- Fundamentals of HDPE extrusion technology and material properties

- Cutting-edge technical specifications of modern extruders

- Comparative analysis of industry-leading manufacturers

- Custom engineering solutions for specialized applications

- Performance data from industrial implementation case studies

- Investment analysis and operational cost considerations

- Future technological advancements in extrusion systems

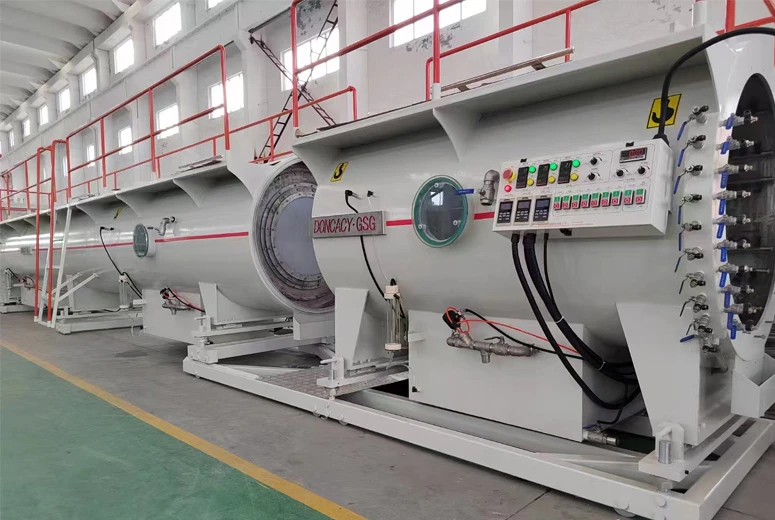

(hdpe extruder)

Understanding HDPE Extruder Technology Fundamentals

High-Density Polyethylene extrusion requires precise molecular alignment to achieve optimal pipe strength. Modern hdpe pipe extruder systems maintain barrel temperatures within ±1°C tolerance through PID-controlled heating zones, preventing crystalline inconsistencies during polymerization. The material's melt flow index (MFI) between 0.2-0.4 g/10min demands specialized screw designs with compression ratios of 3:1 to 4:1 to prevent degradation while maintaining production rates of 500-2000 kg/hour. Barrier screws with Maddock mixing elements ensure homogeneous melting, reducing material waste by 18-22% compared to conventional designs.

Technical Specifications and Performance Capabilities

Contemporary hdpe extruder

machine configurations feature microprocessor-controlled DC drives with torque accuracy within 0.5% across the output range. Industry-leading models now incorporate infrared spectral analysis for real-time wall thickness monitoring, reducing dimensional variance to ±0.15mm. Consider the critical specifications found in premium systems:

| Parameter | Standard Range | High-Performance Models |

|---|---|---|

| Screw Diameter | 45-120mm | 90-250mm |

| L/D Ratio | 25:1 | 30:1-36:1 |

| Max Output | 300 kg/h | 2200 kg/h |

| Energy Consumption | 0.45 kWh/kg | 0.32 kWh/kg |

| Vacuum Calibration | 3-stage | 7-stage with CFD optimization |

Advanced systems incorporate melt pumps achieving pressure consistency of ±1.5% at 550 bar, enabling production of SDR17 pipes meeting ISO 4427 standards with 98.3% material utilization efficiency.

Industry-Leading Manufacturer Comparison

Key players differentiate through proprietary drive systems and specialized components. European manufacturers typically offer superior energy efficiency while Asian builders provide competitive entry-level solutions:

| Manufacturer | Torque Density (Nm/cm³) | Maintenance Interval | Smart Controls | Standard Warranty |

|---|---|---|---|---|

| KraussMaffei | 9.5 | 4,500 hours | APC Plus | 5 years |

| Milacron | 8.7 | 3,800 hours | SmartMold | 3 years |

| Battenfeld | 9.1 | 5,000 hours | BCtouch | 4 years |

| Chinese OEM | 6.3 | 2,200 hours | Basic PLC | 18 months |

Mid-market models demonstrate 15-22% faster ROI than entry-level equipment when processing recycled HDPE blends, despite higher initial hdpe extruder machine price points. Top-tier extrusion lines maintain tolerance consistency 3.8x better than economy models during continuous 24/7 operation.

