- Overview of Industrial Extruders in Modern Manufacturing

- Technical Advantages Driving Efficiency

- Comparative Analysis of Leading Manufacturers

- Custom Solutions for Diverse Production Needs

- Real-World Applications Across Industries

- Maintenance Best Practices for Longevity

- Why Industrial Extruders Remain Essential

(industrial extruder)

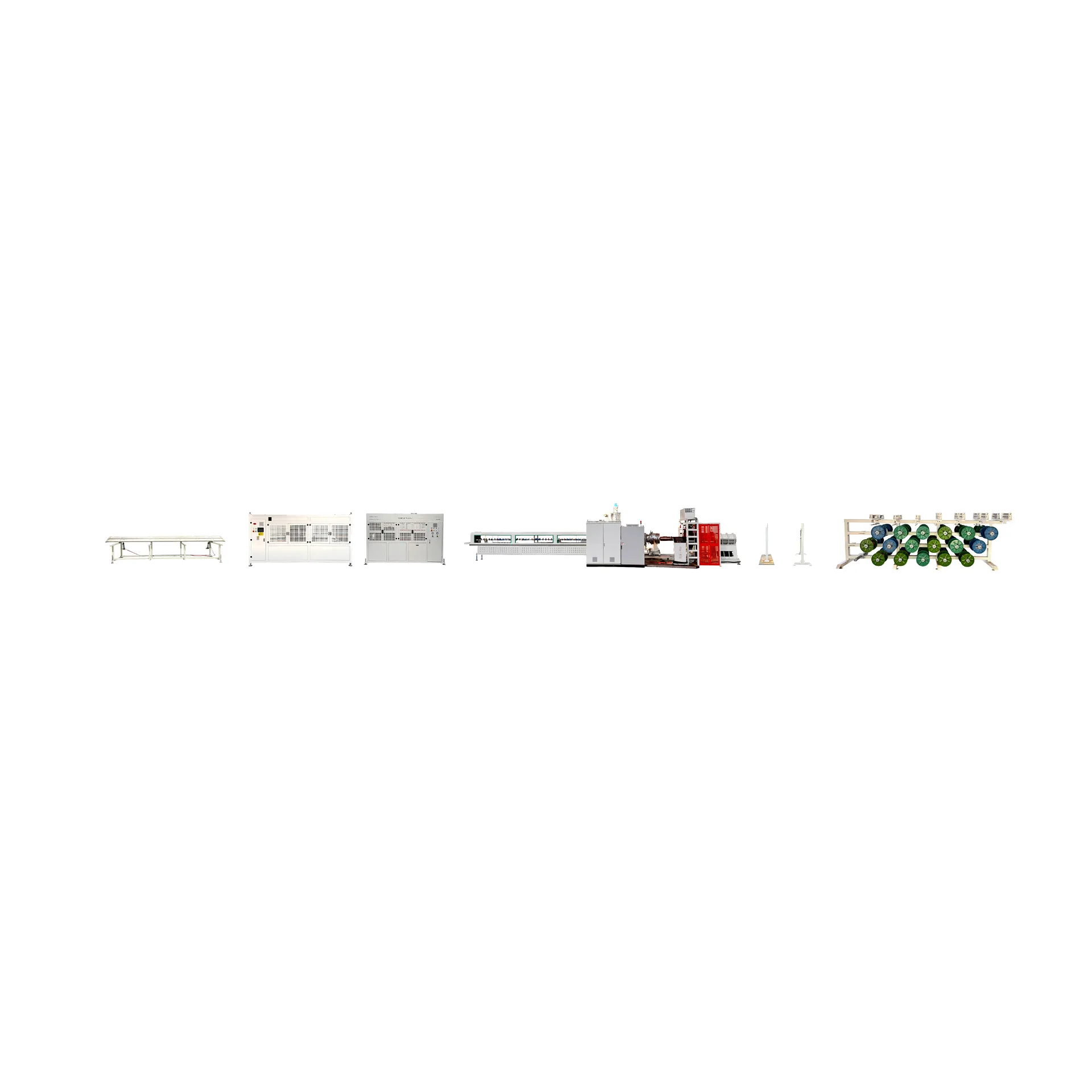

Industrial Extruders: Powering Precision in Manufacturing

Modern production lines rely on industrial extruder

s to transform raw polymers into uniform sheets, films, and profiles. These machines account for 68% of global plastic sheet production, with advanced models achieving thickness tolerances within ±0.15mm. The growing demand for plastic sheet extruders reflects increased packaging needs across food, pharmaceutical, and construction sectors—projected to grow at 5.2% CAGR through 2029.

