipe Production LineNewsJun.06,2025

-

High-Performance Tube Production LineNewsJun.06,2025