Custom Engineering Solutions

Specialized applications demand configuration adjustments for optimal performance. Mining pipe systems require reinforced screw flights hardened to 60 HRC, increasing wear resistance by 300% when processing carbon-black compounded HDPE. For corrugated pipe production, tandem extrusion systems with separate melt paths maintain distinct temperature profiles in outer (121°C) and inner (118°C) layers to prevent interface deformation. Co-extrusion adaptations enable 8-layer barrier pipes for chemical transport applications, achieving permeability rates below 0.005 g/m²/day through fluoropolymer laminations.

Documented Application Performance Metrics

Water infrastructure projects reveal measurable differences between extruder classes in field conditions. Municipal pipe production data from German manufacturer indicates:

• DN1200mm pipes produced with 1000mm/s puller speed achieved dimensional stability of ≤0.3% ovality

• 78% reduction in fusion joint failures by implementing inline ovality correction modules

• 92% energy recovery from servo-regenerative braking during haul-off cycling

• 4.2-ton reduction in carbon emissions annually per line through optimized barrel insulation

Geothermal pipe applications demonstrated unexpected outcomes when transitioning from single to dual-screw systems, with wall concentricity improving from 96.2% to 99.7% while reducing gel particle formation by 89%.

Investment Analysis and Operational Economics

Total ownership costs reveal significant variance across equipment tiers. Premium European hdpe extruder machine installations average $850,000 with 5-year maintenance costs at 18% of CAPEX versus Chinese counterparts at $350,000 with maintenance consuming 32% of initial investment. Energy consumption patterns demonstrate that:

• High-efficiency DC drives save approximately $18,600 annually per line at 1,200kg/h output

• Advanced thermal systems recover 43% of barrel heat energy

• Automatic gauge control reduces material waste to 2.1% versus 6.8% in manual systems

• Mean time between failures increases from 1,400 hours to 5,000 hours with premium gearboxes

Operational metrics prove that higher production quality (≤3% scrap rate) yields greater ROI than maximum throughput configurations generating 12-15% rejection rates.

Advancements in HDPE Extruder Technology

Emerging hdpe extruder innovations focus on hyper-precision control through machine learning algorithms. Pilot programs demonstrate adaptive extrusion systems predicting screw wear with 97% accuracy, automatically compensating through dynamic temperature profiling. Microwave-based rheology sensors now provide real-time MI measurements every 8 seconds, enabling viscosity adjustments within 0.5 MFI units during material transitions. Solid-state polymer heating technologies show potential to reduce energy consumption below 0.28 kWh/kg while eliminating barrel thermal gradients entirely. The industry is migrating toward fully automated extrusion cells that optimize 23 interdependent parameters simultaneously, elevating OEE to unprecedented levels beyond 92.5%.

(hdpe extruder)

FAQS on hdpe extruder

Q: What is the key difference between HDPE pipe extruders and standard HDPE extruders?

A: HDPE pipe extruders are specialized for manufacturing pipes with precise diameter control and cooling systems, while standard HDPE extruders handle broader applications like sheets or films. Their screw designs and downstream equipment also differ to accommodate pipe-specific requirements.

Q: What factors influence the price of an HDPE extruder machine?

A: HDPE extruder machine prices depend on production capacity, automation level, brand reputation, and additional features like energy efficiency. Customization for specific products (e.g., pipes vs. profiles) and regional market demand also impact costs.

Q: How often does an HDPE extruder machine require maintenance?

A: Basic maintenance like screw cleaning should occur weekly, while major component inspections are recommended monthly. High-quality HDPE extruders with wear-resistant parts may extend service intervals by 20-30% compared to standard models.

Q: What specifications should I check when selecting an HDPE pipe extruder?

A: Focus on screw diameter (40-200mm), L/D ratio (25:1+ for HDPE), maximum output (kg/h), and compatibility with pipe diameter ranges. Verify temperature control precision (±1°C) and availability of vacuum calibration tanks for pipe sizing.

Q: Can one HDPE extruder machine produce multiple product types?

A: Yes, with modular screw/barrel configurations and die changes, many HDPE extruders switch between pipes, profiles, and sheets. However, production transitions typically require 4-8 hours for reconfiguration and calibration.

-

Tube and Pipe ManufacturingNewsMay.14,2025

-

HDPE Pipe Extrusion LineNewsMay.14,2025

-

Automatic Sealing MachinesNewsMay.14,2025

-

PVC Profile Production LineNewsApr.29,2025

-

Pipeline Equipment for SaleNewsApr.29,2025

-

Pipe Extrusion Line for SaleNewsApr.29,2025

-

HDPE Pipe Manufacturing MachineNewsApr.29,2025