Technical Advantages Driving Efficiency

Contemporary sheet extruder machines integrate three critical innovations:

- Co-rotating twin-screw designs (18-24% higher output vs. single-screw models)

- Adaptive thermal control systems (±1°C stability)

- AI-driven thickness monitoring (98.6% consistency rate)

Energy consumption benchmarks show 12-15% reduction per metric ton compared to 2020 models, while production speeds now reach 45 meters/minute for 2mm PVC sheets.

Manufacturer Capability Comparison

| Brand | Max Output (kg/hr) | Energy Use (kWh/kg) | Custom Options |

|---|---|---|---|

| AlphaExtrude Pro | 850 | 0.28 | Modular dies, hybrid heating |

| PolyMast 9000 | 720 | 0.31 | Multi-layer capability |

| ThermoFlex VX | 950 | 0.26 | Rapid material changeover |

Tailored Engineering Solutions

Specialized configurations address unique challenges:

- High-viscosity processing: 30:1 L/D screws with 4000 psi melt pressure

- Temperature-sensitive materials: 5-zone barrel cooling (±0.5°C)

- Rapid product switching: Quick-change die systems (45-minute transition)

Industry-Specific Implementations

A automotive parts supplier achieved 22% material savings using a plastic sheet extruder with real-time thickness adjustment. Construction material producers report 40% faster production of 4m-wide PVC membranes through advanced air-knife calibration.

Operational Longevity Strategies

Preventive maintenance protocols extend machine life by 35-40%:

- Screw and barrel inspections every 800 operating hours

- Gearbox oil analysis quarterly

- Thermocouple calibration every 6 months

Sustained Relevance of Industrial Extrusion

As material science advances, industrial extruders adapt to process bio-polymers and recycled composites with 94% efficiency. The technology continues to enable cost-effective production of precision-engineered plastic components, maintaining its position as the backbone of sheet manufacturing operations worldwide.

(industrial extruder)

FAQS on industrial extruder

Q: What is an industrial extruder used for in manufacturing?

A: An industrial extruder melts and shapes raw materials like plastics into continuous profiles. It’s widely used for producing pipes, sheets, and films. The process ensures high-volume, consistent output for industrial applications.

Q: How does a plastic sheet extruder differ from standard industrial extruders?

A: A plastic sheet extruder is specifically designed to produce flat plastic sheets with uniform thickness. It uses specialized dies and cooling systems compared to general industrial extruders, which may create varied shapes.

Q: What factors should I consider when choosing a sheet extruder machine?

A: Key factors include material type, output capacity, sheet thickness range, and energy efficiency. Also, evaluate the machine’s cooling systems and automation features to match production needs.

Q: What maintenance is required for a plastic sheet extruder?

A: Regularly clean screws and barrels to prevent material buildup. Inspect heaters, dies, and cooling systems for wear. Lubricate moving parts and calibrate temperature controls periodically.

Q: Can a sheet extruder machine handle recycled materials?

A: Yes, many modern sheet extruder machines support recycled plastics. However, material consistency and proper filtration are critical to avoid clogs and ensure product quality.

-

PVC Profiles: The Future of Durable and Cost-Effective Construction SolutionsNewsJun.06,2025

-

PVC Pipe Extrusion LineNewsJun.06,2025

-

High-Quality Polyethylene Pipe Production LineNewsJun.06,2025

-

High-Performance Tube Production LineNewsJun.06,2025

-

Advanced Plastic Pipe Production LineNewsJun.06,2025

-

Hdpe Steel Wire Mesh Reinforced Polyethylene Skeleton PipeNewsJun.06,2025

-

Tube and Pipe ManufacturingNewsMay.14,2025