- Fundamentals of Modern Sheet Extrusion Systems

- Engineering Advantages in Contemporary Designs

- Manufacturer Comparison Matrix

- Application-Specific Configuration Options

- Industry Implementation Case Studies

- Operational Efficiency and ROI Analysis

- Future-Proofing Your Production Capabilities

(pvc sheet extrusion machine)

Fundamentals of Modern PVC Sheet Extrusion Technology

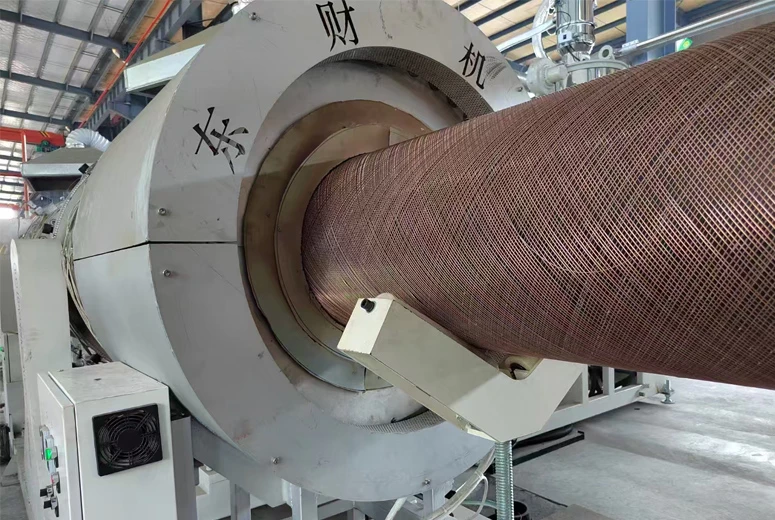

Contemporary PVC sheet extrusion machinery transforms raw compound into uniform thickness sheets through continuous thermo-mechanical processing. The extrusion line comprises five integrated systems: precision feeding unit, twin-screw extrusion barrel with temperature-controlled zones, planar die assembly, three-stage calendering/cooling stack, and synchronized haul-off/cutting station. Modern systems process 800-2,200 kg/hour of rigid PVC compound with thickness consistency achieving ±0.05mm tolerance across 1-12mm sheet ranges.

Material science advancements enable processing specialized formulations including anti-static compounds (10⁶-10⁸ Ω), UV-stabilized grades (withstand 15+ years outdoor exposure), and fire-retardant variants (UL94 V-0 certification). Recent innovations incorporate infrared thickness monitoring systems that automatically adjust die lip positions every 2.7 seconds, maintaining dimensional accuracy exceeding 98.5% across production runs. This technological foundation enables manufacturers to produce specialist sheet products meeting exacting international standards including ISO 9001, CE Mark, and NSF/ANSI 61 certifications.

Engineering Advantages in Contemporary Designs

Leading extrusion lines now incorporate patented screw designs like barrier-flight geometries that increase melting efficiency by 28% while reducing specific energy consumption to 0.33-0.38 kWh/kg. Dual-stage vacuum degassing eliminates volatiles more effectively than conventional systems, achieving residual moisture content below 0.12% in finished sheets. Temperature control innovations maintain ±0.8°C stability across all barrel zones using microprocessor-controlled ceramic heaters.

Modern machines feature modular construction allowing quick-changeover between product formats in under 22 minutes. High-precision gear pumps ensure ±0.7% output consistency during 24/7 operation, critical for maintaining optical properties in transparent applications. The latest designs incorporate IoT sensors that monitor 37+ operational parameters in real-time, enabling predictive maintenance that reduces unplanned downtime to under 3% annually.

Leading Equipment Manufacturers Comparison

| Manufacturer | Output Capacity (kg/h) | Energy Rating | Thickness Range (mm) | Smart Features | Standard Warranty |

|---|---|---|---|---|---|

| Company Alpha | 1,200-2,200 | 0.34 kWh/kg | 1-15 | AI predictive maintenance | 3 years |

| EuroTech Extrusion | 850-1,800 | 0.37 kWh/kg | 0.8-12 | Automated die lip adjustment | 2 years |

| PrecisionLine Systems | 900-1,900 | 0.41 kWh/kg | 1-10 | Real-time quality analytics | 2 years |

| Global Machinery Inc | 800-1,600 | 0.45 kWh/kg | 1.5-12 | Cloud performance monitoring | 18 months |

Customized Configuration Solutions

Premium suppliers offer factory-configured systems tailored to specific production requirements. Options include dual-calender arrangements enabling instant transition between matte and gloss finishes without line stoppage, or integrated inline embossing units producing textured surfaces at 12-18 meters/minute. Medical-grade configurations feature ISO Class 7 cleanroom housings and certified metallurgy contact surfaces.

