- Overview of Plastic Extrusion Equipment

- Technical Advantages Driving Industry Adoption

- Comparative Analysis of Leading Manufacturers

- Custom Solutions for Diverse Production Needs

- Real-World Applications and Case Studies

- Innovations Shaping the Future of Extrusion

- Why Partner with Expert Plastic Extrusion Equipment Manufacturers

(plastic extrusion equipment)

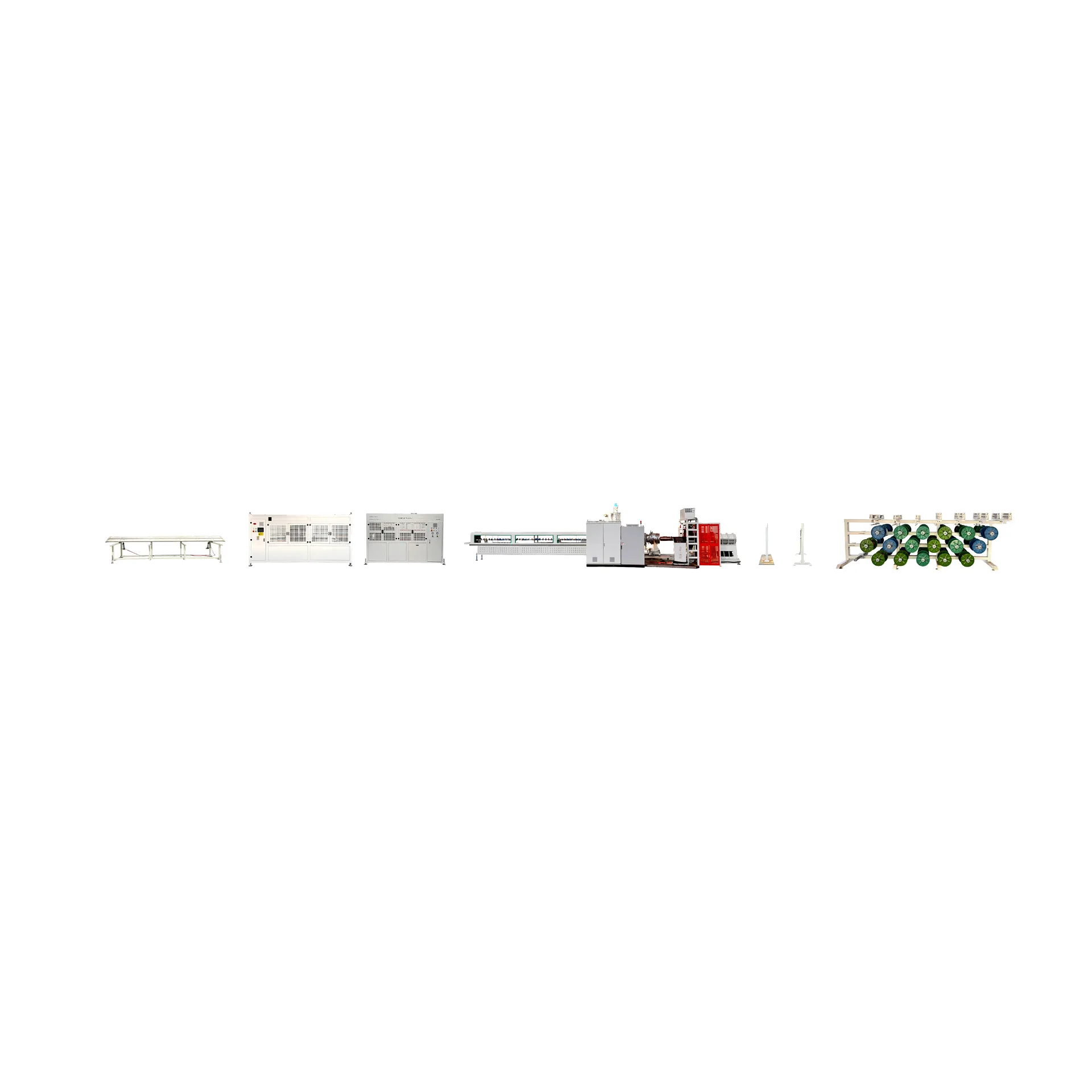

Overview of Plastic Extrusion Equipment

Modern manufacturing relies heavily on plastic extrusion equipment

to produce consistent, high-quality profiles for industries ranging from construction to automotive. This machinery melts raw polymer materials, shapes them through precision dies, and cools the output into finalized products like pipes, sheets, or complex profiles. With a global market projected to reach $84.3 billion by 2028 (CAGR 4.6%), advancements in extrusion technology are critical for meeting sustainability and efficiency demands.

Technical Advantages Driving Industry Adoption

Leading-edge plastic profile extrusion equipment integrates features such as:

- 25-30% energy reduction via servo-driven motors and heat recovery systems.

- Real-time monitoring with IoT-enabled sensors to minimize defects (<1% reject rate).

- Multi-layer extrusion capabilities for enhanced product durability.

These innovations enable manufacturers to achieve throughput speeds exceeding 1,200 kg/hour while maintaining ±0.05mm dimensional accuracy.

