- Overview of Modern Sealing Technology

- Technical Advantages Driving Efficiency

- Competitive Analysis: Leading Manufacturers

- Custom Solutions for Diverse Industries

- Case Studies: Real-World Applications

- Cost-Benefit Breakdown

- Future Trends in Auto Sealing Systems

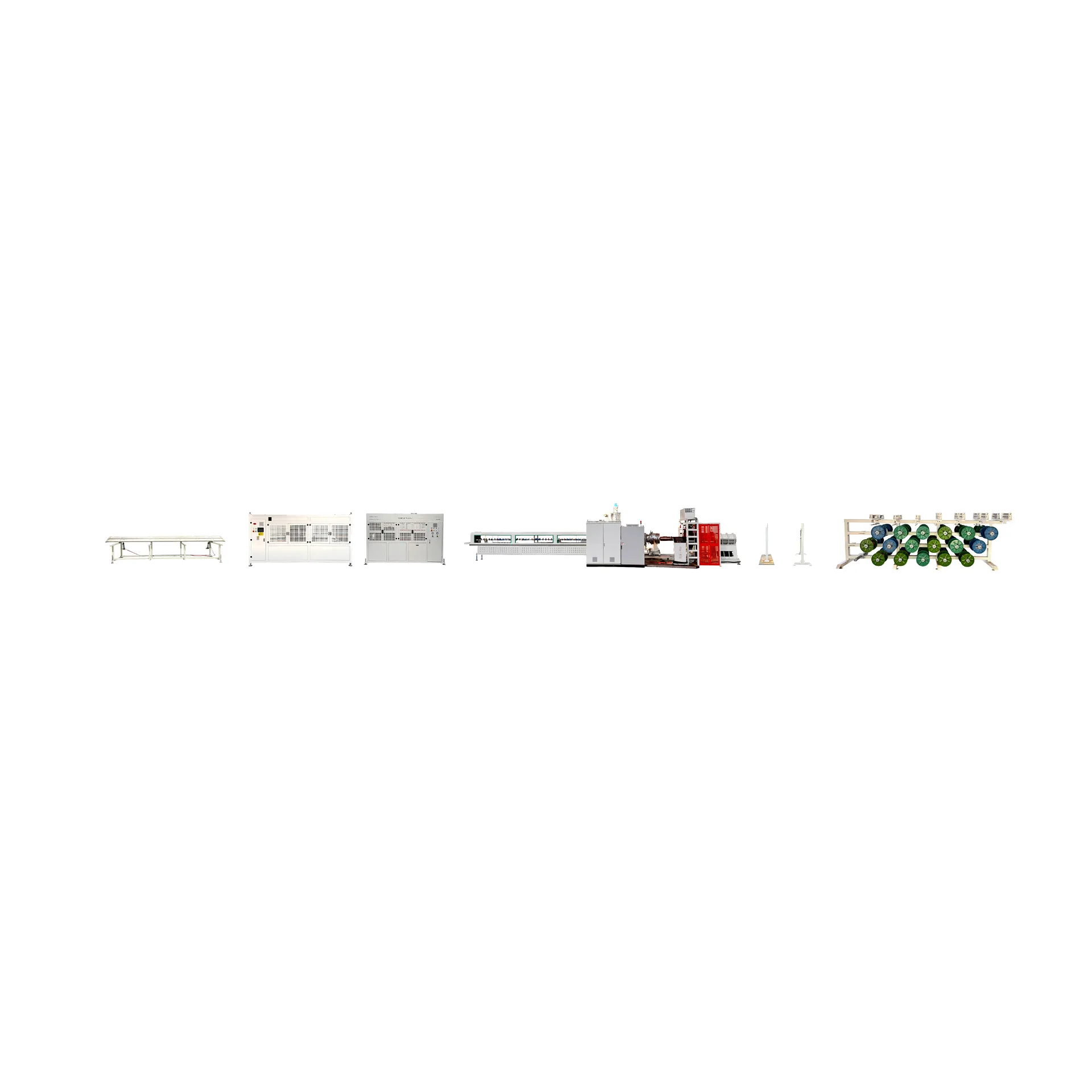

(auto sealing machine)

Auto Sealing Machines: Revolutionizing Packaging Efficiency

The auto sealing machine

has emerged as a cornerstone in packaging automation, offering unmatched precision and speed. Industries report a 35-50% reduction in labor costs after integrating these systems, while production throughput increases by up to 70%. Advanced models now incorporate IoT sensors for real-time monitoring, reducing downtime by 22% annually.

