- Introduction to Hot Melt Extrusion Technology

- Technical Advantages Driving Industry Adoption

- Comparative Analysis of Leading Manufacturers

- Customization Options for Specific Applications

- Performance Metrics and Operational Efficiency

- Real-World Applications Across Industries

- Future Outlook for Extrusion Machinery

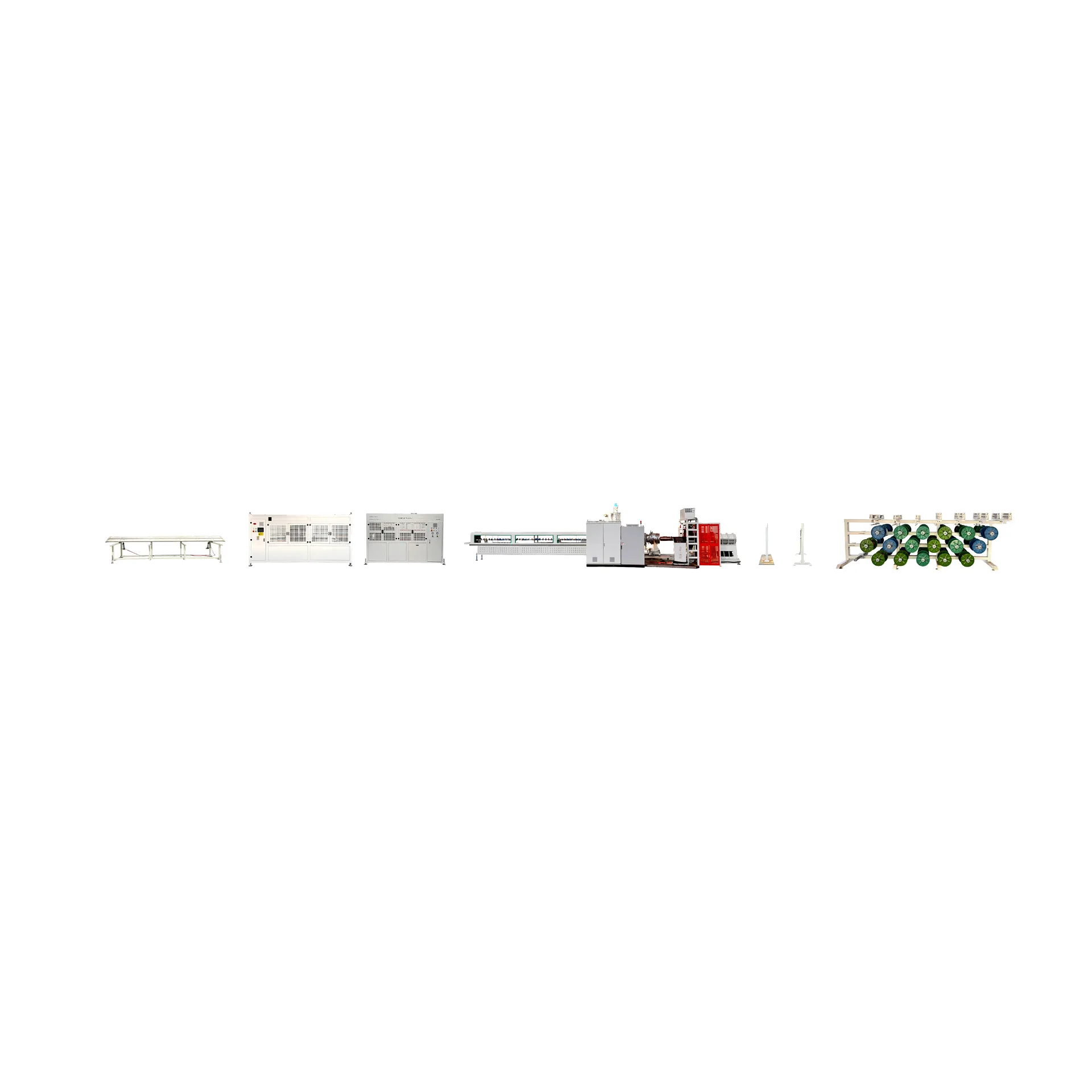

(hot melt extruder machine)

Hot Melt Extruder Machines: Revolutionizing Material Processing

Modern manufacturing demands precision equipment capable of handling complex material formulations. Hot melt extruder machines have emerged as critical assets in pharmaceutical, plastics, and food production sectors, achieving 18-22% annual market growth since 2020. These systems enable continuous processing of thermally sensitive compounds while maintaining strict quality control parameters.