Comparative Analysis of Leading Manufacturers

| Manufacturer | Output Capacity | Energy Efficiency | Customization |

|---|---|---|---|

| Company A | 1,400 kg/h | 88% | Full tooling adaptation |

| Company B | 1,100 kg/h | 92% | Modular die systems |

| Company C | 950 kg/h | 85% | Limited to standard profiles |

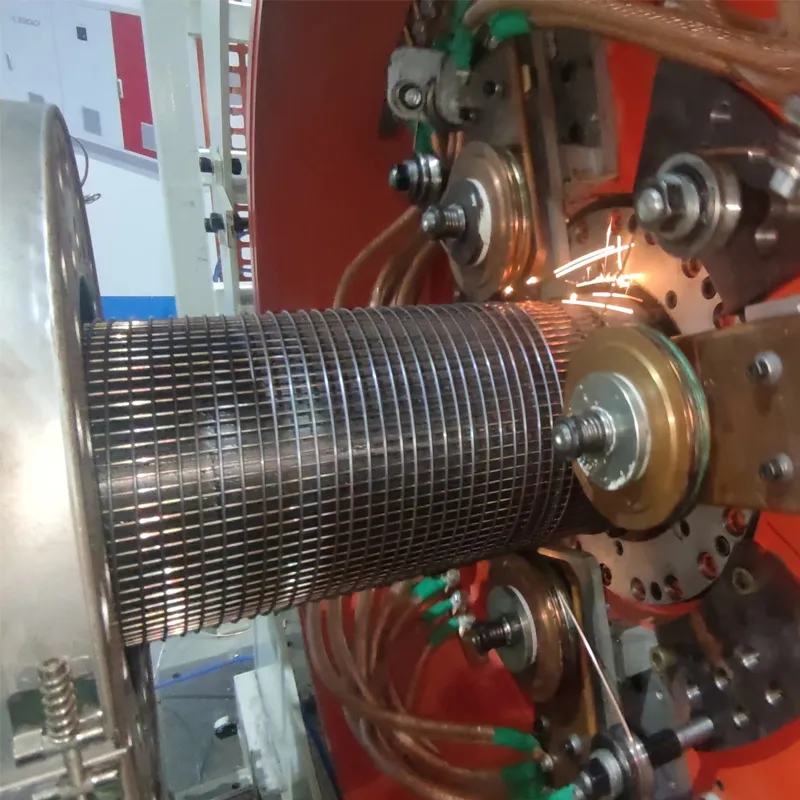

Custom Solutions for Diverse Production Needs

Specialized plastic extrusion equipment manufacturers now offer:

- Co-extrusion systems for barrier layers in packaging films.

- UV-resistant compound compatibility for outdoor applications.

- Quick-change die assemblies reducing downtime by 40%.

A recent automotive project required 6-layer tubing with conductivity properties – achieved through customized screw designs and temperature zoning.

Real-World Applications and Case Studies

Extrusion technology powers critical components across sectors:

- Construction: PVC window profiles with 60-year lifespans.

- Medical: Silicone tubing meeting ISO 13485 standards.

- Renewables: Solar panel framing extruded at 18m/min.

Innovations Shaping the Future of Extrusion

Emerging trends include AI-driven predictive maintenance (reducing downtime by 25%) and biodegradable polymer processing at industrial scales. Nano-additive integration now enhances product strength by 200% without compromising extrusion speeds.

Why Partner with Expert Plastic Extrusion Equipment Manufacturers

Selecting established plastic extrusion equipment providers ensures access to R&D-backed technologies and localized technical support. Top-tier manufacturers deliver 98.5% machine uptime guarantees alongside comprehensive material compatibility testing – crucial for maintaining competitive advantage in precision-driven markets.

(plastic extrusion equipment)

FAQS on plastic extrusion equipment

Q: What factors should be considered when choosing plastic extrusion equipment?

A: Key factors include material type, production volume, equipment precision, energy efficiency, and compatibility with specific extrusion processes like profile or sheet extrusion. Always verify technical specifications and after-sales support.

Q: How do plastic extrusion equipment manufacturers ensure quality control?

A: Reputable manufacturers adhere to ISO certifications, conduct rigorous testing, and use advanced technologies like real-time monitoring systems. They also provide documentation and comply with industry standards for safety and performance.

Q: What distinguishes plastic profile extrusion equipment from general extrusion machinery?

A: Profile extrusion equipment is specialized for creating complex cross-sectional shapes (e.g., pipes, window frames) with precise tolerances. It often includes custom dies, advanced cooling systems, and downstream cutting tools tailored for profiles.

Q: What maintenance practices extend the lifespan of plastic extrusion equipment?

A: Regular cleaning of screws and barrels, lubrication of moving parts, and calibration of temperature controls are essential. Schedule preventive maintenance with the manufacturer to address wear and avoid unplanned downtime.

Q: Can plastic extrusion equipment handle recycled materials effectively?

A: Yes, many modern systems are designed with reinforced screws and filtration systems to process recycled plastics. However, material consistency and impurities must be controlled to maintain output quality and equipment efficiency.

-

PVC Profiles: The Future of Durable and Cost-Effective Construction SolutionsNewsJun.06,2025

-

PVC Pipe Extrusion LineNewsJun.06,2025

-

High-Quality Polyethylene Pipe Production LineNewsJun.06,2025

-

High-Performance Tube Production LineNewsJun.06,2025

-

Advanced Plastic Pipe Production LineNewsJun.06,2025

-

Hdpe Steel Wire Mesh Reinforced Polyethylene Skeleton PipeNewsJun.06,2025

-

Tube and Pipe ManufacturingNewsMay.14,2025