For specialized applications, manufacturers provide modular add-ons like co-extrusion adapters applying protective PMMA layers simultaneously with PVC substrates. Automotive supply installations often incorporate robotic stacking systems synchronized with production speed. Custom thermal profiles allow processing CPVC formulations requiring higher melt temperatures (215-230°C) alongside standard PVC compounds. These tailored solutions reduce secondary processing steps by approximately 35%.

Industry Implementation Case Studies

Construction Materials Producer (Spain): Installation of a twin-screw rigid sheet extrusion line expanded production capacity by 240% while reducing energy consumption 28% through heat recovery systems. The €1.8 million investment achieved payback within 13 months after enabling round-the-clock production of 20,000 linear meters/day of building panels.

Medical Equipment Manufacturer (USA): Implementation of a medical-grade line with automatic thickness correction resulted in FDA-approved production of radiolucent surgical trays. The system reduced material waste to 0.8% from previous 6.2% while achieving sustained production speeds of 9 meters/minute with ±0.03mm thickness accuracy.

Operational Efficiency Analysis

Operational economics demonstrate 65-75% production cost determined by raw materials, highlighting the significance of extrusion efficiency. Advanced twin-screw designs with L/D ratios from 36:1 to 44:1 achieve 97% material utilization versus 88-91% in conventional systems. Automatic recipe storage allows immediate change between formulations in 90 seconds without purging compound losses.

Modern energy recovery systems capture up to 55% of dissipated thermal energy for pre-heating incoming materials. Combined with premium AC vector motors that reduce power consumption 18-22% versus traditional drives, these innovations contribute to total operating cost reductions of €27,000-€52,000 annually per production line based on 6,000 operating hours. Comprehensive IoT connectivity minimizes technician intervention while providing production analytics unavailable in legacy equipment.

Future-Proof Production Capabilities with PVC Sheet Extrusion Machinery

Investing in contemporary PVC sheet extrusion technology establishes a foundation for manufacturing excellence well into the next decade. Forward-looking operations incorporate Industry 4.0 capabilities into their extrusion lines for complete production visibility. These intelligent systems automatically log 48+ quality parameters per minute while maintaining a continuous production uptime exceeding 95% in demanding industrial environments.

Scalability remains paramount in new installations. Premium extrusion machine suppliers design systems with capacity headroom enabling potential future 30-45% output increases through component upgrades rather than complete replacements. As global standards evolve, modular architecture permits straightforward integration of emerging technologies. These future-ready manufacturing platforms ensure compliance with increasingly stringent sustainability regulations while maintaining cost leadership.

(pvc sheet extrusion machine)

FAQS on pvc sheet extrusion machine

Q: What is a PVC sheet extrusion machine used for?

A: A PVC sheet extrusion machine manufactures continuous PVC sheets through melting, shaping, and cooling processes. It's essential for producing rigid or semi-rigid PVC sheets used in construction, packaging, and signage. The system precisely controls thickness and width for consistent output.

Q: How does a PVC rigid sheet extrusion line work?

A: PVC granules are fed into an extruder where heat and pressure melt the material. The molten PVC is then forced through a flat die to form a continuous sheet, which is cooled and calibrated by rollers. Finally, it's cut to size or coiled for packaging.

Q: What industries require PVC sheet extrusion machines?

A: Key users include the construction sector for producing panels and partitions, packaging manufacturers for blister packs and clamshells, and advertising companies for signage boards. Automotive and medical industries also utilize these machines for specialized components.

Q: What are the main components of a PVC sheet extrusion line?

A: Core components include the hopper feeder, screw extruder, flat sheet die, three-roll calendering system, and cooling/cutting stations. Advanced lines integrate PLC controls for thickness regulation and automated stacking systems. Auxiliary equipment like chillers and grinders support continuous operation.

Q: How to choose between single vs twin-screw extruders for PVC sheet production?

A: Single-screw extruders are cost-effective for standard rigid PVC formulations at lower outputs. Twin-screw machines provide superior mixing for filled compounds or high-volume production, offering better thermal control and output stability. Selection depends on material complexity and required production capacity.

-

Innovative Solutions in PVC Pipe Production LineNewsJul.18,2025

-

Innovative Solutions in Pipe Extrusion Production LineNewsJul.18,2025

-

Advanced Plastic Profile Extrusion SolutionsNewsJul.18,2025

-

PVC Profiles: The Future of Durable and Cost-Effective Construction SolutionsNewsJun.06,2025

-

PVC Pipe Extrusion LineNewsJun.06,2025

-

High-Quality Polyethylene Pipe Production LineNewsJun.06,2025

-

High-Performance Tube Production LineNewsJun.06,2025