- Introduction to PVC Profile Extrusion Line Technology

- Market Growth and Statistical Overview

- Technical Advantages of Modern Extrusion Lines

- Comparative Analysis of Leading Manufacturers

- Customization Solutions for Diverse Applications

- Real-world Application Cases

- Conclusion: The Bright Future of PVC Profile Extrusion Line Industry

(pvc profile extrusion line)

Introduction to the Advancements in PVC Profile Extrusion Line

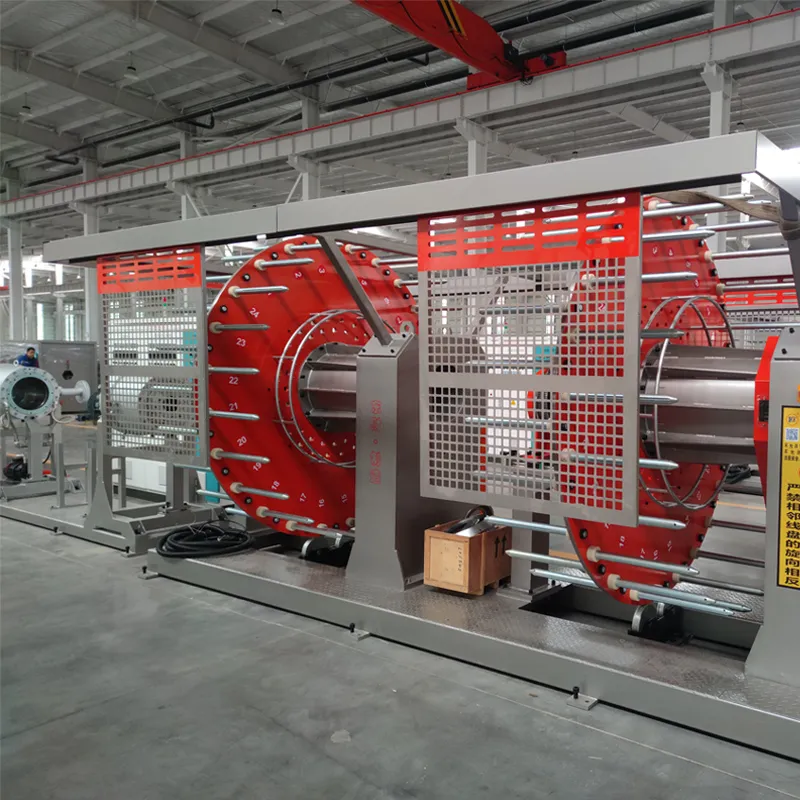

The evolution of pvc profile extrusion line

technology marks a significant leap in the plastics manufacturing industry. Initially designed for efficient production of high-volume PVC sections, these state-of-the-art systems now set the standards for productivity, quality, and sustainability. The pvc window profile extrusion line, a specialized segment, enables manufacturers to meet the growing demand for durable and energy-efficient building materials. Over the years, continuous innovations in pvc profile production line engineering have resulted in machinery capable of complex shapes, high throughput rates, and reduced operational costs. This blog explores the strategic imperatives, technical functionalities, and market opportunities surrounding this dynamic manufacturing ecosystem.

Market Growth and Statistical Overview

The global PVC profiles market has witnessed robust expansion over the past decade. According to recent industry analysis, the market size was valued at USD 2.6 billion in 2022 and is expected to reach USD 4.1 billion by 2028, registering a compound annual growth rate (CAGR) of approximately 8.1%. This growth is propelled by the construction sector's increasing adoption of uPVC windows and doors, as well as infrastructural developments in emerging economies. It is worth noting that the Asia-Pacific region dominates the landscape, accounting for over 45% of global demand. The shift toward sustainable and energy-efficient solutions further accelerates the deployment of modern extrusion lines, making investment in high-tech machinery a crucial factor for manufacturers seeking a competitive edge.

Technical Advantages of Modern Extrusion Lines

Technological innovation has dramatically improved the performance and adaptability of pvc profile extrusion equipment. Modern systems are characterized by:

- Advanced twin-screw extruders for exceptional homogenization and efficient plasticization

- Automated control systems (PLC/HMI interfaces) for streamlined operations and real-time monitoring

- High-precision calibration tables for exact dimensional tolerances

- Energy-saving drives and optimized heat zones to reduce power consumption by up to 30%

- Flexible tooling configurations supporting personalized product geometries

Comparative Analysis of Leading Manufacturers

The market for pvc profile production line machinery features several global and regional players, each offering distinct strengths. The following table presents a side-by-side technical and performance review of leading manufacturers based on publicly available data and customer reports:

| Manufacturer | Max Output (kg/h) | Automation Level | Energy Efficiency | Warranty (Years) | Customization Possibility |

|---|---|---|---|---|---|

| KraussMaffei (Germany) | 400 | Full PLC/HMI | Excellent (28% savings) | 2 | High |

| Cincinnati Milacron (USA) | 360 | Full PLC | Very Good (24% savings) | 2 | Medium |

| Qingdao De Er Cheng Machinery (China) | 320 | Semi-automatic | Good (19% savings) | 1 | High |

| Battenfeld-Cincinnati (Austria) | 380 | Full PLC/HMI | Excellent (27% savings) | 2 | Medium |

| AMUT (Italy) | 340 | Semi-automatic | Good (21% savings) | 1 | High |

By assessing these metrics, prospective buyers can identify the best-fit extrusion system based on production volume requirements, automation integration, and return on investment.

