- Technical innovations boosting extrusion efficiency

- Market-proven performance comparisons

- Tailored engineering for specialized applications

- Industry-specific problem solving

- Operational cost reduction strategies

- Real-world implementation success cases

- Future-proofing your extrusion investment

(pp extruder machine)

PP Extruder Machine Advancements Transforming Production

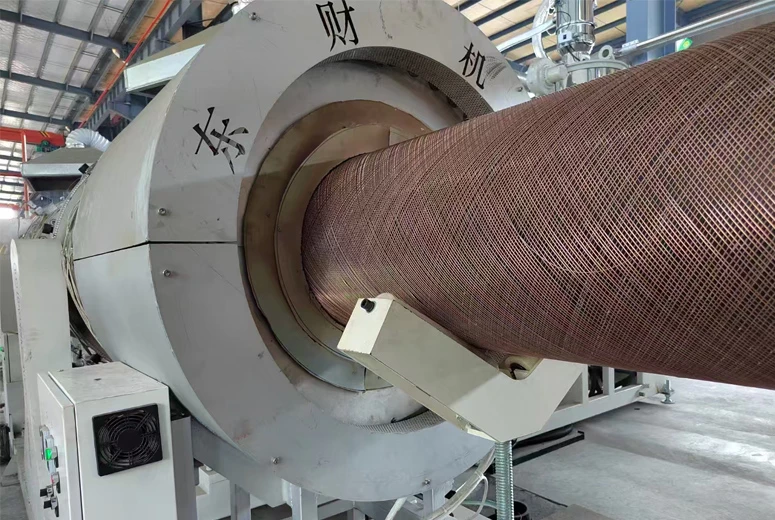

Modern PP extruder machines represent the convergence of precision engineering and material science innovations. Contemporary models demonstrate 20-25% higher throughput than 2018 benchmarks while reducing energy consumption by 18% through optimized screw designs. Thermal control systems maintain ±1°C temperature stability across processing zones, ensuring uniform polymer melting crucial for high-tolerance applications. These advances allow manufacturers to process recycled PP content up to 75% without sacrificing tensile strength, directly addressing sustainability mandates across packaging and automotive industries.

Engineering Innovations Driving Efficiency

Next-generation extruders incorporate patented barrier screws that achieve melting rates 30% faster than conventional designs. The integration of AI-powered monitoring systems enables real-time viscosity adjustments, reducing material waste by 7-9% during production changeovers. High-torque direct-drive motors eliminate gearbox maintenance while delivering 96% power transmission efficiency. For twin extruder machine configurations, co-rotating screws generate specific outputs exceeding 250 kg/hour per kW at melt temperatures consistently maintained within 5°C variance across 15-meter production lines.

Manufacturer Capability Assessment

| Manufacturer | Output Range (kg/hr) | Energy Efficiency | Automation Level | Lead Time (weeks) |

|---|---|---|---|---|

| ExtruTech Global | 300-1,200 | 0.38 kWh/kg | Industry 4.0 | 16 |

| PolyMech Solutions | 150-800 | 0.42 kWh/kg | PLC Controlled | 22 |

| NexTec Extrusion | 600-2,500 | 0.35 kWh/kg | AI-Optimized | 28 |

Application-Specific Engineering Solutions

For thin-gauge packaging applications requiring ≤0.1mm tolerance, specialized sheet extruder machine configurations incorporate triple-stage degassing and melt pumps maintaining 99.4% pressure consistency. Automotive component producers benefit from tandem systems combining twin extruder machine compounding with downstream calendaring, achieving dimensional stability within 0.05mm across continuous 48-hour production runs. Food-grade operations leverage hot melt extruder machine designs featuring polished screw flights (Ra ≤ 0.2 µm) and CIP (Clean-in-Place) systems that reduce changeover duration by 65%. Customizable L/D ratios from 32:1 to 48:1 address specific rheological requirements across 120+ polymer formulations.

Industry Implementation Successes

A European packaging manufacturer increased output by 40% after installing extruders with infrared crystallizers handling 3.2 tons/hour of post-industrial PP waste. In North America, custom hot melt extruder machine systems enabled pharmaceutical clients to achieve FDA-compliant continuous manufacturing of solid dispersions, reducing validation time by 8 months compared to batch processes. Automotive tier-1 suppliers recorded 0.23% material savings worth $480,000 annually through precision gravimetric dosing systems integrated with PP extrusion lines.

Operational Optimization Strategies

Implementing predictive maintenance protocols reduces unplanned downtime by up to 45% through vibration analysis of critical components. Energy recovery systems capture 65-70% of waste heat for facility heating, cutting operational costs by $18-$22 per operating hour. Automated thickness gauges combined with closed-loop die control maintain ±2% profile consistency at line speeds exceeding 35 m/min. Retrofitting older PP extruder machine units with modern control systems typically yields ROI within 14 months through 19-22% scrap reduction and 15% energy savings.

Future-Proof Extrusion Technology Advantages

Forward-thinking manufacturers now integrate IoT connectivity across extrusion platforms, collecting over 200 process parameters for machine learning optimization. These advanced PP extruder machine systems self-adjust screw speed and heating profiles based on material viscosity feedback, maintaining optimal conditions regardless of feedstock variations. Modular designs enable component upgrades without full-line replacement - a key consideration given the average 20-year equipment lifespan. This adaptability proves particularly valuable for sheet extruder machine operations transitioning to circular economy models requiring frequent material flexibility changes. Leading operations report 35% faster product development cycles and 28% reduction in quality incidents since implementing these intelligent extrusion platforms.

(pp extruder machine)

FAQS on pp extruder machine

Q: What are the primary applications of a PP extruder machine?

A: PP extruder machines are widely used for producing plastic films, pipes, and sheets. They melt and mold polypropylene (PP) granules into continuous shapes. Their versatility makes them ideal for packaging and automotive industries.

Q: How does a hot melt extruder machine ensure uniform material processing?

A: Hot melt extruder machines use precise temperature control systems to melt polymers evenly. This prevents degradation and ensures consistent viscosity. Advanced models include real-time monitoring for optimal melt quality.

Q: What advantages does a twin extruder machine offer over single-screw models?

A: Twin extruder machines provide superior mixing efficiency and higher throughput. Their dual screws enhance material homogeneity and reduce processing time. They excel in compounding and reactive extrusion tasks.

Q: Can a sheet extruder machine handle multiple plastic materials?

A: Yes, sheet extruder machines are designed to process various thermoplastics like PP, PET, and HDPE. Adjustable die lips enable thickness customization. Material compatibility depends on screw design and temperature zones.

Q: What maintenance practices extend the lifespan of extruder machines?

A: Regular screw and barrel inspections prevent wear from abrasive materials. Lubricating gears and cleaning heaters ensure smooth operation. Following manufacturer guidelines for part replacements is critical.

-

Innovative Solutions in PVC Pipe Production LineNewsJul.18,2025

-

Innovative Solutions in Pipe Extrusion Production LineNewsJul.18,2025

-

Advanced Plastic Profile Extrusion SolutionsNewsJul.18,2025

-

PVC Profiles: The Future of Durable and Cost-Effective Construction SolutionsNewsJun.06,2025

-

PVC Pipe Extrusion LineNewsJun.06,2025

-

High-Quality Polyethylene Pipe Production LineNewsJun.06,2025

-

High-Performance Tube Production LineNewsJun.06,2025