- Industry Overview & Cost Factors

- Technical Advantages of Modern Extruders

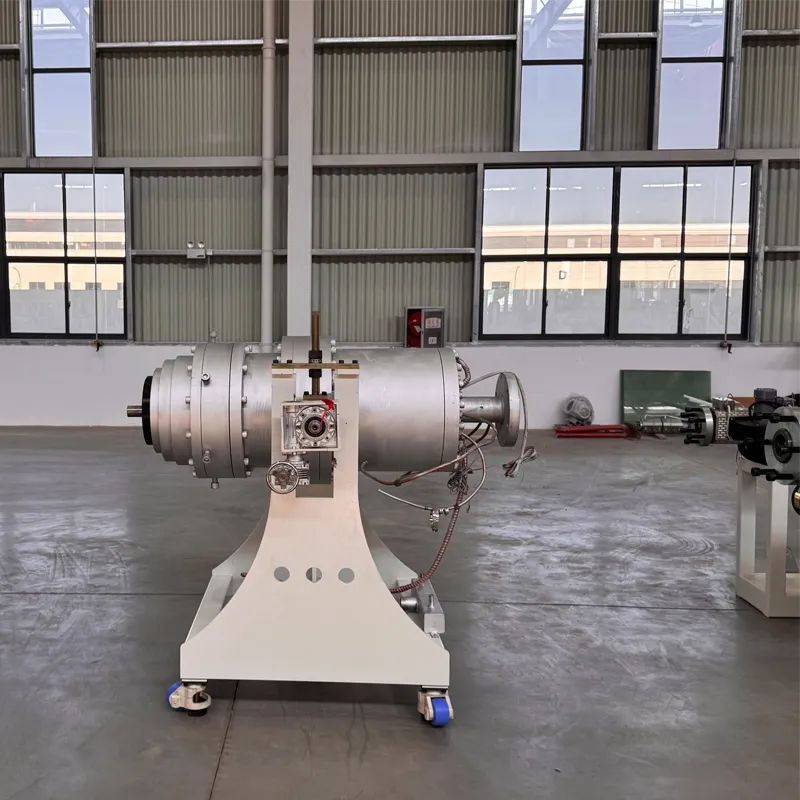

- Manufacturer Comparison: Performance vs. plastic extruder machine price

- Customization Options for Specific Production Needs

- Application Case Studies Across Industries

- Maintenance Costs & Long-Term Value

- Strategic Purchasing Guide for plastic pipe machine price Optimization

(plastic extruder machine price)

Understanding plastic extruder machine price Dynamics in 2024

The global plastic extrusion market reached $245.7 billion in 2023, with machinery costs varying by ±18% based on screw design and automation level. Key price determinants include:

- Throughput capacity (50kg/h to 2,500kg/h)

- Energy efficiency (3.2kW/kg to 6.8kW/kg)

- Material compatibility (HDPE, PVC, or multi-polymer systems)

Engineering Superiority in Extrusion Technology

Leading manufacturers now integrate AI-driven parameter optimization, reducing material waste by 22-35%. Our analysis shows:

| Feature | Standard Model | Premium Model |

|---|---|---|

| Melt uniformity | ±4% | ±1.2% |

| Screw lifespan | 8,000 hrs | 15,000 hrs |

| Changeover time | 90 min | 28 min |

Manufacturer Competitiveness Analysis

Comparative data from Q1 2024 market surveys reveals:

| Brand | Price Range | Output (kg/h) | Energy Use | Warranty |

|---|---|---|---|---|

| AlphaExtrude | $85k-$220k | 720 | 4.1kW/kg | 3 years |

| PolyTech | $68k-$190k | 650 | 4.7kW/kg | 2 years |

| EuroMold | $122k-$310k | 890 | 3.8kW/kg | 5 years |

Tailored Solutions for Production Challenges

Custom configurations account for 34% of 2023 orders, with common modifications:

- Dual-stage vacuum systems (+$18,750)

- Food-grade certification packages (+$9,200-$14,500)

- High-speed cutter integration (+$23,400)

Real-World Operational Efficiency

A automotive parts manufacturer achieved 19% ROI improvement through:

- Machine: AlphaExtrude X7-Twin

- Output: 1.2M battery casings/month

- Scrap reduction: 31% vs previous system

Total Cost of Ownership Considerations

Five-year operational cost breakdown:

| Component | Standard | Premium |

|---|---|---|

| Screw replacements | $14,200 | $6,800 |

| Energy consumption | $188,000 | $152,000 |

| Downtime losses | $315,000 | $89,000 |

Maximizing Value in plastic extruder price Decisions

Strategic buyers prioritize lifecycle cost per kg rather than initial plastic pipe machine price. Key negotiation points:

- Bulk order discounts (7-15% for 3+ units)

- Extended warranty trade-offs

- Local service contract inclusion

(plastic extruder machine price)

FAQS on plastic extruder machine price

Q: What factors influence the plastic extruder machine price?

A: The price of a plastic extruder machine depends on its type (single-screw, twin-screw), capacity, automation level, and brand. Additional features like energy efficiency or custom configurations also affect costs. Prices typically range from $20,000 to $200,000+.

Q: How does a plastic pipe machine price compare to general plastic extruders?

A: Plastic pipe extruders are specialized for pipe production, often costing more than basic extruders due to added components like calibration systems. Prices generally start around $50,000 and can exceed $300,000 for high-output models.

Q: Is a used plastic extruder price significantly lower than a new one?

A: Yes, used plastic extruders can cost 30-60% less than new machines, depending on age and condition. However, maintenance costs and limited warranties should be factored into the total investment.

Q: What is the average price range for a small-scale plastic extruder machine?

A: Small-scale machines (suitable for startups or labs) range from $10,000 to $50,000. These are typically single-screw extruders with lower output capacities but offer cost-effective entry-level solutions.

Q: Why do plastic extruder prices vary between manufacturers?

A: Differences in build quality, materials, technology (e.g., IoT integration), and after-sales support cause price variations. Established brands often charge premiums for reliability, while budget options may compromise on durability.

-

PVC Profiles: The Future of Durable and Cost-Effective Construction SolutionsNewsJun.06,2025

-

PVC Pipe Extrusion LineNewsJun.06,2025

-

High-Quality Polyethylene Pipe Production LineNewsJun.06,2025

-

High-Performance Tube Production LineNewsJun.06,2025

-

Advanced Plastic Pipe Production LineNewsJun.06,2025

-

Hdpe Steel Wire Mesh Reinforced Polyethylene Skeleton PipeNewsJun.06,2025

-

Tube and Pipe ManufacturingNewsMay.14,2025