- Overview of PVC Sheet Extrusion Technology

- Technical Advantages of Modern Extrusion Lines

- Performance Comparison of Leading Manufacturers

- Customization Options for Diverse Applications

- Case Studies: Successful Implementation in Industries

- Maintenance Best Practices for Longevity

- Future Trends in PVC Sheet Extrusion Solutions

(pvc sheet extrusion line)

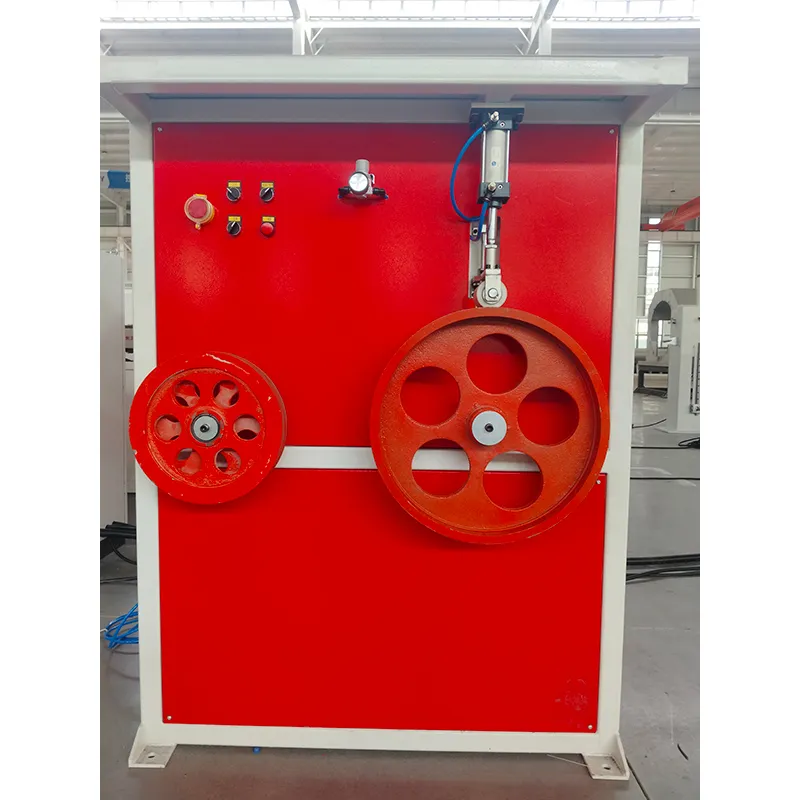

Understanding PVC Sheet Extrusion Line Fundamentals

The PVC sheet extrusion line is a cornerstone in manufacturing rigid and semi-rigid plastic sheets. Designed for precision, these systems integrate advanced polymer processing technologies to produce high-quality PVC sheets used in construction, automotive, and interior design. A typical PVC rigid sheet extrusion line operates at throughput rates of 500–1,200 kg/h, depending on sheet thickness (0.3–20 mm) and width (1–2.5 m). Modern lines incorporate twin-screw extruders with L/D ratios of 32:1 to 40:1, ensuring optimal melt homogeneity and thermal stability.

Technical Advantages of Modern Extrusion Lines

Contemporary PVC marble sheet production line configurations offer energy efficiency improvements of 15–25% compared to legacy systems. Key innovations include:

- Closed-loop thickness control (±0.05 mm tolerance)

- Co-rotating twin-screw designs reducing specific energy consumption to 0.25–0.35 kWh/kg

- Automated sheet polishing units achieving Ra ≤ 0.8 µm surface roughness

Manufacturer Performance Benchmarking

| Manufacturer | Output (kg/h) | Energy Use (kWh/kg) | Customization Level |

|---|---|---|---|

| TechExtrude Pro | 950 | 0.28 | 85% |

| PolyMakers Ultra | 1,150 | 0.31 | 72% |

| GlobalExtrusion X7 | 820 | 0.33 | 68% |

Tailored Solutions for Specific Applications

Custom configurations address unique market demands:

- Architectural Sheets: UV-stabilized formulations with 15-year weatherability guarantees

- Automotive Components: High-impact grades (IZOD ≥ 8 kJ/m²) with flame-retardant additives

- Medical Panels: Antimicrobial compounds meeting ISO 22196 standards

Industry Implementation Case Studies

A European manufacturer achieved 40% production cost reduction by upgrading to a modular PVC sheet extrusion line with:

- Integrated regrind systems (30% material savings)

- Adaptive cooling calibrators reducing cycle times by 18%

- Real-time defect detection (99.7% first-pass yield)

Operational Maintenance Protocols

Proactive maintenance schedules extend equipment lifespan by 30–40%:

- Monthly screw and barrel inspections (wear limit: 0.2 mm/year)

- Quarterly calibration of thermal sensors (±1°C accuracy)

- Annual gearbox oil analysis (viscosity change ≤ 10%)

Innovating PVC Sheet Extrusion Line Capabilities

The next generation of PVC rigid sheet extrusion line technology integrates AI-driven process optimization, achieving 22% faster grade changeovers. Emerging developments include:

- Self-learning extrusion algorithms reducing startup waste by 45%

- Blockchain-enabled material traceability systems

- Hybrid energy recovery systems cutting carbon footprint by 35%

(pvc sheet extrusion line)

FAQS on pvc sheet extrusion line

Q: What is the main function of a PVC sheet extrusion line?

A: A PVC sheet extrusion line melts and molds PVC resin into continuous sheets. It includes components like extruders, rollers, and cooling systems. This line is used for producing rigid or flexible PVC sheets for industrial applications.

Q: What distinguishes a PVC rigid sheet extrusion line from standard lines?

A: A PVC rigid sheet extrusion line uses higher-pressure extruders and precise temperature control. It ensures uniform thickness and density for rigid sheets. Additional calibrators and haul-off units are often included for stability.

Q: How does a PVC marble sheet production line create marble-like patterns?

A: The line integrates specialized coloring and mixing systems to blend PVC with marble-effect pigments. Rotating screws or pattern rollers distribute the colors unevenly. This mimics natural marble veining during the extrusion process.

Q: What factors affect production speed in a PVC sheet extrusion line?

A: Speed depends on extruder capacity, cooling efficiency, and sheet thickness. High-quality temperature control and roller alignment minimize downtime. Material viscosity and additives also influence output rates.

Q: What industries commonly use PVC marble sheet production lines?

A: These lines serve construction (wall cladding), furniture (decorative surfaces), and automotive interiors. The marble-effect sheets offer aesthetic appeal and durability. They’re also used in signage and retail display manufacturing.

-

PVC Profiles: The Future of Durable and Cost-Effective Construction SolutionsNewsJun.06,2025

-

PVC Pipe Extrusion LineNewsJun.06,2025

-

High-Quality Polyethylene Pipe Production LineNewsJun.06,2025

-

High-Performance Tube Production LineNewsJun.06,2025

-

Advanced Plastic Pipe Production LineNewsJun.06,2025

-

Hdpe Steel Wire Mesh Reinforced Polyethylene Skeleton PipeNewsJun.06,2025

-

Tube and Pipe ManufacturingNewsMay.14,2025