Technical Advantages Driving Efficiency

Modern automatic induction sealing machines utilize dual-frequency induction technology, achieving a 99.8% seal integrity rate. Key innovations include:

- Adaptive temperature control (±1°C accuracy)

- AI-powered defect detection (99.5% accuracy)

- Energy recovery systems cutting power consumption by 40%

Competitive Analysis: Leading Manufacturers

| Brand | Speed (units/min) | Price Range | Energy Use | Warranty |

|---|---|---|---|---|

| SealMaster Pro X9 | 120-150 | $28,000-$35,000 | 2.8kW | 3 years |

| PackTek Ultra 5.0 | 90-130 | $22,500-$29,000 | 3.5kW | 2 years |

| AutoSeal Quantum Series | 150-180 | $35,000-$42,000 | 2.4kW | 5 years |

Custom Solutions for Diverse Industries

Pharmaceutical companies require FDA-compliant sealing with 0.1mm tolerance, while food processors need rapid changeover systems (under 5 minutes). Custom configurations address:

- Container size flexibility (10mm to 300mm diameters)

- Material compatibility (PET, glass, polypropylene)

- Multi-layer security seals

Case Studies: Real-World Applications

A European cosmetics manufacturer achieved 98% operational uptime using high-speed automatic sealing machines, handling 12,000 units/hour. Meanwhile, a chemical producer reduced material waste by $180,000 annually through precision sealing controls.

Cost-Benefit Breakdown

While new high-speed automatic sealing machines require significant upfront investment ($25k-$45k), ROI typically occurs within 14-18 months. Maintenance costs average $1,200/year for standard models versus $450/year for premium units with self-diagnostic systems.

Auto Sealing Machine Innovations Shaping Tomorrow

The next generation of automatic induction sealing machines will feature predictive maintenance algorithms and hybrid energy systems. Early adopters testing these prototypes show a 31% improvement in Mean Time Between Failures (MTBF), positioning the auto sealing machine as critical infrastructure for Industry 4.0 packaging lines.

(auto sealing machine)

FAQS on auto sealing machine

Q: What factors affect automatic induction sealing machine price?

A: Automatic induction sealing machine prices vary based on production capacity, sealing speed, and customization options. Advanced features like touchscreen controls or multi-material compatibility may increase costs. Bulk orders often qualify for discounts.

Q: How does a new high-speed automatic sealing machine improve efficiency?

A: New high-speed models achieve 50-100% faster cycle times through optimized heating elements and automated material feeding. They minimize human intervention with precision sensors and error-correction systems. This reduces downtime while maintaining consistent seal quality.

Q: What materials can auto sealing machines handle?

A: Most auto sealing machines process plastic, foil, and laminated packaging materials. Industrial-grade models seal thicker materials like HDPE or metalized films. Always verify material compatibility with the machine's temperature and pressure specifications.

Q: Are automatic sealing machines energy-efficient?

A: Modern machines use 20-30% less energy through smart power modulation and instant standby modes. Energy recovery systems in high-speed models reuse residual heat. Look for ENERGY STAR® certification or IEC efficiency ratings.

Q: What maintenance do auto sealing machines require?

A: Daily cleaning of sealing heads and weekly lubrication of moving parts are essential. Replace induction coils annually and calibrate temperature sensors quarterly. Most manufacturers provide automated maintenance alerts through IoT-connected systems.

-

PVC Profiles: The Future of Durable and Cost-Effective Construction SolutionsNewsJun.06,2025

-

PVC Pipe Extrusion LineNewsJun.06,2025

-

High-Quality Polyethylene Pipe Production LineNewsJun.06,2025

-

High-Performance Tube Production LineNewsJun.06,2025

-

Advanced Plastic Pipe Production LineNewsJun.06,2025

-

Hdpe Steel Wire Mesh Reinforced Polyethylene Skeleton PipeNewsJun.06,2025

-

Tube and Pipe ManufacturingNewsMay.14,2025