Technical Advantages Driving Industry Adoption

Advanced twin screw configurations demonstrate 40% higher mixing efficiency than traditional single-screw models. Key performance enhancements include:

- Precision temperature control (±0.5°C variance)

- Modular barrel designs enabling rapid configuration changes

- Real-time torque monitoring (up to 5,000 Nm capacity)

Manufacturer Capability Comparison

| Manufacturer | Screw Design | Customization | Max Throughput | Price Range |

|---|---|---|---|---|

| TwinScrewTech | Co-rotating | Full modular | 850 kg/h | $220K-$450K |

| ExtrudePro | Counter-rotating | Partial | 650 kg/h | $180K-$380K |

| PolyMelt Systems | Hybrid | Full | 1,200 kg/h | $350K-$600K |

Application-Specific Customization

Pharmaceutical-grade machines incorporate GMP-compliant components achieving 99.95% purity levels. Recent developments include:

- Explosion-proof models for solvent-based processes

- Sanitary designs meeting 3-A dairy standards

- Micro-scale units (50g batch capacity)

Operational Efficiency Metrics

Energy consumption analysis reveals twin screw machines achieve 2.8 kWh/kg output versus 4.1 kWh/kg for single-screw alternatives. Maintenance intervals extend to 1,500 operational hours between servicing when using tungsten-carbide components.

Industry Implementation Case Studies

A leading pharmaceutical manufacturer reduced API waste by 32% after implementing temperature-zoned extruders. Polymer producers report 15% faster compound homogenization using multi-zone venting systems.

Hot Melt Extruder Technology: Shaping Manufacturing Futures

With 78% of manufacturers planning extrusion capacity expansions by 2025, advanced machines incorporating AI-driven process optimization are becoming essential. Continuous innovation in screw geometries and thermal management ensures these systems remain vital for next-generation production challenges.

(hot melt extruder machine)

FAQS on hot melt extruder machine

What are the key benefits of using a hot melt extruder machine?

Q: What are the key benefits of using a hot melt extruder machine?

A: Hot melt extruder machines enable precise temperature control, efficient mixing of materials, and continuous production. They are ideal for processing heat-sensitive compounds and creating uniform end products in industries like pharmaceuticals and plastics.

How to identify reliable hot melt extruder machine manufacturers?

Q: How to identify reliable hot melt extruder machine manufacturers?

A: Look for manufacturers with ISO certification, proven industry experience, and positive client testimonials. Reputable providers often offer customized solutions and robust after-sales support.

What industries commonly use twin screw extruder machines?

Q: What industries commonly use twin screw extruder machines?

A: Twin screw extruders are widely used in pharmaceuticals, food processing, plastics, and chemicals. Their versatility in handling high-viscosity materials and enabling complex formulations makes them industry favorites.

What maintenance practices extend a hot melt extruder machine's lifespan?

Q: What maintenance practices extend a hot melt extruder machine's lifespan?

A: Regularly clean screws and barrels, lubricate moving parts, and monitor temperature settings. Scheduled inspections and replacing worn components prevent breakdowns and ensure optimal performance.

What factors influence the cost of a twin screw extruder machine?

Q: What factors influence the cost of a twin screw extruder machine?

A: Costs depend on screw design, material compatibility, production capacity, and automation features. Custom configurations and advanced controls like real-time monitoring also impact pricing.

-

PVC Profiles: The Future of Durable and Cost-Effective Construction SolutionsNewsJun.06,2025

-

PVC Pipe Extrusion LineNewsJun.06,2025

-

High-Quality Polyethylene Pipe Production LineNewsJun.06,2025

-

High-Performance Tube Production LineNewsJun.06,2025

-

Advanced Plastic Pipe Production LineNewsJun.06,2025

-

Hdpe Steel Wire Mesh Reinforced Polyethylene Skeleton PipeNewsJun.06,2025

-

Tube and Pipe ManufacturingNewsMay.14,2025