Customization Solutions for Diverse Applications

As architectural and industrial designs become more varied, the demand for customized extrusion products has soared. Leading manufacturers are responding by offering modular die configurations, adjustable vacuum calibrators, and rapid tooling changeover features. This enables them to deliver both standard and bespoke pvc window profile extrusion lines tailored for niche market needs, such as complex co-extruded layers, acoustic or thermal insulation properties, and special surface treatments (e.g., woodgrain or metallic finishes).

The ability to integrate in-line lamination or gasket insertion processes further enhances system flexibility. For OEMs and fabricators, this means they can quickly adapt their manufacturing to evolving customer requirements, facilitating short-run production without sacrificing operational efficiency. Advanced CAD/CAM simulations and prototyping services ensure new profiles are tested thoroughly before mass rollout, minimizing risk while maximizing competitiveness.

Real-world Application Cases

The versatility of modern pvc profile extrusion line machinery underpins success across a breadth of sectors. In the construction industry, for example, a leading Eastern European window manufacturer reported a 35% increase in yearly output and a 22% reduction in defect rates after upgrading to a fully automated system. Meanwhile, an Egyptian furniture producer leveraged customized dies to develop lightweight yet robust assemblies for modular housing, facilitating growth into new export markets and realizing a payback period of just 18 months.

Utilities and infrastructure sectors are deploying advanced profile lines for cable management systems, protective trunking, and customized technical profiles that meet strict regulatory criteria. In a recent survey, over 68% of manufacturers indicated that the adoption of high-efficiency extrusion lines directly contributed to improved sustainability ratings and access to environmentally conscious clientele. By optimizing line speeds, energy usage, and raw material formulations, companies achieve not only operational excellence but also bolster their corporate social responsibility credentials.

Conclusion: The Bright Future of PVC Profile Extrusion Line Industry

The pvc profile extrusion line segment stands poised for continual innovation and expansion. As global demand for sustainable, high-performance building products accelerates, the adoption of cutting-edge technology will be critical for manufacturers and stakeholders alike. Investments in automation, customization, and smart data integration ensure that the pvc profile production line of tomorrow can efficiently meet both mass and specialized needs. With strategic planning and attention to evolving market trends, industry leaders can secure stronger margins and establish enduring competitive advantages in the years to come.

(pvc profile extrusion line)

FAQS on pvc profile extrusion line

Q: What is a PVC profile extrusion line?

A: A PVC profile extrusion line is a manufacturing system designed to produce various PVC profiles, such as window or door frames. It melts and shapes raw PVC materials into continuous, custom profiles. This line ensures high precision and consistent quality in profile production.Q: What applications are supported by a PVC window profile extrusion line?

A: A PVC window profile extrusion line is mainly used for producing window and door frames. It can manufacture profiles in different shapes and sizes according to customer requirements. These profiles are widely used in residential and commercial buildings.Q: What are the main components of a PVC profile production line?

A: The main components include a conical twin-screw extruder, vacuum calibration table, haul-off unit, cutter, and stacker. Each part plays a crucial role in shaping, cooling, and cutting the profile. Together, they enable efficient, automated mass production of PVC profiles.Q: How can I ensure quality in products made by a PVC profile extrusion line?

A: Regular maintenance and using high-quality raw materials are key to ensuring product quality. Additionally, advanced temperature and extrusion speed controls help maintain consistent output. Well-trained operators further reduce the risk of defects.Q: What are the advantages of using a PVC profile extrusion line for manufacturers?

A: PVC profile extrusion lines offer high productivity, energy efficiency, and precise control over dimensions. They support flexible design options and fast changeovers for different profiles. This results in reduced labor costs and increased operational efficiency.-

PVC Profiles: The Future of Durable and Cost-Effective Construction SolutionsNewsJun.06,2025

-

PVC Pipe Extrusion LineNewsJun.06,2025

-

High-Quality Polyethylene Pipe Production LineNewsJun.06,2025

-

High-Performance Tube Production LineNewsJun.06,2025

-

Advanced Plastic Pipe Production LineNewsJun.06,2025

-

Hdpe Steel Wire Mesh Reinforced Polyethylene Skeleton PipeNewsJun.06,2025

-

Tube and Pipe ManufacturingNewsMay.14,2025